SOLUTION

PULP & PAPER INDUSTRY

In the pulp and paper industry, rotary unions are crucial for connecting stationary steam and water supply lines to rotating equipment, such as drying cylinders and press rolls. They facilitate the transfer of steam for heating and cooling processes, essential for effective moisture removal from paper sheets during production. By allowing steam to enter the drying cylinders and enabling condensate to exit, rotary unions enhance energy efficiency and maintain optimal temperatures, ensuring high-quality paper production while minimizing leaks and downtime.

TEXTILE INDUSTRY

In the textile industry, rotary unions are crucial for transferring hot water or steam to rollers and dyeing machines. They ensure uniform heat treatment of fabrics during processes such as dyeing, finishing, and drying. By facilitating the efficient flow of heating media, rotary unions help maintain consistent temperatures, which is essential for achieving high-quality textile products while minimizing energy consumption and preventing leaks. Their reliable performance in demanding environments makes them integral to modern textile manufacturing processes.

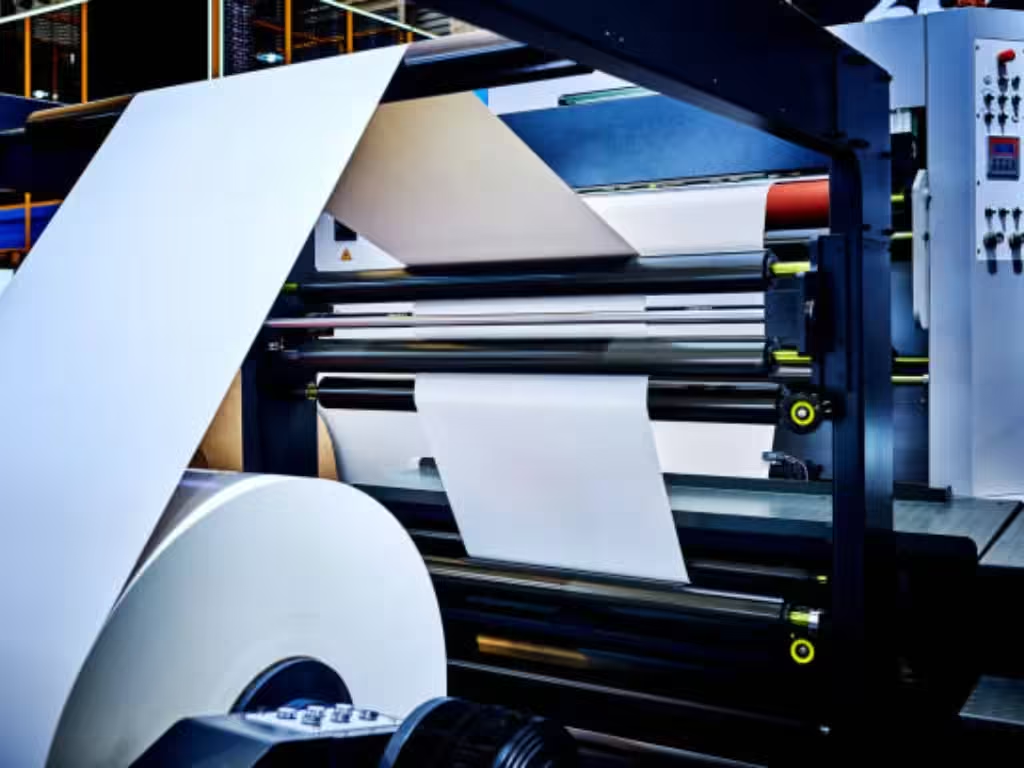

PRINTING INDUSTRY

In the printing industry, rotary unions are essential for transferring inks and cooling fluids to rotating components of printing presses. They facilitate the continuous flow of ink and other materials, ensuring consistent print quality while preventing leaks. Used in various printing methods, such as flexographic and gravure printing, rotary unions help maintain optimal temperatures for ink application and drying processes. Their reliable performance in high-speed operations is crucial for achieving high-quality prints and minimizing downtime during production.

CORRUGATORS MACHINES

In corrugator machines, rotary unions are essential for transferring steam and hot water to preheater rolls and drying sections. They enable the efficient heating of paper sheets during the corrugation process, ensuring proper adhesion and structural integrity. By allowing a continuous flow of heating media while preventing leaks, rotary unions enhance operational efficiency and product quality. Their robust design accommodates the high pressures and temperatures typical in corrugating operations, making them vital for maintaining consistent performance and minimizing downtime in production.

OIL & GAS INDUSTRY

In the oil and gas industry, rotary unions are crucial for transferring fluids such as oil, gas, and chemicals between stationary and rotating equipment. They are used in applications like drilling rigs and subsea systems, enabling efficient flow of hydraulic fluids and cooling media while withstanding high pressures and temperatures. Rotary unions facilitate operations such as wellbore cleaning and acidizing stimulation, ensuring reliable performance in demanding environments. Their ability to integrate with electrical slip rings further enhances functionality, making them vital for optimizing production and safety in oil and gas operations.

IRON & STEEL INDUSTRY

In the iron and steel industry, rotary unions are essential for cooling processes, particularly in continuous casting operations. They facilitate the transfer of water from stationary supply lines to rotating rolls that cool hot steel as it passes through. This ensures effective temperature control, preventing overheating and maintaining the integrity of the steel. Additionally, rotary unions are used in withdrawal and straightening units, allowing for efficient cooling while minimizing leaks and maintaining high operational efficiency in demanding environments.

RUBBER & TYPE

In the rubber and tire industry, rotary unions are crucial for facilitating the transfer of fluids such as water, oil, and steam in mixing and extrusion processes. They connect stationary supply lines to rotating machinery, ensuring a continuous flow of materials needed for rubber processing. By maintaining optimal temperatures and pressures during production, rotary unions enhance the efficiency of operations like vulcanization and molding. Their reliable performance in demanding environments helps minimize downtime and ensures high-quality rubber products.

FOOD INDUSTRY

In the food industry, rotary unions are essential for transferring steam, hot water, and other fluids to rotating equipment like mixers, blenders, and dryers. They ensure efficient heating and cooling during processes such as cooking, pasteurization, and drying, which are critical for food safety and quality. By allowing continuous fluid flow without leaks, rotary unions enhance operational efficiency in applications like bottling and packaging. Their design accommodates high pressures and temperatures while meeting hygiene standards, making them vital for maintaining consistent production in food processing.