Trusted Deublin 1109-840-835 Rotary Union for Machine Tool Coolant

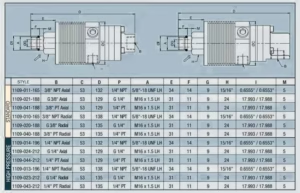

- Model Number: Deublin 1109-840-835

- Union Type: Monoflow Bearingless Rotary Union

- Rotor Connection: 3/4″ NPT, Right-Hand Thread

- Housing Connection: 1/4″ NPT

- Max. Coolant Pressure: 1,500 PSI (103 bar)

- Max. Speed: 10,000 RPM

- Max. Temperature: 250°F (120°C)

- Media Compatibility: Coolant, Cutting Fluid, MQL (Air/Oil Mist)

- Seal Face Combination: Silicon Carbide / Silicon Carbide (SiC/SiC)

- Housing Material: Anodized Aluminum

- Rotor Material: Hardened Steel

Description

The Deublin 1109-840-835 Rotary Union is a high-quality solution engineered for industries requiring reliable transfer of coolant, air, or other media between stationary and rotating equipment. Designed with precision and durability in mind, this rotary union provides smooth operation in demanding environments such as CNC machining, milling, drilling, and other high-speed industrial processes.

Our alternative to the original Deublin 1109-840-835 rotary union maintains comparable performance at a more cost-effective price point, making it an ideal choice for businesses seeking both efficiency and affordability. With features such as leak-resistant sealing, wear-resistant materials, and compatibility with multiple machine types, this rotary union ensures long-lasting performance while reducing operational downtime.

Whether you need a dependable rotary union for coolant supply, compressed air delivery, or lubrication transfer, this model delivers stable, precise, and consistent results.

Key Features of the Deublin 1109-840-835 Rotary Union

Single-Passage Design for Coolant or MQL

Engineered with a single-passage flow channel, this rotary union is optimized for either coolant delivery or Minimum Quantity Lubrication (MQL) applications. This ensures reliable media transfer with maximum efficiency, making it suitable for a wide range of CNC machining and high-speed milling operations.

Innovative “Pop-Off” Technology

The advanced Pop-Off seal system enables unlimited dry running without media pressure, eliminating the risk of seal damage when coolant flow is interrupted. This design improves reliability, reduces downtime, and extends service life—ideal for demanding production environments.

Full-Flow Internal Pathway

Featuring a full-flow design, the rotary union ensures there are no internal obstructions that could trap chips, swarf, or debris. This guarantees smooth, unrestricted coolant delivery to the cutting zone, enhancing machining accuracy and reducing the risk of clogging.

Bearing-Supported with Threaded Rotor

The precision bearing support system provides stability at high rotational speeds, while the threaded rotor design allows for quick and easy installation into machine spindles. This ensures reduced setup time and minimizes alignment issues during replacement.

Dual ABEC 7 (ISO Class P4) Angular Contact Bearings

Equipped with dual ABEC 7 precision ball bearings, this rotary union delivers exceptional rotational accuracy and long-lasting stability. The high-grade bearings minimize vibration, increase durability, and maintain precise alignment during high-speed operations.

Labyrinth System with Large Vents

To protect the internal ball bearings, the rotary union integrates a labyrinth sealing system and oversized vents. This configuration prevents contaminants such as coolant mist, dust, or chips from entering the bearing chamber, ensuring long-term reliability and reduced maintenance needs.

Balanced Silicon Carbide Mechanical Seals

The rotary union features balanced mechanical seals constructed from silicon carbide, a highly durable material known for its excellent wear resistance and thermal stability. Even under harsh conditions with fluctuating temperatures and pressures, the seals maintain a leak-free, reliable performance.

Corrosion-Resistant Aluminium Housing

The lightweight aluminium housing with an anodized endcap offers superior corrosion resistance while keeping the overall weight low. This contributes to easier handling during installation and provides long-lasting durability in coolant-rich environments.

Applications of Deublin 1109-840-835 Rotary Union

The Deublin 1109-840-835 Rotary Union finds applications across multiple industries:

-

CNC Machining & Milling Centers

Ensures continuous delivery of coolant to cutting tools, reducing tool wear and increasing machining precision. -

Automotive Industry

Used in high-speed production lines for reliable transfer of air, oil, and coolant, supporting seamless assembly operations. -

Aerospace Engineering

Provides precise fluid transfer required for advanced machining of aerospace-grade materials. -

Hydraulic and Pneumatic Systems

Transfers compressed air and hydraulic fluid reliably, supporting equipment performance under pressure. -

Industrial Manufacturing

Widely applied in drilling, grinding, and turning processes that demand leak-free and stable coolant flow.

Installation and Maintenance

Proper installation and system maintenance are critical to achieving the legendary longevity of a Deublin rotary union.

Immaculate Spindle Bore: The bearingless design relies on a clean, precise spindle bore for support. Before installation, thoroughly clean the bore to remove any rust, debris, or old sealant.

Anti-Rotation Pin: The housing must be kept from rotating with the spindle. Use a correctly sized anti-rotation pin or bracket that engages loosely with the housing, allowing for slight axial movement.

Flexible Hose Connection: Never use rigid plumbing for the housing connection. A flexible hose is mandatory to absorb any minor misalignment and prevent side-loading the union.

Critical Coolant Filtration: The SiC/SiC seals are tough but not invincible. Filter your coolant system to 25 microns or better. This protects the precision-lapped seal faces. This is the single most important factor in maximizing seal life.

Verify Concentricity: Ensure the machine spindle runs true. Excessive runout can lead to vibrations that will prematurely wear out the mechanical seals.

FAQ

Q1: What is the Deublin 1109-840-835 Rotary Union used for?

It is primarily used for transferring coolant, air, or other fluids between stationary and rotating components in machining and industrial systems.

Q2: Can this rotary union handle both coolant and compressed air?

Yes, it is designed for dual applications, ensuring versatility across various systems.

Q3: How does this compare to the original Deublin rotary union?

Our alternative matches the performance of the OEM version but comes at a more competitive price with faster availability.

Q4: What is the maximum speed this rotary union can handle?

It supports high-speed machining operations, ensuring smooth and stable coolant delivery.

Q5: Is it easy to install and maintain?

Yes, it features a user-friendly design that simplifies both installation and routine maintenance.

Conclusion

The Deublin 1109-840-835 Rotary Union is the perfect balance of performance, reliability, and cost-effectiveness. Whether you are managing CNC machining centers, automotive production lines, or aerospace manufacturing, this rotary union guarantees stable fluid transfer, reduced downtime, and lower operating costs.

By choosing this alternative, you gain access to premium performance at a fraction of the OEM price, along with the confidence that comes from using a trusted industrial solution.

Upgrade your equipment today with the Deublin 1109-840-835 Rotary Union alternative—engineered for precision, durability, and efficiency.