How Do Rotary Unions Work? Discover the Engineering Behind Leak-Free Rotation

A rotary union—also called a rotary joint, rotary swivel, or rotating union—is a precision mechanical device that allows fluid or gas to flow from a stationary inlet to a rotating machine component without leakage. It is essential in industrial equipment where heating, cooling, lubrication, or hydraulic power must continue even while the system rotates. In essence, a rotary union provides a sealed, rotating passage that allows continuous or intermittent fluid transfer even while the connected component rotates — preserving fluid supply during motion. Rotary unions are widely used in paper machines, plastics processing, CNC machining centers, hydraulic systems, textile equipment, wind turbines, oil & gas systems, and many other industries. In this comprehensive blog post. We’ll peel back the layers of these remarkable mechanical components, exploring their inner workings, key components, and How do Rotary Unions Work.

The Operational Mechanics of Rotary Unions

When a rotary joint is in operation, two components rotate relative to each other, connected at either end. When a medium (liquid, gas) enters the rotary joint from the channel of one component, the rotor, under its rotational motion, transfers the medium to the channel of the other component, achieving media transfer. During this transfer process, seals maintain a tight seal between the two components, preventing leakage. Bearings support and guide the movement of the rotor, ensuring smooth rotation.

1. Key interconnected processes

Fluid Inlet and Initial Direction: When a rotary union is part of a fluid transfer system, fluid enters the union through an inlet port located on the stationary housing. The design of the housing’s internal passages guides the fluid towards the rotating shaft. For example, in a steam-powered industrial dryer, steam enters the rotary union from the steam supply line connected to the stationary housing. The internal channels in the housing direct the steam towards the rotating shaft, preparing it for transfer to the rotating component of the dryer.

Transfer to the Rotating Shaft: As the fluid approaches the rotating shaft, the alignment of the channels in the housing with those in the shaft is critical. The precise machining of both components ensures a seamless transition of the fluid from the stationary to the rotating part. The rotating shaft, in turn, carries the fluid along with it as it rotates. In a hydraulic system using a rotary union, hydraulic oil enters the shaft’s channels and is then distributed to the various hydraulic actuators on the rotating machinery. This transfer of fluid while the shaft is in motion is what sets rotary unions apart from traditional static fluid connectors.

Sealing Mechanism in Action: While the fluid is being transferred, the seals play a crucial role in preventing leakage. The mechanical seals, for example, maintain constant contact between the stationary and rotating faces. As the shaft rotates, the seals adapt to any minor variations in the shaft’s position or surface irregularities, ensuring a tight seal at all times.

Fluid Distribution on the Rotating Side: Once the fluid reaches the rotating side, the rotating shaft and its connected component distribute it according to the design. In a paper machine’s drying cylinder, the rotary union transfers steam through internal passages in the cylinder, ensuring even surface heating. In a textile finishing machine, the rotary union delivers water or steam to spread evenly for steaming and pressing the fabric.

2. Graphic Display

Different rotary joint specifications and models have different working principles. Below, we’ll explain the working principles of rotary joints intuitively, using diagrams and text based on their flow patterns.

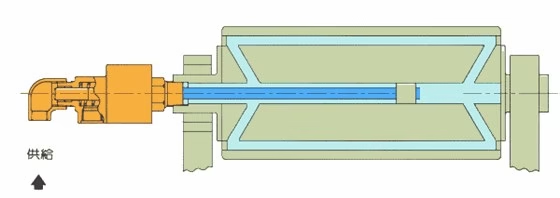

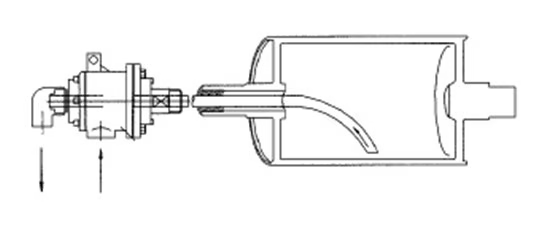

2.1 Double-Way (Inner Tube Rotating) Rotary Joint Working Principle

This type provides a tight connection between the inner tube and the inner fluid passageway of the drum to prevent fluid backflow and affect the drum’s heating efficiency. The inner tube and drum operate synchronously.

Joint Working Schematic

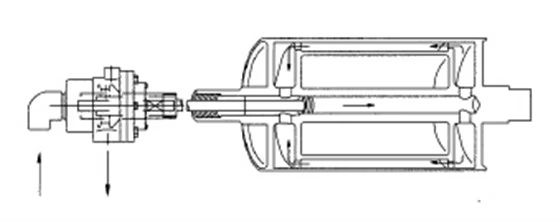

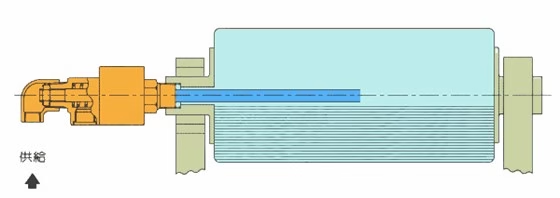

2.2 Two-Way (Fixed Inner Tube) Rotary Joint

This type differs in that a siphon tube is installed inside the drum to drain condensate. This type is primarily used for steam.

Joint Working Diagram

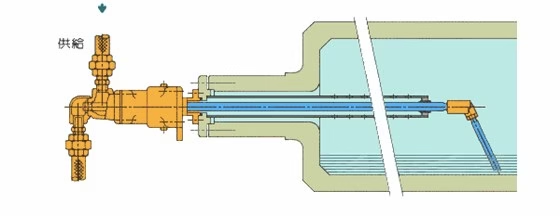

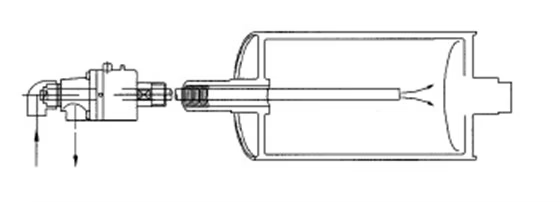

2.3 Double-pass (Fixed Inner Tube) Rotary Joint

A rotary joint is installed at one end of the drum, providing both fluid inlet and outlet functions.

A rotary joint is installed at one end of the drum, providing both fluid inlet and outlet functions.

Joint Operation Diagram

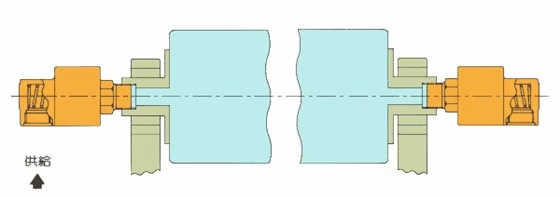

2.4 Single-pass rotary joints

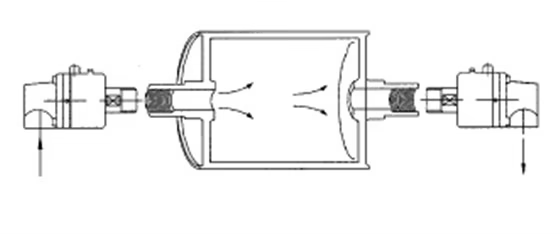

Swivel joints installed at both ends of the drum provide a through-flow system, allowing fluid to enter at one end and exit at the other, eliminating the need for an internal pipe.

Swivel joints installed at both ends of the drum provide a through-flow system, allowing fluid to enter at one end and exit at the other, eliminating the need for an internal pipe.

Joint operation diagram:

Working Principle — How Rotary Unions Actually Work

Here’s a step-by-step overview of the typical working process of a rotary union:

Connection to Stationary Supply

A stationary supply line connects to the housing (or inlet port) of the rotary union and supplies fluid such as steam, coolant, oil, or compressed air. This is the “fixed” end of the system.

Attachment to Rotating Equipment

The shaft (or housing, depending on design) of the union is connected to the rotating component of the machinery — for example, a drum, roll, rotor, or spindle. During machine operation, this part rotates, carrying media into or out of the rotating component.

Sealing Interface Maintains Separation

Inside the union, seals and bearings isolate the stationary part from the rotating part. The seal(s) create a tight barrier preventing fluid (or gas) from leaking out even under rotation and pressure. Bearings ensure smooth rotation without excessive friction or wear.

Continuous or Intermittent Fluid Transfer During Rotation

As long as the seal integrity remains intact and the union is properly designed for the fluid type, pressure, temperature, and rotational speed, fluid or gas continuously flows through the union into (or out of) the rotating machine component — enabling the machine to perform its function (cooling, heating, lubrication, hydraulic actuation, etc.) without disruption.

Optional Dual-Flow or Multi-Pass Operation

Some rotary unions are designed with multiple channels/ports, allowing different media (or supply + return) to flow simultaneously without interfering with each other. Seals inside separate the passages.

Step-by-Step: How do Rotary Unions Work

Although designs vary by media, pressure, temperature, and speed, all rotary unions follow the same fundamental working principle:

Step 1: Fluid enters the stationary housing

The housing connects to the fixed fluid supply line. Fluid enters through an inlet port.

Step 2: The rotating shaft carries fluid into the machine

The internal rotor/shaft connects to the rotating equipment, such as:

-

Drums

-

Rolls

-

Cylinders

-

Spindles

-

Turrets

-

Indexing tables

When the machine rotates, the shaft rotates with it.

Step 3: Bearings support rotation

High-precision bearings—ball, roller, or hybrid types—ensure smooth rotation while managing radial and axial loads.

Step 4: Seals prevent leakage

The seal interface is the heart of the rotary union. It keeps fluid contained while allowing rotation. Depending on the application, seals may be:

-

Mechanical seals (most common)

-

Carbon-graphite seals

-

O-ring seals

-

Lip seals

-

Hydrostatic or non-contact seals

Step 5: Fluid exits into the rotating equipment

Fluid flows through the shaft and enters the rotating drum or component, performing its intended function, such as:

-

Heating (steam/thermal oil)

-

Cooling (water/glycol)

-

Lubrication (oil)

-

Pneumatic actuation (air)

-

Hydraulic power transfer

Step 6: Return flow or additional media (optional)

Multi-pass rotary unions allow:

-

Supply + return

-

Multiple independent media

-

Different pressures

-

Different temperatures

Internal seals prevent cross-contamination.

This process enables continuous fluid transfer without twisting hoses, leaking joints, or interrupted flow.

Rotary Unions in Different Fluid Applications

Rotary unions are versatile devices that can handle a wide variety of fluids, each with its unique characteristics and requirements. How do Rotary Unions Work?

Steam Applications

In steam applications, rotary unions face high-temperature and high-pressure conditions. The seals used in steam rotary unions must be able to withstand these harsh environments without deteriorating. Engineers commonly use graphite-based seals for their excellent heat resistance and sealing properties. They also construct the housing and other components from materials that endure the thermal stress caused by steam.

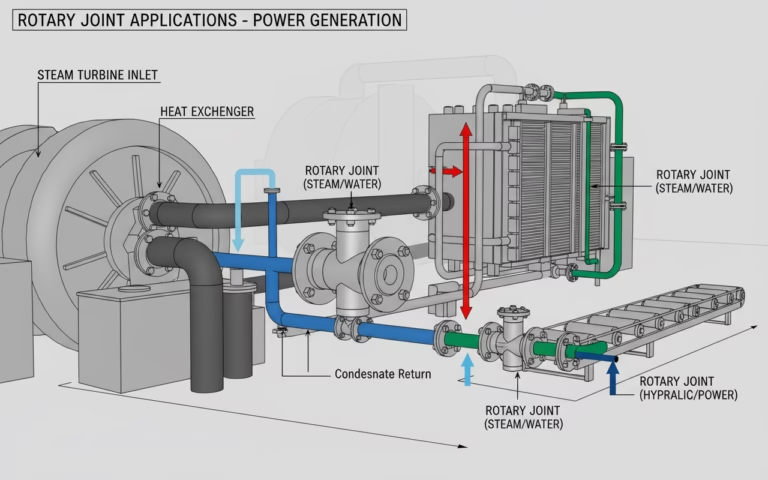

Steam rotary unions are used in numerous industries, such as paper manufacturing, where they supply steam to drying cylinders, and power generation, where they transfer steam to turbines. In these applications, the proper functioning of the rotary union is crucial for maintaining the efficiency of the steam-powered processes.

Hydraulic Oil Applications

For hydraulic systems, rotary unions need to handle high-pressure fluid flow and ensure smooth rotation. The bearings in hydraulic rotary unions are designed to support the heavy loads associated with hydraulic systems. The seals must prevent leakage of the hydraulic oil, which can be costly and may also lead to system failures. Construction equipment, such as excavators and cranes, uses hydraulic rotary unions to transfer hydraulic fluid to rotating arms and joints, enabling precise movement and operation.

Water Applications

Water-handling rotary unions are used in various applications, from cooling systems to water-jet cutting machines. In cooling systems, they transfer water between the stationary and rotating parts of the equipment, helping to dissipate heat. The seals in water rotary unions need to prevent water leakage, which could cause damage to the surrounding machinery or create safety hazards. In water-jet cutting, the rotary union ensures a continuous and high-pressure supply of water to the cutting nozzle, even as the cutting head rotates.

Air Applications

In air-powered systems, rotary unions are responsible for delivering compressed air to rotating components. They need to maintain the air pressure and prevent air leaks, which can reduce the efficiency of the equipment. Air rotary unions are used in pneumatic tools, such as air compressors and nail guns, as well as in industrial automation systems where precise control of air-powered actuators is required.

Applications of Rotary Unions Across Industries

Industries widely use rotary joints in equipment and machinery that transfer liquids or gases. For example, rotary joints transfer hydraulic oil, fuel, or water in oil rigs, printing presses, paper machines, and wind turbine generators, enabling the machines to rotate freely. How do Rotary Unions Work?

Manufacturing Industry

In the manufacturing industry, rotary unions are used in a wide range of equipment. Injection molding machines, for example, use rotary unions to transfer cooling water to the molds, ensuring efficient cooling and proper shaping of the plastic parts. In metalworking, rotary unions are employed in machining centers to supply coolant to the cutting tools, which helps to remove chips and keep the tools cool. The ability of rotary unions to enable fluid transfer during rotation allows for continuous operation of these manufacturing processes, increasing productivity and reducing downtime.

Energy Sector

In the energy sector, rotary unions play a vital role in power generation. In thermal power plants, steam rotary unions transfer steam from the boilers to the turbines, facilitating the conversion of thermal energy into mechanical energy. And in wind turbines, hydraulic rotary unions are used to transfer hydraulic fluid for pitch control systems, which adjust the angle of the turbine blades to optimize power generation. These applications highlight the importance of rotary unions in ensuring the reliable operation of energy-producing equipment.

Food and Beverage Industry

The food and beverage industry uses rotary unions in equipment such as rotary cookers, pasteurizers, and packaging machines. In rotary cookers, steam rotary unions supply steam for cooking food products, ensuring even heating and consistent quality. And in packaging machines, air rotary unions are used to operate pneumatic cylinders that seal the packages. The use of rotary unions in this industry requires strict hygiene standards, and manufacturers often use materials that are food-grade and easy to clean to prevent contamination.

Automotive Industry

The automotive industry uses rotary unions in various manufacturing processes. For example, in the production of car tires, rotary unions transfer steam to the tire curing presses, which shape and vulcanize the tires.

Automotive assembly lines use hydraulic rotary unions to power robotic arms, enabling precise movements for tasks like welding and painting. The reliability and performance of rotary unions in the automotive industry are essential for maintaining high-quality production and meeting production deadlines.

Maintenance and Troubleshooting of Rotary Unions

To ensure the long-term reliability and optimal performance of rotary unions, regular maintenance is essential. How do Rotary Unions Work

Regular Inspection

Periodic inspections of rotary unions can help identify potential issues before they become major problems. During an inspection, technicians should check for signs of leakage, wear on the seals and bearings, and any unusual vibrations or noises. Visual inspection of the housing for cracks or corrosion is also important. Operators should take immediate action to address any detected abnormalities.

Lubrication

Proper lubrication of the bearings in rotary unions is crucial for their smooth operation. Manufacturers usually provide specific guidelines on the type of lubricant to use and the frequency of lubrication. Over-lubrication or under-lubrication can both lead to bearing failure, so it’s important to follow the recommended lubrication schedule.

Seal Replacement

Seals have a limited lifespan and will eventually wear out. When signs of seal leakage are observed, it’s necessary to replace the seals promptly. Choosing the right replacement seals based on the application requirements is essential to ensure a proper seal and prevent future leakage.

Troubleshooting Common Issues

Some common issues with rotary unions include leakage, excessive friction, and vibration. Leakage is often caused by worn-out seals or improper installation. Excessive friction can be due to a lack of lubrication, misalignment of the shaft, or damaged bearings. Vibration may result from unbalanced rotating components, worn-out bearings, or loose fittings. Troubleshooting these issues requires a systematic approach, starting with a thorough inspection of the rotary union and its associated components.

Selecting the Right Rotary Union

When choosing a rotary union, you must consider several factors to ensure it meets the specific application requirements. How do Rotary Unions Work

Fluid Type and Properties

The type of fluid the rotary union will handle. Along with its properties such as temperature, pressure, viscosity, and chemical composition, it is a primary consideration. Different fluids require different materials and seal designs to ensure compatibility and prevent leakage.

Operating Conditions

The operating pressure, temperature, and rotational speed of the equipment are also important factors. The rotary union must withstand these operating conditions without failing. For example, a high-speed application will require a rotary union with bearings and seals that can withstand the increased centrifugal forces.

Installation and Space Constraints

You must consider the available installation space and the required connection type (threaded, flanged, etc.). The union should fit seamlessly into the existing system without causing any interference or requiring major modifications.

Maintenance Requirements

Consider the ease of maintenance and the availability of spare parts when selecting a rotary union. A union that is easy to maintain and has readily available replacement components will reduce downtime and maintenance costs in the long run.

Conclusion

Through their structure and operating principle, rotary joints achieve both media transfer and sealing between two relatively rotating components. They play a vital role in the industrial field, providing essential support and assurance for the normal operation of machinery and equipment. They are remarkable mechanical devices that play a crucial role in a wide range of industrial applications. Their ability to transfer fluids between stationary and rotating components while maintaining a secure seal is essential for the efficient operation of countless machines and systems. By understanding how rotary unions work, from their key elements to their operational mechanics, and by considering factors such as fluid type, operating conditions.

And maintenance requirements, industries can select the right rotary unions and ensure their long-term reliability. Regular maintenance and proper troubleshooting are also crucial for maximizing the performance and lifespan of these essential components. As industries continue to evolve and demand more efficient and reliable fluid transfer solutions, rotary unions will undoubtedly remain a cornerstone of industrial machinery.