What is the purpose of Rotary Joints for steam?

Unveiling the Purpose of Rotary Joints for Steam: A Comprehensive Guide

In the intricate world of industrial processes, steam plays a crucial role. From power generation to manufacturing, steam systems are the lifeblood of many industries. But have you ever wondered how steam travels efficiently in systems that involve rotary joints for steam? Enter the rotary joint—a seemingly small but incredibly important component. In this blog post, we’ll dive deep into the purpose of a rotary joint for steam, exploring its functionality, applications, and the benefits it brings to various industries.

Understanding the Basics: What is a Rotary Joint?

A rotary joint, also known as a swivel joint, is a mechanical device that enables the transfer of fluids, such as steam, air, water, or hydraulic oil, between stationary and rotating components in a system. In the context of steam, the rotary joint serves as a connection point that allows steam to flow into and out of rotating equipment while maintaining a secure and leak-free seal.

At its core, a rotary joint consists of several key components. The stationary housing, often made of durable materials like stainless steel or cast iron, provides a stable base. Inside the housing, there is a rotating shaft that connects to the rotating machinery. Seals, which are typically made of high-temperature-resistant materials such as graphite or PTFE (polytetrafluoroethylene), are used to prevent fluid leakage between the stationary and rotating parts. Bearings support the rotating shaft, ensuring smooth rotation and minimizing friction.

The Primary Purposes of a Rotary Joint for Steam

1. Facilitating the Transfer of Steam in Rotating Equipment

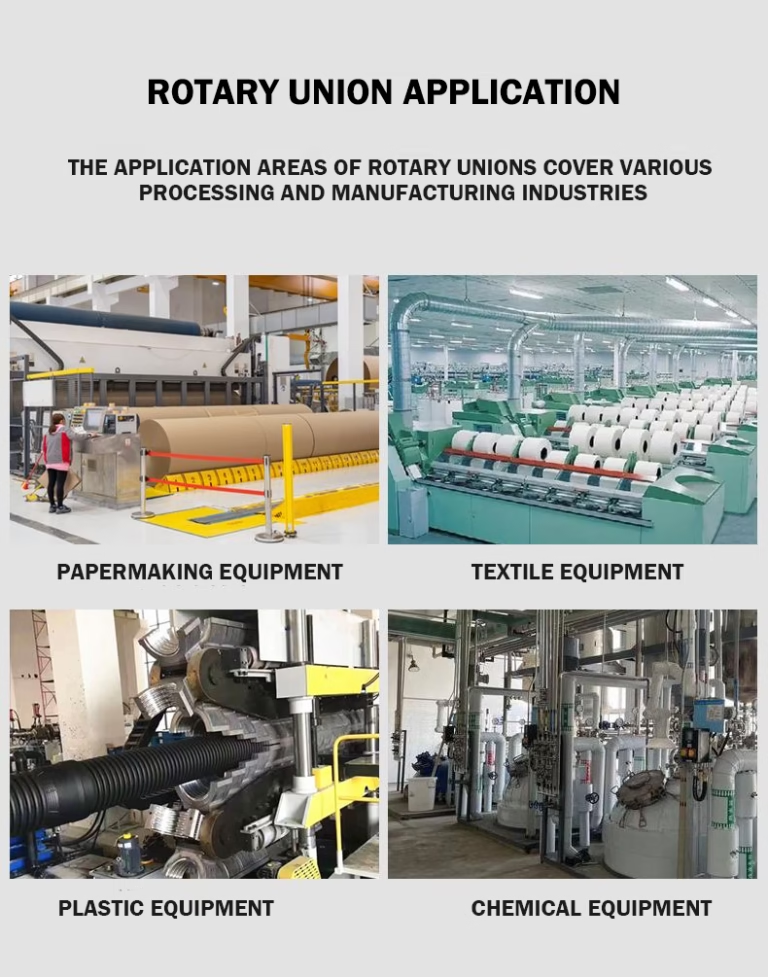

One of the main purposes of a steam rotary joint is to enable the seamless transfer of steam into and out of rotating machinery. Consider industrial dryers, which are commonly used in the paper, textile, and food industries. These dryers have large rotating cylinders that need to be heated with steam to dry the materials passing through them. Without a rotary joint, it would be impossible to supply steam to the rotating cylinder while it is in motion.

The rotary joint allows steam to enter the rotating cylinder through the stationary housing and then be distributed evenly throughout the cylinder. As the steam condenses inside the cylinder, the rotary joint also enables the removal of the condensed water, or condensate, back to the steam system for proper treatment and reuse. This continuous flow of steam and removal of condensate is essential for maintaining the efficiency and effectiveness of the drying process.

2. Maintaining a Secure Seal

Another critical purpose of a steam rotary joint is to maintain a secure seal between the stationary and rotating components. Steam systems operate under high-pressure and temperature conditions, and any leakage can lead to significant energy losses, reduced system performance, and even safety hazards.

The seals in a rotary joint should withstand these harsh conditions. They create a tight barrier that prevents steam from escaping and contaminants from entering the system. High-quality seals should have a long lifespan, even under continuous rotation and exposure to high-temperature steam. Regular maintenance and inspection of the seals are crucial to ensure their integrity and prevent leakage.

3. Reducing Friction and Wear

Rotating machinery in steam systems is constantly in motion, and friction between the moving parts can cause wear and tear over time. A rotary joint minimizes this friction. The bearings within the rotary joint support the rotating shaft, allowing it to turn smoothly with minimal resistance.

By reducing friction, the rotary joint not only extends the lifespan of the rotating equipment but also improves its overall efficiency. Less friction means less energy is required to operate the machinery, resulting in cost savings and reduced maintenance requirements. Additionally, reduced wear on the components leads to fewer breakdowns and less downtime for the steam system.

4. Enabling Precise Control of Steam Flow

In many industrial applications, precise control of steam flow is essential. A rotary joint can include additional components, such as flow control valves or pressure regulators, to allow for the accurate regulation of the steam entering and exiting the rotating equipment.

For example, in a chemical processing plant, the steam in a reaction vessel may need to be carefully controlled to ensure the correct chemical reactions occur. The rotary joint, along with the appropriate control devices, enables operators to adjust the steam flow rate, pressure, and temperature as needed, ensuring consistent product quality and process efficiency.

Applications of Steam Rotary Joints

1. Paper and Pulp Industry

In the paper and pulp industry, steam rotary joints are used extensively in paper machines. These machines consist of large rotating cylinders that are used for drying and pressing the paper. The steam rotary joints supply steam to these cylinders, which helps in removing moisture from the paper and giving it the desired texture and strength.

The high-speed rotation of the paper machine cylinders requires a reliable rotary joint that can handle the continuous flow of steam and the removal of condensate. Any leakage or malfunction of the rotary joint can lead to defects in the paper, such as uneven drying or wrinkles, resulting in significant production losses.

2. Textile Industry

Textile manufacturing involves various processes, including drying, steaming, and finishing. Steam rotary joints are used in textile dryers, which are used to dry fabrics after washing or dyeing. The rotary joints ensure that steam is evenly distributed throughout the dryer, allowing for efficient and consistent drying of the textiles.

In addition, steam rotary joints for textile finishing machines, such as calenders, to make smooth and polish the fabric. The steam helps in softening the fibers and improving the appearance of the fabric. The ability of the rotary joint to maintain a secure seal and precise control of steam flow is crucial in achieving high-quality textile products.

3. Food and Beverage Industry

In the food and beverage industry, steam has various purposes, including cooking, sterilization, and drying. Steam rotary joints are used in equipment such as rotary cookers, which for cook large quantities of food. The rotary joints supply steam to the cooker, ensuring even cooking and preventing contamination.

Steam rotary joints are also for food packaging machines, where steam for heat-sealing the packaging materials. The precise control of steam flow provided by the rotary joint is essential for ensuring a secure seal and maintaining the freshness and quality of the food products.

4. Power Generation

In power plants, steam rotary joints are used in turbines and other rotating equipment. Steam is generated in boilers and then used to drive the turbines, which generate electricity. The rotary joints allow steam to enter the turbines while they are in motion, enabling the efficient conversion of thermal energy into mechanical energy.

The high-pressure and high-temperature conditions in power plants require rotary joints that are highly reliable and durable. Any failure of the rotary joint can lead to a disruption in power generation, resulting in significant economic losses and potential power outages.

Benefits of Using Steam Rotary Joints

1. Energy Efficiency

By ensuring a secure seal and efficient transfer of steam, rotary joints help to minimize energy losses in steam systems. Leakage of steam can result in a significant waste of energy, as the steam that escapes is no longer available for use in the process. Rotary joints prevent this leakage, allowing for more efficient use of steam and reducing the overall energy consumption of the system.

In addition, the ability of rotary joints to reduce friction and wear in rotating equipment also contributes to energy efficiency. Less friction means less energy is required to operate the machinery, resulting in lower energy costs for the facility.

2. Improved Product Quality

Precise control of steam flow, temperature, and pressure provided by rotary joints is essential for maintaining consistent product quality in many industries. In the paper and textile industries, for example, even distribution of steam ensures that the materials are processed evenly, resulting in high-quality products.

In the food and beverage industry, accurate control of steam helps in maintaining the correct cooking and sterilization conditions, ensuring the safety and quality of the food products. Any variation in steam flow or temperature can lead to defects in the products, such as undercooked or overcooked food, or inconsistent texture in paper and textiles.

3. Increased Equipment Lifespan

The reduction in friction and wear provided by rotary joints extends the lifespan of the rotating equipment in steam systems. By minimizing the stress on the components, rotary joints help to prevent premature wear and tear, reducing the frequency of component replacements and maintenance.

This not only saves on maintenance costs but also reduces downtime for the equipment. In industrial settings, where every minute of downtime can result in significant production losses, the extended lifespan of the equipment provided by rotary joints is a major advantage.

4. Enhanced Safety

A secure seal provided by rotary joints is crucial for maintaining the safety of steam systems. Leakage of steam can pose a significant safety hazard, as high-pressure steam can cause burns and other injuries. Rotary joints prevent this leakage, ensuring the safety of the workers and the surrounding environment.

In addition, the ability of rotary joints to handle high-pressure and high-temperature steam reduces the risk of system failures, which can also lead to safety hazards. By maintaining the integrity of the steam system, rotary joints contribute to a safer working environment in industrial facilities.

Choosing the Right Steam Rotary Joint

When choosing a steam rotary joint, several factors need to be considered. The operating pressure and temperature of the steam system are crucial parameters. The rotary joint must be able to withstand the maximum pressure and temperature that the system will encounter during operation.

The flow rate of steam also needs to be taken into account. The rotary joint should be sized appropriately to handle the required steam flow without causing any restrictions or pressure drops. The type of rotating equipment and the speed of rotation are also important factors. Different rotary joints are designed for different types of machinery and rotational speeds.

The quality of the seals and bearings is another critical consideration. High-quality seals and bearings will ensure a long lifespan and reliable performance of the rotary joint. Additionally, the ease of maintenance and availability of spare parts should also be considered when choosing a steam rotary joint.

Maintenance and Troubleshooting of Steam Rotary Joints

Regular maintenance is essential to ensure the proper functioning of steam rotary joints. This includes inspecting the seals for signs of wear or damage, checking the bearings for smooth rotation, and lubricating the moving parts as required.

If a leakage occurs, it is important to identify the source of the problem quickly. Leakage can be caused by worn-out seals, damaged bearings, or improper installation of the rotary joint. Once the source of the leakage is identified, the appropriate repair or replacement measures can be taken.

In some cases, the rotary joint may experience excessive friction or vibration. This can be due to misalignment of the rotating shaft, worn-out bearings, or debris in the system.

Even the best rotary joints demand care. Follow this 5-step regimen:

Daily Inspection:

Check for steam leaks (listen for hissing, use infrared cameras).

Monitor bearing housing temperature (ideal: <80°C/176°F).

Weekly Lubrication:

Use high-temperature grease (NLGI #2) for bearings.

Avoid over-greasing—it attracts contaminants.

Monthly Seal Check:

Measure seal wear (replace at >0.8mm wear).

Clean carbon deposits with non-flammable solvents.

Annual Overhaul:

Replace all seals, bearings, and O-rings.

Conduct pressure testing (1.5x working pressure).

Water Treatment:

Install demineralized water systems to prevent scale buildup.

Scale reduces heat transfer efficiency by 15–20% annually.

Avoiding Costly Pitfalls – Common Mistakes and How to Sidestep Them

Even veterans make errors in rotary joint selection and operation. Guard against these:

Under-Sizing Joints:

60% of failures stem from inadequate flow capacity.

Use manufacturer sizing software—never guess.

Ignoring Steam Quality:

Wet steam (even 2% moisture) erodes seals 5x faster.

Install separators upstream of joints.

Mixing Media:

Never use steam joints for thermal oil or compressed air.

Cross-contamination risks, explosions, and void warranties.

Skipping Alignment:

Misalignment >0.1mm causes 70% premature bearing failures.

Use laser alignment tools during installation.

Conclusion

In conclusion, the purpose of a rotary joint for steam is multi-faceted and essential for the efficient operation of many industrial processes. From facilitating the transfer of steam in rotating equipment to maintaining a secure seal, reducing friction, and enabling precise control of steam flow, rotary joints play a vital role in steam systems.

Their applications span across various industries, including paper and pulp, textile, food and beverage, and power generation. The benefits of using steam rotary joints, such as energy efficiency, improved product quality, increased equipment lifespan, and enhanced safety, make them an indispensable component in industrial steam systems.

When choosing and maintaining a steam rotary joint, careful consideration of various factors is required to ensure its optimal performance. By understanding the purpose and functionality of steam rotary joints, industries can make informed decisions that will lead to more efficient, reliable, a