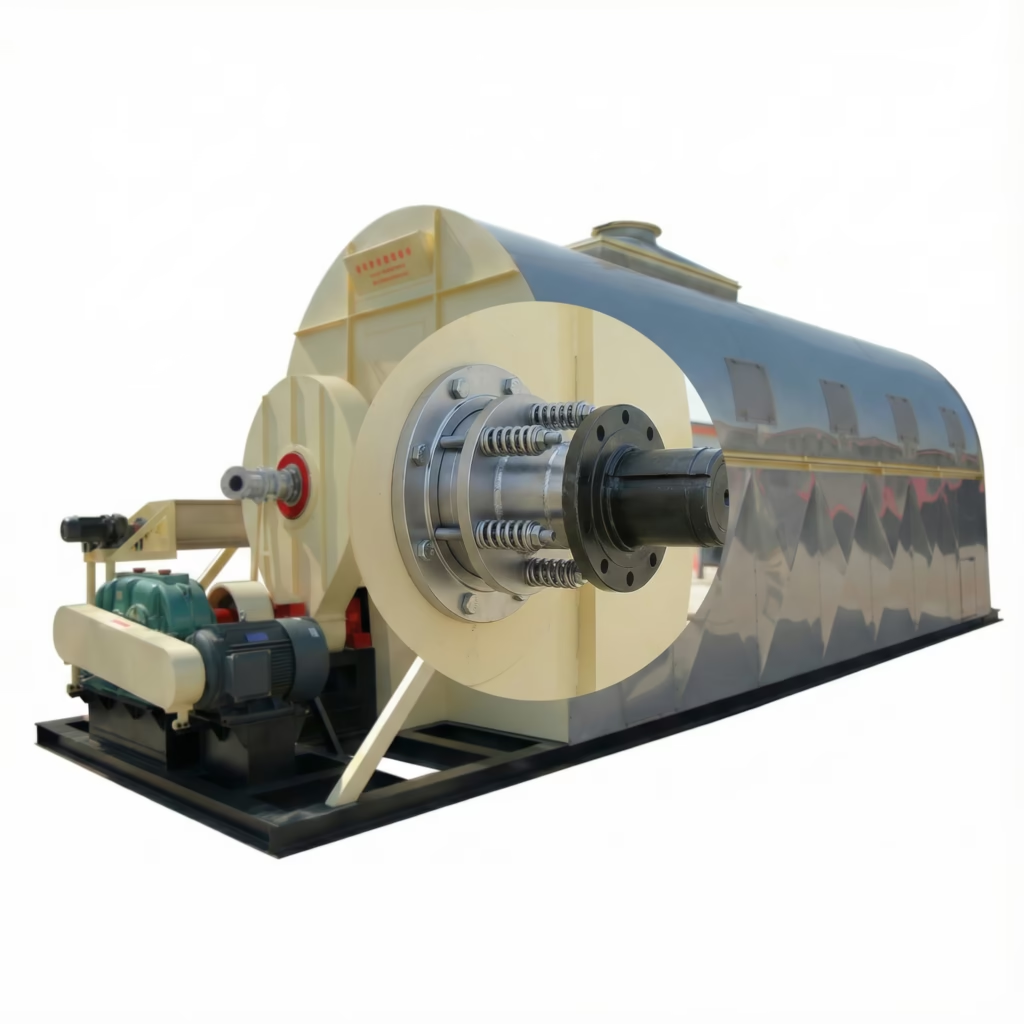

Pipe Bundle Dryer Machine Rotary Joint for starch industry

Original price was: $70.00.$55.00Current price is: $55.00.

- Speed: ≤100QPM

- Temperature: ≤220℃

- Pressure: ≤1.8MPa

- Applicable medium: steam, heat transfer oil

- Specifications: 20, 25, 32, 40, 50, 65, 80, 100, 125, 150

Description

Product Overview: Pipe Bundle Dryer Machine Rotary Joint

The Pipe Bundle Dryer Machine Rotary Joint is a specialized rotary union engineered specifically for tube bundle dryers used in the starch industry. Designed to operate reliably under demanding thermal and pressure conditions, this rotary joint ensures efficient steam or thermal oil transfer between stationary pipelines and rotating dryer cylinders.

With its double spherical sealing ring structure, the joint provides automatic alignment and compensation, making it ideal for equipment with low rotation accuracy, poor concentricity, or frequent thermal expansion. This advanced sealing technology significantly enhances reliability, reduces maintenance frequency, and extends operational lifespan.

This rotary joint is widely applied in:

-

Starch processing plants

-

Tube bundle drying systems

-

Industrial steam heating applications

-

Heat transfer oil circulation systems

-

Large-capacity drying and evaporation equipment

How the Pipe Bundle Dryer Machine Rotary Joint Works

The rotary joint connects the stationary steam supply pipe to the rotating pipe bundle drum.

-

Steam Entry – Steam enters through the fixed side and passes through the rotary joint into the rotating bundle.

-

Heat Transfer – The hot steam flows inside the tubes, heating and drying the starch efficiently.

-

Condensate Discharge – The rotary joint simultaneously allows condensate to exit through a separate channel, maintaining consistent drying performance.

By providing continuous, leak-free rotation, the rotary joint ensures stable heat transfer, minimizes energy loss, and enhances the uniformity of starch drying.

Key Features of Pipe Bundle Dryer Machine Rotary Joint

Double Spherical Sealing Ring Design

- Automatically adjusts and positions under rotation

- Compensates for misalignment and vibration

- Ensures stable sealing even at high temperatures

- Significantly reduces leakage and maintenance requirements

Engineered for Starch Industry Tube Bundle Dryers

- Specifically optimized for pipe bundle dryer rotation conditions

- Handles low concentricity and mechanical tolerances common in starch production lines

High-Quality Materials for Extended Lifespan

- Precision-machined spherical surfaces

- Corrosion-resistant materials suitable for steam and thermal oil

- Robust structure designed for long-term industrial operation

Wide Media Compatibility

- Steam

- Heat transfer oil

- Hot air or other thermal fluids

Low Maintenance & Easy Installation

- Sealing structure designed for rapid replacement

- Compatible with various dryer brands and international standards

Design Highlights of Pipe Bundle Dryer Machine Rotary Joint

Advanced Mechanical Seal Technology

The rotary union seal employs a balanced mechanical sealing structure, minimizing face wear and reducing energy loss.

Its low-friction seal pair (carbon vs. silicon carbide) maintains consistent performance under thermal stress and high rotational speeds.

Independent Flow Paths

The design supports dual flow paths for steam and condensate, preventing backflow and ensuring efficient condensate evacuation from the dryer drum.

Rugged Bearing Support

High-precision dual ball bearings or graphite bushings provide stable rotation and resist vibration caused by the rotating pipe bundle.

Corrosion Protection

All wetted parts are manufactured from stainless steel or plated alloy, preventing corrosion from process steam and condensate impurities.

Why It’s Ideal for the Starch Industry

In starch production, maintaining consistent drying temperature and humidity control is critical to final product quality.

The Pipe Bundle Dryer Rotary Joint ensures:

-

Uniform heat distribution across the drying tubes

-

Controlled condensate drainage for efficient moisture removal

-

Stable mechanical rotation without vibration or seal failure

This results in improved starch purity, shorter drying times, and reduced operational costs — making it a preferred choice for modern starch factories worldwide.

Why Choose our Pipe Bundle Dryer Machine Rotary Joint

-

10+ years of experience in rotary joint and rotary union manufacturing

-

Full compatibility with Deublin, Maier, and Kadant models

-

Factory-direct pricing with OEM customization

-

Fast delivery and technical support

-

Proven performance in the starch and chemical industries

We help you reduce downtime, improve drying efficiency, and extend the life of your equipment.