Rotary Joints for Casting and Rolling Mills: Core Technology Analysis and Application Practices

In the demanding world of nonferrous metal processing, the performance of Rotary Joints for Casting and Rolling Mills is paramount. Its operational stability and efficiency are direct determinants of final product quality and overall production throughput. While massive rollers and powerful motors often take the spotlight, a smaller, highly engineered component plays an equally critical role: the rotary joint. As the core device connecting stationary supply lines to rotating rolls, the rotary joint is the lifeline for essential media like coolants, lubricants, and hydraulic fluids. The integrity of this fluid transfer system is fundamental to the entire casting and rolling process. This article provides a systematic analysis of the core technology, structural design principles, and practical applications of Rotary Joints for Casting and Rolling Mills. We will explore the key technical features that define their performance and look ahead to the future development trends shaping the industry.

I. The Critical Function of Rotary Joints in Casting and Rolling Mills

Casting and rolling mills—especially those processing materials like aluminum and copper—operate under conditions of extreme heat, pressure, and speed. To manage these forces and produce a high-quality cast strip, the rolls require a continuous and precisely controlled supply of fluids. This is where the rotary joint, also known as a rotary union or rotating union, becomes indispensable.

Think of a rotary joint as the sophisticated “hub” for media transmission. It creates a reliable seal between a stationary pipe and a rotating component (the roll or cylinder), allowing fluids to pass between them without leakage. Its primary functions include:

Thermal Management: The system delivers high-volume coolant, typically water or emulsion, to the interior channels of the rolls. This process dissipates the immense heat generated during casting and rolling. Proper temperature control is vital for managing the metal’s solidification. Additionally, it prevents thermal stress. Moreover, it maintains the desired metallurgical properties of the final product.

Lubrication: Supplying lubricating oil or grease to the bearings and other moving parts within the roll assembly. Effective lubrication minimizes friction, reduces wear and tear on the rolls, and lowers energy consumption.

Hydraulic Actuation: In some advanced systems, rotary joints transmit hydraulic fluid to power internal mechanisms within the rolls, such as those for adjusting the roll gap or profile.

The importance of a high-performance rotary joint cannot be overstated. A failure—even a minor leak—can lead to catastrophic consequences. Inadequate cooling can cause roll deformation and defects in the cast strip, such as cracking or inconsistent thickness. A loss of lubrication can result in premature bearing failure, leading to costly unplanned downtime and roll replacement. Therefore, the reliability and performance of the **rotary joint for casting and rolling mills** directly impact temperature control accuracy, lubrication effectiveness, equipment longevity, and, ultimately, the plant’s profitability.

II. Key Technical Features of Rotary Joints for Casting and Rolling Mills

The harsh operating environment of a casting and rolling mill demands a rotary joint with a unique combination of strength, precision, and durability. These solutions engineers design to withstand specific challenges instead of producing off-the-shelf components. Below are the core technical features that define a superior rotary joint for this application.

High-Pressure Tolerance and Structural Integrity

During operation, the fluids passing through the rotary joint are often under significant pressure. Coolant systems can easily exceed 10 MPa (1450 PSI), while hydraulic circuits can operate at much higher levels. Consequently, these rotary joints must be built for extreme durability.

Reinforced Housing: We typically machine the body of the joint from robust materials like high-strength carbon steel, stainless steel, or ductile iron. The housing features thick walls, and to ensure it can withstand pressures exceeding 40 MPa in demanding applications, we often perform a stress analysis using Finite Element Analysis (FEA) to eliminate any weak points.

Multi-Layer Sealing: The sealing system is the heart of the joint. To handle high pressure, it often employs a “balanced mechanical seal” design. This design uses the system’s own fluid pressure to help maintain the seal faces in contact, preventing them from being forced apart. This ensures a consistent, leak-proof seal across a wide range of operating pressures.

Optimized High-Speed Performance

Modern casting and rolling mills operate at impressive speeds, with **roll speeds often ranging from 1000 to 3000 RPM**. At these velocities, any imbalance or friction within the rotary joint is magnified, leading to vibration, excessive heat generation, and premature failure.

Precision Bearing Systems: To handle both radial and axial loads and support the rotating components, we equip these joints with high-precision bearings. We commonly use deep groove ball bearings or angular contact ball bearings and select them specifically for their durability and ability to handle high speeds. By strategically placing these bearings, we ensure a smooth, low-friction rotation while minimizing any wobble or runout.

Dynamic Balancing: Every rotating component of the joint is dynamically balanced to extremely tight tolerances. This process minimizes vibration, reducing stress on the bearings and the seal faces. The result is quieter operation, reduced energy consumption, and significantly extended service life.

Multi-Flow Channel Integrated Design

To streamline operations and reduce the number of components on the end of a roll, modern rotary joints often feature an integrated, multi-channel design. This allows a single unit to handle multiple, independent fluid media simultaneously.

Common Configurations: Dual-channel (or dual-flow) rotary joints** are very common, with one channel for fluid inlet and the other for the return outlet. More advanced systems may use three or four channels to accommodate cooling water, lubricating oil, and purge air in a single, compact unit.

Independent Control: High-end multi-port rotary unions are designed to prevent cross-contamination between media. Each flow channel is isolated by its own set of mechanical seals, ensuring, for example, that coolant cannot mix with hydraulic oil. This integrated approach simplifies plumbing, reduces the machine’s overall footprint, and enhances the precision of process control by allowing independent management of each fluid circuit.

Advanced Sealing Technology and Materials

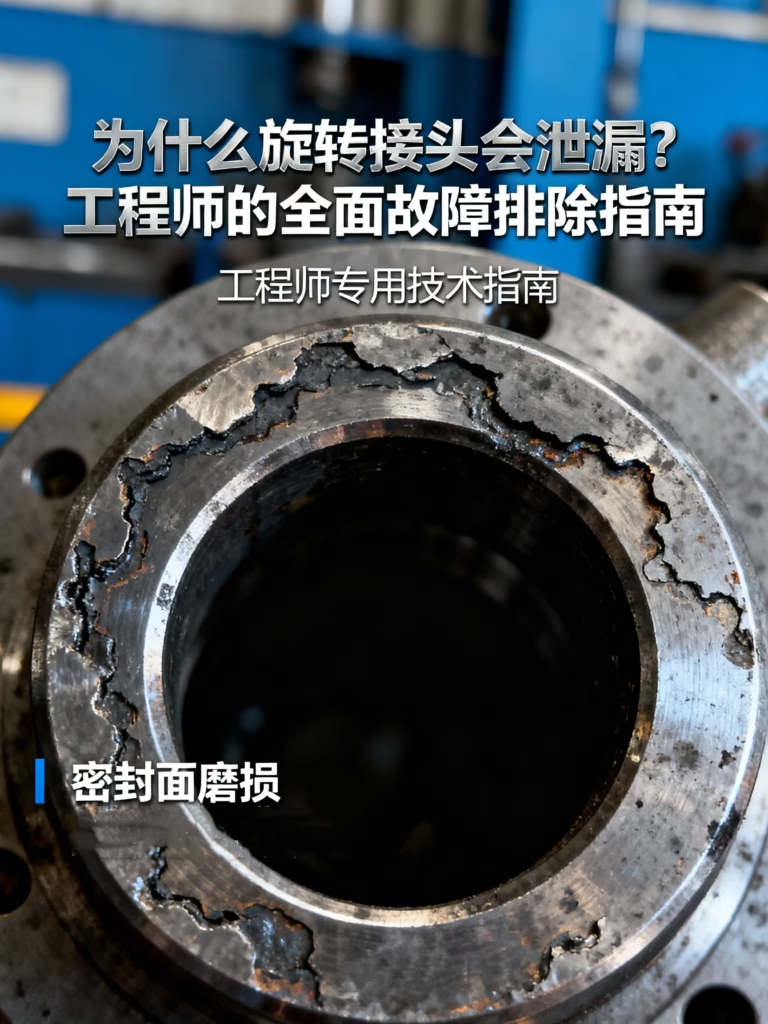

The seal is the most critical and technologically sophisticated part of the rotary joint. The choice of seal face materials is crucial for ensuring a long, leak-free service life in a high-temperature, high-pressure, and often abrasive environment. The goal is to create a pair of ultra-flat, lapped surfaces that rotate against each other, creating a near-perfect seal.

Spring-Compensated Structure: A spring mechanism (or sometimes a bellows) is used to apply a consistent axial force to the seal faces, keeping them in close contact even during minor axial movements or pressure fluctuations. This ensures the seal remains engaged and effective at all times.

High-Performance Materials: The seal faces are made from advanced materials selected for their unique combination of hardness, low friction, and thermal conductivity.

Below is a comparison of common seal face materials used in rotary joints for casting and rolling mills:

| Material Combination | Key Advantages | Best Suited For |

|---|---|---|

| Carbon-Graphite vs. Steel | Good self-lubricating properties, cost-effective. | Lower pressure and speed applications with clean fluids. |

| Carbon-Graphite vs. Ceramic | Excellent chemical resistance, good for water-based coolants. | General-purpose water and coolant service. |

| Silicon Carbide vs. Silicon Carbide (SiC/SiC) | Extreme hardness, excellent wear resistance, superior thermal conductivity to dissipate heat. | High-speed, high-pressure applications, and fluids with some abrasive particles. |

| Tungsten Carbide vs. Tungsten Carbide (WC/WC) | Highest toughness and impact resistance, excellent for handling shocks and abrasive media. | Heavy-duty applications with poor fluid quality or high potential for vibration. |

The selection of the right seal materials is a critical engineering decision that directly influences the rotary joint’s reliability and lifespan. Silicon carbide pairings have become a go-to choice for demanding rolling mill applications due to their exceptional balance of properties.

III. Practical Application and Performance Analysis

The theoretical advantages of a well-designed rotary joint translate into tangible benefits on the production floor. The performance of this single component can have a cascading effect on product quality, operational costs, and overall equipment effectiveness (OEE).

A Case Study: Enhancing an Aluminum Casting and Rolling Line

Consider an aluminum casting and rolling production line that was experiencing issues with inconsistent product quality and frequent maintenance downtime. We identified the primary problems as poor roll life and variations in the thickness of the final aluminum strip. An investigation revealed that the existing rotary joints were failing to provide consistent coolant flow, leading to thermal instability in the rolls.

After upgrading to a high-performance, multi-channel rotary joint with a Silicon Carbide (SiC/SiC) seal package and a precision bearing system, the plant observed dramatic improvements:

Improved Product Quality: The new joints provided a stable, high-volume flow of coolant, enabling precise thermal control of the rolls. This uniform cooling prevented internal stresses and shape defects in the aluminum strip. As a direct result, the plant was able to control the **product thickness variation to within ±0.02 mm**, a significant improvement that met the demands of their most exacting customers.

Extended Roll Life: The stable lubrication provided through the second channel of the rotary joint, combined with reduced operational vibration, drastically cut down on roll wear. The facility reported that the roll consumption was reduced by approximately 18%, leading to substantial savings in both replacement parts and the labor required to change them.

Reduced Unplanned Downtime: The robust design and advanced seal materials of the new rotary joints virtually eliminated the leaks and bearing failures that had plagued the old system. This led to a significant increase in machine uptime and production throughput, delivering a clear return on investment.

This example highlights how investing in superior rotary joint technology is not just an equipment upgrade; it’s a strategic move to enhance quality control and reduce operational expenditures.

IV. Future Development Trends and Outlook

The non-ferrous metal processing industry pushes towards higher speeds. It also aims for greater precision. Additionally, it focuses on smarter manufacturing. In response, the technology behind rotary joints evolves. This evolution happens in tandem with industry demands. Our future efforts will focus on intelligence, longevity, and efficiency.

Intelligent and “Smart” Rotary Joints

The next frontier is the integration of sensors and data connectivity, aligning with the principles of Industry 4.0.

Integrated Sensing: Future rotary joints will increasingly feature embedded sensors. These sensors will monitor critical parameters in real-time. The parameters include media temperature, pressure, and flow rate. They will also monitor vibrational signatures.

Predictive Maintenance: This data can be fed into a plant’s control system (PLC or DCS) to enable predictive maintenance. Instead of replacing joints on a fixed schedule, maintenance teams can now be proactive. They receive alerts when a seal shows early signs of wear. They also receive alerts when a bearing shows early signs of wear. This allows them to schedule a repair. As a result, they can prevent a catastrophic breakdown.

Closed-Loop Control: Real-time data on coolant flow and temperature enables a closed-loop control system. In this system, the mill can automatically adjust fluid delivery. This adjustment optimizes the casting process. Consequently, it improves product consistency. Additionally, it reduces energy waste.

Long-Term, Maintenance-Free Operation

Downtime is the enemy of productivity. The industry is continuously moving towards components that require less human intervention. This is being achieved through:

Advanced Materials: Research into new seal face materials and advanced coatings that offer even greater wear resistance and lower friction.

Sealed-for-Life Bearings: The use of high-quality, permanently lubricated bearings that eliminate the need for periodic greasing.

Cartridge-Based Design: Thanks to a modular, or cartridge-style, design, we can replace the entire sealing and bearing package as a single unit. This process takes only minutes, which drastically reduces the Mean Time To Repair (MTTR).

Conclusion

The rotary joint may be a relatively small component in a massive casting and rolling mill. However, it is undeniably a piece of core technology. In fact, it punches far above its weight. Moreover, it is the critical enabler of thermal management and lubrication systems. These systems are fundamental to producing high-quality nonferrous metals efficiently and reliably. If a high-performance rotary joint is not specified, it can compromise the entire operation. Consequently, this leads to quality defects. In addition, it causes costly downtime. Furthermore, it results in excessive maintenance burdens.

Materials science, sealing technology, and intelligent design continuously advance. As a result, the performance and capabilities of rotary joints improve. They provide vital technical support for the industry’s goals. These goals include energy conservation, consumption reduction, and quality improvement. Furthermore, as these components integrate more with intelligent control systems, their role expands. They will play a greater role in digitalization. Additionally, they advance smart-manufacturing transformation. Ultimately, this impacts casting and rolling technology worldwide.