How to build a swivel joint?

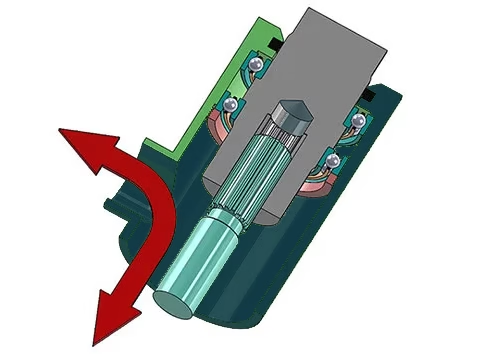

What is a swivel joint?

A swivel joint, also known as a rotary joint or rotary union, is a mechanical device that allows the transfer of fluids (such as liquids and gases) or even electrical signals between stationary and rotating parts in a system. In essence, it serves as a connection point that enables relative rotation while maintaining the integrity of the transfer. The key function of a swivel joint is to provide a leak-free and smooth connection, which is essential for the proper operation of various industrial and mechanical systems. It enables the seamless transfer of substances or signals, preventing disruptions and potential damage to the overall system.

Types of Swivel Joints

Mechanical Swivel Joints

These are the most basic types, mainly designed for mechanical movement and rotation. They are often used in applications where the transfer of torque or simple rotational motion is required.

Fluid-Transfer Swivel Joints

As the name implies, these are used for the transfer of fluids. They can handle a wide range of fluids, from water and oil to more specialized industrial chemicals. These joints are designed with seals to prevent fluid leakage and ensure efficient transfer. The seals are often made of materials that are compatible with the fluids being transferred, such as rubber for water-based fluids or fluorocarbon for more corrosive chemicals.

Electrical Swivel Joints

Also known as slip rings, electrical swivel joints are used to transmit electrical power and signals between stationary and rotating components. Electrical swivel joints typically consist of a set of conductive rings and brushes. The rings are attached to the rotating part, while the brushes are in contact with the rings and are connected to the stationary part, allowing for the transfer of electrical current or signals.

Understanding these basic concepts and types of swivel joints sets the foundation for the subsequent discussion on how to build one. The choice of type will greatly influence the construction process, the materials used, and the tools required.

Tools and MaterialsBuildingd a swivel joint requires a combination of specific tools and materials, each playing a crucial role in the construction process. Here is a comprehensive list to build a swivel joint:

1. Tools to build a swivel joint

1.1 Lathe

A lathe is an essential tool for machining the cylindrical parts of the swivel joint. It allows for the precise shaping and turning of materials such as metal rods. This ensures that the shaft rotates smoothly within the housing. The lathe can also be used to create threads on the shaft or housing if required for assembly purposes.

1.2 Milling Machine

Milling machines are used to create flat surfaces, slots, and complex shapes on the components of the swivel joint. They are particularly useful for machining the housing of the swivel joint, where features such as mounting holes or grooves for seals need to be created. A milling machine can provide high-precision cuts, ensuring that the components fit together accurately.

1.3 Drill Press

A drill press is needed to create holes in the various components of the swivel joint. Holes are required for purposes such as mounting the joint, inserting fasteners, or for the passage of fluids or electrical wires in some cases. The drill press allows for accurate drilling at the desired angles and depths.

1.4 Tap and Die Set

This set is used to create internal and external threads. In a swivel joint, threads are often used for connecting different components, such as attaching the housing to a pipe or fitting. The tap is used to create internal threads in a hole, while the die is used to create external threads on a rod or shaft.

1.5Measuring Tools

Vernier Caliper: A vernier caliper is used to measure the dimensions of the components accurately.

Micrometer: Micrometers are even more precise than vernier calipers and are used for measuring very small dimensions with high accuracy.

2. Materials to build a swivel joint

2.1 Metals

Stainless Steel: Stainless steel is a popular choice for swivel joints due to its corrosion resistance, high strength, and durability. It can withstand exposure to various fluids and environmental conditions without rusting.

Brass: Brass is another commonly used material, especially for swivel joints that are used in low-pressure fluid-transfer applications. It has good corrosion resistance, is easy to machine, and has excellent thermal conductivity.

Aluminum: Aluminum is lightweight and has good corrosion resistance. It is suitable for applications where weight is a critical factor, such as in aerospace or portable equipment.

2.2 Bearings

Bearings are essential components in a swivel joint as they enable smooth rotation. Here are 2 different types.

Ball Bearings: Ball bearings are widely used due to their low friction and ability to handle both radial and axial loads. They consist of a set of balls that are held between two racquets.

Roller Bearings: Roller bearings are better suited for applications that require higher load-carrying capacity. They use cylindrical or tapered rollers instead of balls. In an industrial-grade swivel joint that needs to support heavy loads during rotation, roller bearings would be a more appropriate choice.

3. Seals

Seals are crucial for preventing fluid leakage in a swivel joint. The type of seal used depends on the type of fluid being transferred, the operating pressure, and the temperature.

O-ring: O-rings are one of the most common types of seals. They are made of rubber or other elastomeric materials and are used to create a seal between two mating surfaces.

Mechanical Seals: Mechanical seals are more complex and are often used in high-pressure or high-temperature applications. They consist of a stationary and a rotating ring that are in contact with each other, creating a seal.

4. Fasteners

Fasteners such as bolts, nuts, and screws are used to assemble the different components of the swivel joint. The choice of fastener depends on the material of the components, the required strength of the connection.

5. Lubricants

Lubricants are used to reduce friction between the moving parts of the swivel joint, ensuring smooth rotation and extending the lifespan of the joint.

Having the right tools and materials is the first step towards successfully building a high-quality swivel joint.

Step-by-Step Guide to Build a Swivel Joint

Building a swivel joint requires a systematic approach to ensure that all components are fabricated accurately and assembled correctly. The following is a detailed step-by-step guide:

1. Preparation Work

Before starting the actual construction, thorough preparation is essential. This includes a careful inspection of all the materials and tools. Check the metals for any defects such as cracks, dents, or impurities. Ensure that the bearings are the correct size and type as per the design requirements. Measure the inner and outer diameters of the bearings using a vernier caliper or micrometer to confirm their compatibility with the other components.

Inspect the seals to make sure they are in good condition and free from any damage. O-rings, for instance, should be elastic and without any cuts or tears. If there are any doubts about the quality of the seals, it is advisable to replace them. Also, ensure that all the fasteners, such as bolts, nuts, and screws, are the right size and have the correct thread pitch.

On the tool side, make sure that the lathe, milling machine, and drill press are in proper working order. Check the cutting tools for wear and replace them if necessary. For a lathe, the cutting inserts should be sharp to ensure precise machining of the metal components. Calibrate all the measuring tools, such as the vernier caliper and micrometer, to ensure accurate measurements during the fabrication and assembly process. This calibration can be done using standard gauge blocks or by following the manufacturer’s instructions.

2. Component Fabrication

2.1 Making the Joint Housing

Start by using a lathe to machine the basic shape of the housing from a metal block, such as stainless steel or brass. If the housing is cylindrical, a lathe will be used to turn the outer diameter to the desired size with high precision.

Use a milling machine to create any additional features on the housing. This may include flat surfaces for mounting brackets, grooves for seals, or holes for bolts. For instance, if the swivel joint is to be mounted on a machine using bolts, the milling machine can be used to create bolt-hole patterns on the flat surface of the housing. The holes should be drilled perpendicular to the surface, and their positions should be accurately measured and marked before drilling.

2.2 Fabricating the Rotating Shaft

The rotating shaft is usually made from a metal rod. Use a lathe to machine the shaft to the required diameter and length. The diameter of the shaft should be such that it can fit smoothly inside the bearings and rotate with minimal friction.

Create threads on the shaft if it needs to be connected to other components, such as a coupling or a rotating part. A tap-and-die set can be used to cut the threads. The thread pitch and length should be consistent with the mating components.

If the shaft has keyways or slots for transmitting torque, these can be created using a milling machine. The keyways should be precisely machined to ensure a proper fit with the keys that will be used to couple the shaft to other rotating parts.

2.3 Manufacturing the Bearings Seats

The bearing seats are an important part of the swivel joint as they provide support for the bearings. These seats can be machined as integral parts of the housing or as separate components that are then attached to the housing.

If the bearing seats are integral to the housing, use the lathe to machine the inner diameter of the housing to the correct size to accommodate the bearings. The tolerance for the bearing seat diameter should be very tight, usually within ±0.02 mm, to ensure a secure fit for the bearings.

If the bearing seats are separate components, fabricate them from metal blocks using a combination of lathe and milling operations. The outer diameter of the bearing seat should match the inner diameter of the housing, and the inner diameter should be the same as the outer diameter of the bearings.

2.5 Creating the Sealing Surfaces

For fluid-transfer swivel joints, the sealing surfaces are crucial to prevent leakage. The sealing surfaces can be machined on the housing and the shaft.

Use a lathe to create smooth and flat surfaces on the shaft and the housing where the seals will be installed. The surface finish of these sealing surfaces should be very smooth, typically with a roughness value of less than 0.8 μm. This smooth surface ensures that the seals can make a tight contact and prevent fluid leakage.

If the seals are O – O-rings, create grooves in the housing and the shaft to accommodate the O-ring. The depth and width of the grooves should be designed according to the size of the O-ring to ensure a proper fit.

Assembly Process

3.1 Installing the Bearings

First, clean the bearing seats and the bearings thoroughly to remove any debris or dust. Apply a thin layer of lubricant, such as a high-quality grease, to the bearing seats.

Carefully place the bearings into the bearing seats. For ball bearings, ensure that the balls are evenly distributed and the bearing rotates freely. If the bearings are press-fit, use a suitable press or a hammer and a socket to gently install the bearings. Make sure not to damage the bearings during installation.

Once the bearings are installed, check the rotation of the shaft. The shaft should rotate smoothly with minimal resistance. If there is any binding or excessive friction, it may indicate that the bearings are not installed correctly or that there is some misalignment.

3.2 Placing the Seals

Insert the seals, such as O-rings, into the grooves on the shaft and the housing. Ensure that the seals are properly seated and there are no wrinkles or twists in the seals.

For mechanical seals, carefully assemble the stationary and rotating rings according to the manufacturer’s instructions. The mating surfaces of the mechanical seal rings should be clean and free from any scratches or debris. Apply a small amount of lubricant to the seal faces to ensure smooth operation.

3.3 Mounting the Rotating Shaft

Insert the rotating shaft into the bearings and through the housing. Make sure that the shaft is centered and aligned properly. If there are any keyways or splines on the shaft, align them with the corresponding features on the other components.

Secure the shaft in place using retaining rings, nuts, or other fastening methods as per the design. The retaining rings should be installed correctly to prevent the shaft from moving axially.

3.4 Connecting the Inlet and Outlet Ports (for fluid-transfer swivel joints)

If the swivel joint is for fluid transfer, attach the inlet and outlet ports to the housing. This may involve using threaded connections, flanges, or other types of fittings.

For threaded connections, apply a thread-sealing compound, such as Teflon tape or pipe dope, to ensure a leak-free connection. Tighten the fittings to the recommended torque using a torque wrench to avoid over-tightening or under-tightening.

If flanges are used, install gaskets between the flanges to create a seal. Bolt the flanges together evenly, tightening the bolts in a criss-cross pattern to ensure a uniform seal.

3.5 Final Inspection and Testing

After the assembly is complete, perform a final inspection of the swivel joint. Check all the connections, seals, and moving parts. Make sure that all the fasteners are tightened properly and there are no loose components.

For fluid-transfer swivel joints, conduct a leak test. Apply pressure to the inlet port and check for any signs of leakage at the seals, connections, or other parts of the joint. The pressure used for the leak test should be at least equal to the maximum operating pressure of the swivel joint.

For electrical swivel joints, perform a continuity test to ensure that the electrical connections are correct and there are no open circuits or short circuits. Use a multimeter to measure the resistance between the electrical terminals.

If the swivel joint is for a mechanical application, test its rotation by manually rotating the shaft or by using a motor to drive the rotation. Check for any abnormal noises, vibrations, or excessive friction during rotation.

By following these steps carefully, you can build a high-quality swivel joint that meets the required specifications and functions effectively in its intended application.

Conclusion

Building a swivel joint requires meticulous planning, precision machining, and rigorous testing to ensure reliable performance. While this guide provides a general overview, professional expertise is crucial for complex industrial applications.

If you’re looking to build a swivel joint for a specific application or require custom solutions, contact us directly.