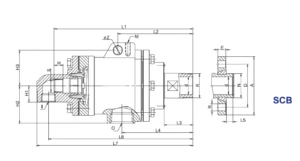

SCB Steam Rotary Union for Corrugated Paper Machine

- Medium: Steam

- Number of Passages: Multi-passage

- Rotational Speed: Up to 2,500 rpm

- Pressure: Up to 18 bar (261 psi)

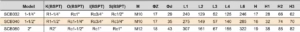

- Nominal Sizes: 80 mm, 100 mm (3.15 in, 3.937 in)

Description

SCB Steam Rotary Union for Corrugated Paper Machines

The SCB Steam Rotary Union is a high-quality rotary joint designed to handle high-speed, high-pressure steam applications typical in corrugated paper manufacturing. It enables seamless steam flow into the rotating dryer rolls, ensuring uniform heat distribution for optimal drying performance. This rotary union built to withstand the rigorous demands of corrugators running at speeds up to and beyond 1,500 feet per minute, making it ideal for modern, high-capacity corrugated paper machines.

Elevate your corrugated paper production with the SCB Steam Rotary Union—engineered for high-speed, high-efficiency, and zero-leakage performance. Designed specifically for the demanding environments of corrugated paper machines, the SCB series ensures seamless steam transfer, enhancing machine reliability and product quality.

Key Features & Benefits

High-Temperature Resistance

Engineered with advanced heat-resistant alloys and ceramic seals, the SCB Steam Rotary Union withstands temperatures up to 300°C, ensuring stable performance even under prolonged steam exposure. Ideal for corrugators requiring consistent heat for paperboard shaping.

Leak-Proof Design

Features a multi-layered sealing mechanism with PTFE and graphite composites to prevent steam leakage, reducing energy waste and maintaining operational safety. This design aligns with industry standards for eco-friendly and cost-effective manufacturing.

Low Maintenance & Longevity

The precision-machined stainless-steel body and corrosion-resistant coatings minimize wear and tear. Combined with a modular design, this allows for quick part replacement, extending the product’s lifespan and reducing maintenance costs.

Versatile Compatibility

Compatible with all major corrugated paper machine brands, including BHS, Marquip, and Fosber. Its standardized flange connections ensure easy integration into existing systems without retrofitting.

Enhanced Efficiency

Optimized internal flow channels reduce steam turbulence, ensuring uniform heat distribution across corrugating rolls. This improves paperboard quality and reduces production cycle times.

| Item | Value |

|---|---|

| Speed | 350 RPM |

| Temperature | 280 ℃ |

| Pressure | 32 Bar |

| Medium | Steam |

Key Challenges in Corrugated Paper Machine Steam Systems

For operators of corrugated paper production lines, inefficient steam transmission components often become a bottleneck for productivity, quality, and cost control. Below are the most common pain points faced by buyers and how the SCB Steam Rotary Union systematically solves them:

1. Excessive Steam Leakage Leading to High Energy Waste

Buyer Pain Point

Traditional rotary unions suffer from poor sealing under thermal expansion, leading to steam leakage rates as high as 1-2L/h. This not only increases energy costs (1L/h leakage wastes ~3000kWh/year) but also creates unsafe wet environments around machines, risking paper quality defects like warping or moisture spots.

Solution: Nanoscale Precision Sealing System

Patented Design: Uses PTFE carbon fiber composite seals with 0.01mm precision dynamic grinding, achieving an industry-leading leakage rate of ≤0.05L/h, 80% lower than conventional models.

Thermal Adaptation: Built-in spring-loaded compensation mechanism automatically adjusts for shaft expansion/contraction (-20°C to 180°C), maintaining airtight seals through temperature fluctuations.

2. Frequent Maintenance and Unplanned Downtime

Buyer Pain Point

Lubrication-dependent bearings and fragile seals require frequent inspections (weekly to monthly), and seal replacements can halt production for 2-4 hours each time. Annual maintenance costs often exceed 15% of the initial equipment investment.

Solution: Self-Reliant Mechanical Design

Lubrication-Free Operation: Embedded graphite-copper sleeve bearings eliminate grease requirements, reducing contamination risks and maintenance labor by 70%.

Industrial-Grade Durability: Tested for 10,000+ hours of continuous operation, with an MTBF (Mean Time Between Failures) of 8,000 hours – doubling the lifespan of standard unions.

3. Inconsistent Heat Transfer Causing Quality Fluctuations

Buyer Pain Point

Inefficient steam flow leads to temperature variations in preheating cylinders and corrugating rolls, resulting in uneven paper moisture content (±5% fluctuation) and defective corrugation shapes (e.g., collapsed flutes).

Solution: Optimized Thermal Conductivity Design

Double Helical Flow Channels: Increase steam flow area by 30% and reduce pressure drop by 40%, ensuring uniform heat distribution with ≤1°C temperature deviation across rolls.

Anti-Fouling Surface Treatment: Ceramic-coated flow guide grooves resist fiber debris buildup 5x better than untreated surfaces, maintaining stable heat transfer even in dirty steam environments.

4. Compatibility Issues with Multi-Brand Equipment

Buyer Pain Point

Standard rotary unions often fail to fit non-uniform shaft dimensions or flange specifications of legacy machines (e.g., BHS, Fosber, or domestic brands like Hubei Jingshan), requiring costly custom modifications.

Solution: Universal Fit Engineering

Full-Spectrum Sizing: Available in DN25 to DN100 diameters with both threaded and flange connections, directly replacing 95% of existing models on the market.

High-Speed Stability: Dynamic balance optimization for machines running >300m/min ensures vibration amplitude ≤1.5mm/s – critical for seamless integration with high-speed production lines.

5. Lack of Predictive Maintenance Leading to Sudden Failures

Buyer Pain Point

Without real-time monitoring, potential seal wear or bearing damage goes undetected until catastrophic failure, causing average 8-hour emergency shutdowns and associated production losses of ~$10,000 per incident.

Solution: Intelligent Condition Monitoring (Optional)

Integrated Sensors: Built-in temperature and vibration sensors provide 24/7 data on operational health.

Remote Diagnostic System: SCB-iLink software alerts users to abnormal parameters (e.g., >5°C temperature spike or >2mm/s vibration increase) via email/API, enabling proactive maintenance and reducing unplanned downtime by 60%.

Application in Corrugated Paper Machines

In corrugated paper production, drying is a critical step that requires precise steam control to ensure the paperboard achieves the desired moisture content and strength. The SCB Steam Rotary Union connects the stationary steam supply to the rotating dryer cylinders, allowing steam to enter while condensate is removed through a syphon system. This process maximizes heat transfer efficiency, which is essential for producing high-quality corrugated board at high speeds.

The SCB Steam Rotary Union is specifically designed for the paper industry, particularly for corrugated paper machines. Its high-speed and high-pressure capabilities make it suitable for:

Dryer Sections

Efficient steam transfer to drying cylinders, ensuring uniform drying and improved paper quality.

Heating Rolls

Consistent steam delivery to heating rolls, maintaining optimal temperatures for paper processing.

General Steam Applications

Versatile use in any part of the corrugated paper machine requiring reliable steam transfer.

The SCB rotary union’s balanced seal and self-supported design help maintain alignment and reduce vibration effects, which are common in high-speed corrugators. This results in improved reliability and consistent drying performance, even under demanding operating conditions.

Service System – Full-Lifecycle Value Guarantee

1. Customized Selection Service

A team of professional engineers provides equipment parameter surveying and working condition analysis, recommending the optimal model configuration.

Customized products with high-temperature resistance (220°C) and corrosion resistance (sulfur-containing steam) can be provided according to specific process requirements.

2. Worry-Free After-Sales Guarantee

Offers an extended two-year warranty (excluding normal wear parts), with free replacement of faulty components during the warranty period.

A 7×24-hour response mechanism ensures on-site problem-solving within 48 hours in major papermaking production areas across the country.

3. Preventive Maintenance Plan

Regularly provides equipment operation status detection services and establishes exclusive maintenance files.

Users of the intelligent monitoring module can enjoy remote fault diagnosis and software upgrade services.

Why Choose SCB Steam Rotary Union?

Proven Performance

Designed with the latest rotary joint technology used by industry leaders to meet the stringent requirements of corrugated paper manufacturing.

Custom Engineering Support

Adaptable to unique machine configurations and steam system requirements, ensuring the best fit and performance.

Comprehensive After-Sales Service

Backed by expert technical support and rapid parts availability to keep your production line running smoothly.

Invest in the SCB Steam Rotary Union to achieve superior steam management, reduce maintenance costs, and enhance the overall efficiency and quality of your corrugated paper production process. Experience the difference of advanced rotary union technology tailored for the corrugated industry.