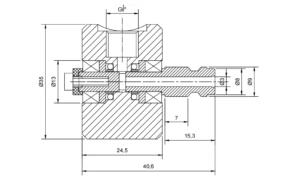

DN40-35.40 Aluminum Alloy Shell G1/8” Rotary Joint For Air

- Medium: Air

- Max. Temperature: 25℃

- Max. Pressure: 8 bar

- Max. Speed: 1500 rpm

- Stationary Port Thread Size: 1/8 “

Description

The Rotary Joint for Air is engineered for reliable, leak-free transmission of compressed air in rotating machinery. Built with lightweight aluminum alloy housing and a stainless steel rotating shaft, this rotary joint combines durability with efficiency, making it suitable for a wide range of industrial environments. Its advanced sealing technology prevents air leakage and ensures consistent performance, while precision craftsmanship minimizes vibration and wear, extending service life.

The body of our air rotary union is crafted from a high-grade aluminum alloy. This material was chosen for its ideal balance of lightweight design and superior strength. In applications where weight can impact the overall performance of a machine, such as on robotic arms or high-speed automation equipment, a lightweight component is a significant advantage. It reduces inertia, lowers energy consumption, and places less strain on the motor. Yet, despite its low weight, the aluminum alloy body is incredibly robust, capable of withstanding the rigors of industrial environments.

Whether you need a single-passage air rotary joint for standard pneumatic systems or a high-speed rotary joint for demanding production lines, this solution delivers excellent value at a competitive price point.

Key Features

High-Quality Materials

-

Aluminum Alloy Body: Provides a perfect balance of lightweight design and structural strength, reducing machine load while maintaining stability.

-

Stainless Steel Rotating Shaft: Resistant to wear, corrosion, and rust, ensuring reliable performance in high-humidity or dusty environments.

-

Long-Lasting Construction: Designed for both general-purpose and heavy-duty pneumatic applications.

Reliable Sealing Performance

-

High-Performance Seals: Engineered to withstand pressure fluctuations, ensuring no leakage of compressed air.

-

Stable Transmission: Keeps pneumatic systems running smoothly, preventing loss of efficiency.

-

Reduced Downtime: Leak-free design helps minimize maintenance requirements and operational disruptions.

Precision Craftsmanship

-

Strict Dimensional Control: Ensures excellent coaxiality and balanced rotation.

-

Low Vibration, Low Wear: Reduces friction and mechanical stress, extending the joint’s service life.

-

Consistent Output: Provides stable air delivery even under high-speed operation.

Great Value for Businesses

-

Competitive Pricing: Offers cost savings without compromising quality or performance.

-

Operational Efficiency: Achieve lower energy waste through efficient sealing and precision engineering.

-

Procurement Advantage: Ideal for manufacturers, OEMs, and system integrators seeking affordable air rotary unions.

Reliable Sealing: The Key to Stable Transmission

We integrate high-performance seals designed specifically for compressed air applications. These seals do not serve as a one-size-fits-all solution; instead, engineers design them with precision to create a tight, lasting barrier against air leakage. The materials chosen for our seals are resistant to wear and tear, and they maintain their elasticity and sealing properties over a wide range of temperatures and pressures.

This superior sealing mechanism provides three critical benefits for your operation:

- Stable Transmission: A leak-proof seal ensures that the system transmits compressed air at a consistent pressure and flow rate, which, in turn, is vital for the precise operation of pneumatic tools and actuators.

- Reduced Maintenance: By preventing leakage, our rotary air coupling significantly extends the time between maintenance checks. Fewer leaks mean less strain on your air compressor and fewer unexpected repairs.

- Minimized Downtime Risks: Leaking rotary joints are a primary cause of system failure and unscheduled downtime. Our reliable sealing system drastically reduces this risk, helping you maintain a smooth and efficient production schedule.

By choosing our air rotary union, you are investing in a product that actively contributes to the stability and reliability of your entire pneumatic system.

Why Choose Us? The Partner You Can Trust

We are not just a manufacturer; we are a partner in your success. Our commitment to quality, innovation, and customer satisfaction sets us apart. We have a deep understanding of the unique challenges faced by industrial businesses and have engineered our pneumatic rotary joints to meet and exceed those demands. By choosing us, you benefit from:

- Expert Support: Our team of technical experts is ready to assist you with product selection and application questions.

- Global Reach: We deliver reliable products to customers worldwide.

- Unwavering Quality: Our team rigorously tests every product to ensure it meets our high standards before it leaves our facility.

Ready to upgrade your pneumatic system’s performance and reliability?

Applications of Rotary Joint for Air

Industries widely apply the rotary joint for air wherever pneumatic power must be transmitted to rotating parts.

Robotics & Automation

Delivers compressed air to robotic arms for precise actuation.

Ensures smooth motion in high-speed automation lines.

Textile Machinery

Supplies air to spinning and weaving equipment.

Reduces downtime caused by leakage or seal failure.

Packaging Industry

Powers pneumatic cylinders in high-speed packaging machines.

Maintains efficiency during continuous operation.

Pneumatic Tools

Provides a reliable air supply to tools such as grinders, drills, and sanders.

Withstands repetitive motion and heavy workloads.

General Industrial Applications

Found in printing presses, conveyor systems, and assembly lines.

Supports energy-efficient compressed air delivery in rotary systems.

FAQ

Q: What is the main difference between a rotary joint for air and a standard swivel fitting?

A: A rotary joint is designed for continuous, high-speed rotation, while a standard swivel fitting is typically for low-speed or intermittent motion. The internal bearings and dynamic seals in a rotary union are built to handle the heat, friction, and wear from constant movement, ensuring a longer and more reliable service life.

Q: Can this rotary joint be used for other gases besides air?

A: Our standard air rotary joint is primarily designed and sealed for compressed air. For other gases, we recommend consulting with our technical team to ensure material and seal compatibility for your specific application.

Q: How do I know which size port to choose?

A: The port size should match the flow rate and pressure requirements of your pneumatic system. We provide detailed technical specifications to help you select the correct size. If you are unsure, our experts can provide guidance based on your application needs.

Q: How do I maintain this rotary joint?

A: Our air rotary unions are designed to be maintenance-free for their specified lifespan. However, it is essential to ensure that your air supply is clean and free of excessive moisture and contaminants to prevent premature wear on the internal seals and bearings.

Conclusion

The Rotary Joint for Air is a cost-effective, high-performance pneumatic rotary union designed for industrial reliability. With premium materials, advanced sealing, and precision engineering, it ensures leak-free air transmission, longer lifespan, and reduced downtime.

Whether for robotics, textile machines, packaging systems, or pneumatic tools, this rotary joint delivers outstanding value, helping businesses optimize performance and reduce operating costs.