Mechanical Seals, Rotary Joints, and Pumps: A Complete Guide for Industry Professionals

In the intricate world of industrial machinery, mechanical seals, rotary joint and pump. They play pivotal roles in ensuring the efficient transfer and containment of fluids. Whether in manufacturing plants, power generation facilities, or oil and gas operations. These components work in harmony to keep processes running smoothly. Understanding their functions, characteristics, and applications is crucial for engineers, maintenance professionals, and anyone involved in industrial operations. In this blog post, we will delve deep into the knowledge of mechanical seals, rotary joints, and pumps, exploring their significance and how they collaborate within fluid handling systems.

Mechanical Seals: The Guardians of Leak-Free Operations

What is a Mechanical Seal?

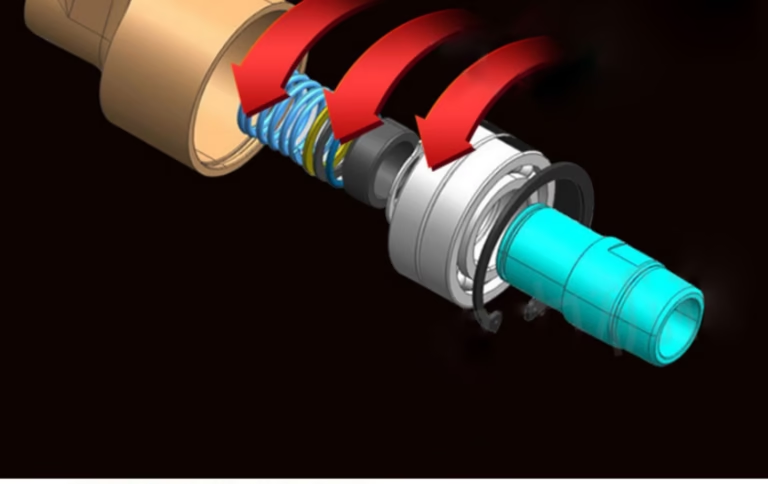

Engineers design a mechanical seal to prevent fluid leakage between two mating surfaces. Typically, between a rotating shaft and a stationary housing. It provides a reliable and efficient seal. Ensuring that the fluid within a system remains contained while allowing the shaft to rotate freely. Mechanical seals consist of several key components. Including a stationary seal face, a rotating seal face, a spring-loaded assembly, and a set of elastomeric O-rings or gaskets.

The stationary seal face is mounted on the housing, while the rotating seal face is attached to the shaft. The spring-loaded assembly applies pressure to the seal faces, ensuring that they remain in close contact with each other. This pressure creates a thin film of fluid between the seal faces, which acts as a lubricant and helps to reduce friction and wear. The elastomeric O-ring or gaskets provide additional sealing and prevent fluid from leaking around the periphery of the seal faces.

How Does a Mechanical Seal Work?

The operation of a mechanical seal is based on the principle of creating a tight seal between the rotating and stationary components while allowing for relative motion. As the shaft rotates, the rotating seal face moves against the stationary seal face, and the spring-loaded assembly maintains the necessary contact pressure. The thin film of fluid between the seal faces acts as a barrier, preventing the fluid from leaking out of the system. When the fluid pressure inside the system increases, it helps to press the seal faces together, enhancing the sealing effectiveness. Conversely, when the fluid pressure decreases, the spring-loaded assembly ensures that the seal faces remain in contact, preventing air or other contaminants from entering the system. The elastomeric O-ring or gaskets also play a crucial role in maintaining the seal by preventing fluid from leaking along the outer edges of the seal faces.

Types of Mechanical Seals

There are several types of mechanical seals available, each designed for specific applications and operating conditions. Some of the most common types include:

Single-Spring Mechanical Seals:

These seals use a single spring to apply pressure to the seal faces. They are relatively simple in design and are suitable for applications with moderate pressure and temperature requirements.

Multi-Spring Mechanical Seals:

As the name suggests, multi-spring mechanical seals use multiple springs to apply pressure to the seal faces. Engineers use this design to ensure more uniform pressure distribution. It suits applications requiring higher pressure and better sealing performance.

Cartridge Mechanical Seals:

Cartridge mechanical seals are pre-assembled units that can be easily installed and replaced. They come with all the necessary components, including the seal faces, springs, and O-rings, already assembled in a cartridge. This makes installation and maintenance quicker and more convenient, reducing downtime.

Double-Mechanical Seals:

Double-mechanical seals consist of two sets of seal faces, one inside the other. They are used in applications where a higher level of sealing is required, such as in hazardous or toxic fluid handling. The space between the two seal faces can be filled with a barrier fluid, which helps to prevent the leakage of the process fluid and also provides additional lubrication and cooling.

Applications of Mechanical Seals

Mechanical seals find widespread applications in various industries, including:

Oil and Gas:

In the oil and gas industry, mechanical seals are used in pumps, compressors, and other equipment to prevent the leakage of oil, gas, and other hydrocarbons. They are critical for ensuring the safety and environmental protection of oil and gas operations.

Chemical Processing:

Chemical plants rely on mechanical seals to contain a wide range of chemicals, including acids, alkalis, and solvents. These seals must be able to withstand the corrosive effects of these chemicals and maintain a reliable seal under high-pressure and high-temperature conditions.

Power Generation:

In power plants, mechanical seals are used in pumps, turbines, and other equipment to prevent the leakage of water, steam, and other fluids. They play a crucial role in ensuring the efficient operation of power generation systems.

Food and Beverage:

In the food and beverage industry, mechanical seals are used in pumps, mixers, and other equipment to prevent the contamination of food products. These seals must meet strict hygiene standards and be made from materials that are safe for use in food processing.

Rotary Joints: Enabling Fluid Transfer in Rotating Systems

What is a Rotary Joint?

A rotary joint, also known as a swivel joint or rotating union, is a mechanical device that allows the transfer of fluid (such as hydraulic oil, water, or air) between a stationary and a rotating component. It enables the continuous flow of fluid while the rotating component moves, which is essential in many industrial applications. Rotary joints typically consist of a stationary housing, a rotating shaft or rotor, seals, and bearings. The stationary housing is attached to the stationary part of the machine, while the rotating shaft or rotor is connected to the rotating component. The seals prevent the fluid from leaking out of the joint, and the bearings support the weight and rotational forces of the rotating component, ensuring smooth rotation.

How Does a Rotary Joint Work?

In a rotary joint, the fluid enters the stationary housing through an inlet port and then passes through the rotating shaft or rotor to the outlet port on the rotating component. As the rotating component turns, the rotary joint’s rotor rotates along with it, allowing the fluid to flow continuously. The seals inside the joint maintain a tight seal between the stationary and rotating parts, preventing fluid leakage. The design of the rotary joint’s seals is critical for its performance. Different types of seals, such as lip seals, mechanical face seals, or packing seals, can be used depending on the application requirements. For example, in high-pressure applications, mechanical face seals are often preferred due to their ability to provide a reliable seal under high-pressure conditions.

Types of Rotary Joints

There are several types of rotary joints available, each designed for specific applications and operating conditions. Some of the common types include:

Single-Passage Rotary Joints:

These joints have a single fluid passage and are used for applications where only one type of fluid needs to be transferred, such as in hydraulic systems.

Multi-Passage Rotary Joints:

Multi-passage rotary joints have multiple fluid passages, allowing the transfer of two or more different fluids simultaneously. They are commonly used in applications where complex fluid handling is required, such as in printing presses or textile machinery.

High-Pressure Rotary Joints:

High-pressure rotary joints are designed to withstand high-pressure fluid applications, typically in the range of several hundred to several thousand pounds per square inch (psi). They are used in industries such as oil and gas, where high-pressure fluid transfer is essential.

High-Temperature Rotary Joints:

High-temperature rotary joints are built to operate in applications with elevated temperatures, such as in power generation plants or foundries. They are made from materials that can withstand high temperatures without degrading, ensuring reliable performance.

Applications of Rotary Joints

Rotary joints are used in a wide variety of industries and applications, including:

Construction and Mining:

Manufacturers use rotary joints in construction and mining equipment—such as excavators, cranes, and drilling rigs—to transfer hydraulic fluid between the machines’ stationary and rotating parts. This allows the machines to perform various functions, such as lifting, digging, and rotating.

Manufacturing and Processing:

Manufacturers equip machines like injection molding machines, blow molding machines, and packaging equipment with rotary joints to enable fluid transfer between stationary and rotating components. They enable the transfer of fluids, such as cooling water, hydraulic oil, or air, to different parts of the machines, ensuring their proper operation.

Transportation:

Engineers install rotary joints in transportation vehicles like trucks, buses, and trains to transfer fluids such as fuel, oil, or air between stationary and moving parts, ensuring smooth and reliable operation.

Aerospace and Defense:

Engineers integrate rotary joints into aircraft, missiles, and other military equipment in the aerospace and defense industries to enable reliable fluid transfer between stationary and moving parts. They are critical for the transfer of fluids, such as fuel, hydraulic oil, or air, in these high-performance systems.

Pumps: The Heart of Fluid Movement

What is a Pump?

A pump is a mechanical device that moves fluids (liquids or gases) by converting mechanical energy into hydraulic energy. It creates a pressure difference that forces the fluid to flow from one point to another. Pumps are essential in many industrial processes, as they are responsible for transporting fluids such as water, oil, chemicals, and sewage. There are two main types of pumps: positive-displacement pumps and dynamic pumps. Positive-displacement pumps trap a fixed amount of fluid and force it out of the pump chamber. In contrast, dynamic pumps use a rotating impeller to increase the fluid’s velocity, which the pump then converts into pressure energy.

How Do Pumps Work?

Positive-Displacement Pumps

Positive-displacement pumps operate by repeatedly enclosing a volume of fluid and then displacing it. The most common types of positive-displacement pumps include gear pumps, piston pumps, and vane pumps.

Gear Pumps:

Gear pumps consist of two meshing gears that rotate within a housing. As the gears rotate, they create a series of chambers that trap and move the fluid from the inlet to the outlet. The meshing of the gears ensures a continuous flow of fluid.

Piston Pumps:

Piston pumps use one or more pistons that move back and forth within a cylinder. As the piston moves in one direction, it creates a vacuum that draws fluid into the cylinder. When the piston moves in the opposite direction, it forces the fluid out of the cylinder and into the discharge line.

Vane Pumps:

Vane pumps have a rotor with slots that contain vanes. As the rotor rotates, the vanes slide in and out of the slots, creating chambers that trap and move the fluid. The vanes are usually spring-loaded or rely on centrifugal force to maintain contact with the housing, ensuring a tight seal.

Dynamic Pumps Dynamic pumps:

Engineers widely use centrifugal pumps as the most common type of pump across various industries. They work by using a rotating impeller to increase the velocity of the fluid. Manufacturers typically mount the impeller on a shaft, which an electric motor or other power source drives to generate fluid flow. As the impeller rotates, it creates a centrifugal force that throws the fluid outward from the center of the impeller. The impeller increases the velocity of the fluid, and the pump then converts this velocity into pressure energy as the fluid flows into the diffuser or volute. The diffuser or volute gradually expands the flow area, reducing the velocity of the fluid and increasing the pressure.

Types of Pumps

In addition to the two main categories of positive-displacement and dynamic pumps, there are many subtypes of pumps available, each designed for specific applications and operating conditions. Some of the common types include:

Centrifugal Pumps:

As mentioned earlier, centrifugal pumps are the most widely used type of dynamic pump. They are available in various configurations, such as single-stage, multi-stage, horizontal, and vertical. Centrifugal pumps are suitable for a wide range of applications, from water supply and irrigation to chemical processing and power generation.

Reciprocating Pumps:

Reciprocating pumps are a type of positive-displacement pump that uses a piston or plunger to move the fluid. Engineers often use them in oil and gas production, chemical injection, and water treatment because they handle high pressure well.

Rotary Pumps:

Rotary pumps are another type of positive-displacement pump that uses rotating components, such as gears, lobes, or screws, to move the fluid. Engineers use them in applications that require a consistent flow rate and pressure, such as lubrication systems, food processing, and pharmaceutical manufacturing.

Diaphragm Pumps:

Diaphragm pumps use a flexible diaphragm to move the fluid. Engineers typically drive the diaphragm using a reciprocating or rotating mechanism to create the pumping action. They design diaphragm pumps to handle corrosive, abrasive, or highly viscous fluids effectively. By isolating the fluid from the pump’s moving parts, these pumps minimize wear and contamination, making them ideal for demanding chemical, wastewater, and industrial applications.

Applications of Pumps

Engineers use pumps in a wide range of applications across many industries, including:

Water Supply and Treatment:

Engineers and technicians use pumps to supply water to homes, commercial buildings, and industrial facilities. Additionally, operators rely on pumps in water treatment plants to move water efficiently through each stage of the process, including filtration, disinfection, and desalination.

Oil and Gas Industry:

In the oil and gas industry, engineers and operators use pumps for a wide range of critical operations. They pump crude oil directly from underground wells, transport oil and gas across vast distances through pipelines, and inject specialized chemicals into wells to enhance oil recovery and improve production efficiency.

Chemical Processing:

Chemical plants rely on pumps to transfer a wide range of chemicals, including raw materials, intermediate products, and finished products. Pumps must be able to handle corrosive, flammable, and toxic chemicals safely and efficiently.

Power Generation:

Operators in power plants use pumps to circulate water and steam through boiler systems, ensuring efficient heat exchange and pressure control. They also rely on pumps to move coolants through turbines to prevent overheating, and to deliver lubricating oils to engines and rotating machinery for smooth, uninterrupted performance. They are essential for the efficient operation of power generation systems.

The Synergy Between Mechanical Seals, Rotary Joints, and Pumps. Mechanical seals, rotary joints, and pumps do not operate in isolation. Instead, they work together in fluid handling systems to ensure the efficient transfer and containment of fluids. For example, in a hydraulic system, a pump is used to generate the pressure needed to move the hydraulic fluid. The fluid then travels through a series of pipes and hoses to a rotary joint, which allows the fluid to flow to the rotating parts of the machine, such as the hydraulic cylinders or motors. Engineers install mechanical seals at key points in the system—such as the pump shaft and rotary joint—to prevent hydraulic fluid from leaking. If any one of these components fails, it can have a significant impact on the overall performance of the fluid handling system.

Maintenance and Troubleshooting of Mechanical Seals, Rotary Joints, and Pumps

Maintenance

Mechanical Seals:

Regularly inspect mechanical seals for signs of wear, such as scratches, cracks, or uneven surfaces on the seal faces. Check the elastomeric O-rings or gaskets for signs of aging, swelling, or cracking. Lubricate the seal faces according to the manufacturer’s recommendations to reduce friction and wear. Replace any worn-out or damaged components promptly.

Rotary Joints:

Inspect rotary joints for fluid leaks, especially around the seals. Check the bearings for smooth rotation and any signs of excessive play or noise. Lubricate the bearings regularly to ensure their proper operation. Maintenance technicians should replace the seals promptly when they detect signs of wear or damage to prevent fluid leaks and equipment failure.

Pumps:

Monitor the performance of pumps, including flow rate, pressure, and power consumption. Check for any abnormal vibrations, noises, or leaks. Clean the pump inlet and outlet filters regularly to prevent clogging. Lubricate the pump bearings and other moving parts according to the manufacturer’s instructions. Replace any worn-out or damaged parts, such as impellers, seals, or bearings.

Troubleshooting

Mechanical Seals:

When a mechanical seal begins to leak, maintenance personnel should first inspect the installation to confirm that the seal is properly seated and securely tightened. They must also verify the alignment between the shaft and the seal housing, as misalignment can lead to uneven wear and leakage. If they find damage to the seal faces, they should promptly replace them to restore sealing integrity. In some cases, adverse fluid conditions—such as excessive temperature, high pressure, or corrosive media—may cause the leakage. Technicians must then implement appropriate corrective actions, such as adjusting operating parameters or selecting more suitable seal materials, to address these challenges.

Rotary Joints:

If a rotary joint is leaking, check the seals for wear or damage. Replace the seals if necessary. Check the alignment of the rotating shaft and the stationary housing. If the joint does not rotate smoothly, technicians should inspect the bearings, as wear or damage may be causing the issue. Replace the bearings if required.

Pumps:

If a pump is not producing the required flow rate or pressure, check the pump inlet and outlet valves to ensure that they are fully open. Check the pump impeller for damage or clogging. If the pump is vibrating excessively, check the alignment of the pump and the motor. Check the bearings for wear or damage. If the pump is making abnormal noises, it may be due to cavitation, which occurs when the fluid pressure drops below the vapor pressure of the fluid. Operators should properly prime the pump and maintain an adequate fluid level in the suction tank to prevent cavitation and ensure smooth, damage-free operation.

The Future of Mechanical Seal, Rotary Joint, and Pump

As technology continues to advance, the future of mechanical seals, rotary joint and pump looks promising. There is a growing trend towards the development of more advanced and intelligent components that can improve the efficiency, reliability, and performance of fluid handling systems. For mechanical seals, researchers are working on developing new materials and designs that can withstand more extreme operating conditions, such as higher temperatures, pressures, and corrosive environments.

Conclusion

A profound understanding of mechanical seal, rotary joint and pumps is of great significance for the safe and efficient operation of industrial production, as well as for equipment maintenance and management. Whether you are an engineer, technician, or equipment manager, continuous learning and mastery of this knowledge are essential to adapt to industry development and technological progress and ensure the stable and reliable operation of fluid handling systems.