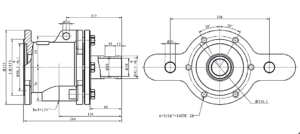

Q Type High Temperature Steam Corrugated Paper Machine Rotary Joint

Original price was: $50.00.$45.00Current price is: $45.00.

- Maximum Pressure: 1.8 MPa (18 bar)

- Maximum Temperature: 220 °C

- Maximum Speed: 150 RPM

- Materials: Cast Iron, Gray Iron, Ductile Iron, 45# Steel

- Seal Type: Q-Face Sealing Structure

Description

Product Overview of High Temperature Steam Rotary Joint

The Q Type High Temperature Steam Rotary Joint is a specialized rotary sealing device designed for the corrugated paper manufacturing industry and other demanding industrial applications. Engineered for reliable steam transfer at high temperatures and pressures, this rotary joint ensures efficient and leak-free steam delivery to rotating cylinders, which is critical for the corrugating process. The process adopts a balanced seal. According to the medium environment, different combinations of impregnated graphite, bronze, carbon tungsten, and silicon carbide are selected to resist the influence of rust, scaling, broken saltpeter, and other impurities on the sealing surface. The Joint is meticulously designed to meet the rigorous demands of modern corrugated paper production. Its robust construction and advanced sealing technology ensure efficient and reliable steam transfer, optimizing machine performance and product quality.

The Significance of Rotary Joints in Corrugated Paper Machines

Rotary joints play a crucial role in the functionality of corrugated paper machines. These specialized devices facilitate the transfer of various media between stationary and rotating components of the machine. By ensuring a leak-free and efficient connection, rotary joints enable the continuous flow of energy and materials, which is crucial for producing high-quality corrugated paper.

Without reliable rotary joints, corrugated paper machines would be prone to leaks, inefficiencies, and breakdowns, leading to costly downtime and reduced productivity. We engineer our rotary joints to withstand the demanding conditions of paper manufacturing, deliver long-lasting performance, and minimize maintenance requirements.

Key Features of High Temperature Steam Rotary Joint

Advanced Q-Face Sealing Structure

The unique Q-face seal design provides automatic centering and compensation, ensuring a tight, reliable seal even under low-speed conditions and slight misalignment. This results in minimal leakage and enhanced operational safety.

High Temperature and Pressure Capability

Supports steam pressures up to 1.8 MPa (approximately 18 bar) and temperatures reaching 220°C, making it ideal for high-temperature steam applications in corrugated board production.

Robust Material Construction

Manufactured from durable materials such as cast iron, gray iron, ductile iron, and 45# steel, the rotary joint withstands harsh industrial environments, ensuring longevity and resistance to wear.

No Lubrication Required

The design eliminates the need for external lubrication, reducing maintenance efforts and operational costs while enhancing reliability.

Self-Compensating and Self-Centering

The spring-loaded mechanism compensates for seal wear and axial movement, maintaining optimal sealing performance over extended service periods.

Suitable for Low-Speed and Low Coaxiality Equipment

Perfectly suited for corrugating machines operating at speeds up to 150 RPM, the joint accommodates slight shaft misalignments without compromising seal integrity.

| Item | Valve |

|---|---|

| Speed | 100-350 RPM |

| Temperature | 355 ℃/ 671 ℉ |

| Pressure | 18 Bar/260 Psi |

| Medium | Steam |

Pain Points of Steam Corrugated Paper Machine Rotary Joint

Pain Point 1: Sealing Failure

Under high-temperature and high-pressure steam environments, traditional seals are prone to aging, deformation, and leakage. Leakage not only causes steam waste but also affects the normal operation of the corrugated paper machine, resulting in production interruptions and increased maintenance costs.

Solution 1: Advanced Sealing Technology

Adopt high-performance sealing materials such as graphite-filled PTFE or special composite materials with excellent high-temperature and wear resistance. These materials can maintain good sealing performance under high-temperature and high-pressure steam conditions, reducing the risk of leakage and extending the seal’s service life. In addition, use double-seal or multi-seal structures to enhance the sealing effect further.

Pain Point 2: Corrosion and Wear

High-temperature steam contains certain impurities and moisture, which can cause serious corrosion and wear to the rotary joint materials. This reduces the service life of the rotary joint, requires frequent replacement, and increases equipment operation costs.

Solution 2:Material Upgrade

Use high-quality stainless steel or special alloy materials with excellent corrosion-resistance and wear-resistance for the rotary joint body and key components. Coat the internal surface of the joint with anti-corrosion and wear-resistant coatings, such as ceramic coatings or nickel-based alloy coatings, to improve the corrosion and wear resistance of the joint and extend its service life.

Pain Point 3: High Energy Consumption

Inefficient heat transfer and steam leakage lead to high energy consumption. The machine needs to consume more steam to maintain the required temperature, increasing production costs and hurting the environment.

Solution 3: Energy-Saving Design

Optimize the internal structure of the rotary joint to improve heat transfer efficiency and reduce steam leakage. Install heat-insulation layers on the outer surface of the rotary joint to minimize heat loss. Use energy-efficient steam control systems to precisely regulate steam flow and pressure, reducing unnecessary steam consumption.

Pain Point 4: Poor Rotational Stability

During the high-speed rotation of the corrugated paper machine, the rotary joint may experience vibration and instability, which can damage the internal structure of the joint, reduce its sealing performance, and affect the quality of corrugated paper production.

Solution 4: Enhanced Rotational Stability

Install high-precision bearings and balance the rotary joint during the manufacturing process to ensure stable rotation at high speeds. Use vibration-damping and shock-absorbing devices to reduce the impact of vibration on the rotary joint, improving its operational stability and protecting the internal structure of the joint.

Pain Points 5: Difficult Installation and Maintenance

The complex structure of the rotary joint makes installation and maintenance time-consuming and labor-intensive. Specialized tools and technical personnel often extend maintenance time and reduce production efficiency.

Solution 5: Simplified Design for Easy Installation and Maintenance

Redesign the structure of the rotary joint to make it more modular and user-friendly. Provide detailed installation and maintenance manuals and online video tutorials to help users install and maintain the rotary joint more easily. Develop quick-release and easy-replaceable components to reduce maintenance time and labor costs, minimizing production downtime.

Application of Q Type High Temperature Steam Corrugated Paper Machine Rotary Joint

The Q Type High Temperature Steam Rotary Joint is specifically engineered for high-speed, high-temperature environments commonly found in corrugated paperboard production lines. It plays a critical role in the heat transfer systems that drive the drying and shaping process of corrugated paper, ensuring operational efficiency, energy savings, and superior product quality.

1. Corrugated Paper Drying Cylinder Steam Transfer

In the single-facer and double-facer sections of a corrugated paper machine, steam-heated drying cylinders are used to bond and dry the paper layers. The Q Type rotary joint provides a rotating, leak-free connection that delivers high-temperature steam from a stationary pipeline into the spinning dryer rolls.

Function: Transfers saturated steam into the rotating drum

Operating conditions: Steam temperatures up to 180–220°C

Impact: Ensures uniform heat distribution for consistent bonding and drying of paper layers

2. Condensate Removal through Siphon System

The Q Type joint works in combination with stationary or rotary siphon systems to efficiently remove condensate from inside the heated rollers. Proper condensate drainage prevents water pooling, which can lead to uneven temperature distribution, paper defects, or cylinder damage.

Dual passage function: One port for steam in, one for condensate out

Benefit: Enhances thermal efficiency and reduces steam waste

3. Continuous High-Speed Rotation at Elevated Temperatures

Corrugated machines operate at high speeds, with dryer rolls rotating continuously under high thermal loads. The Q Type joint is built with self-supporting bearings, carbon graphite sealing rings, and corrosion-resistant housings that can withstand:

High RPM and axial movement

Extreme heat cycles

Steam pressure fluctuations

This makes the Q Type ideal for continuous-duty operations in demanding paperboard production environments.

Conclusion

In conclusion, our corrugated paper machine rotary joints are a reliable and efficient solution for the paper manufacturing industry. With their advanced sealing technology, high-quality materials, precision engineering, customization options, and easy installation and maintenance, our rotary joints offer several benefits that can help to improve the performance and productivity of your corrugated paper machines.

If you’re looking for a high-quality rotary joint for your corrugated paper machine, look no further. Contact us today to learn more about our products and services and to request a quote. We look forward to working with you!