HOW DOES A WATER ROTARY UNION WORK?

A water rotary union is an essential component in machinery where water needs to be transferred from a stationary source to a rotating part. Its primary function is to ensure that water can flow continuously and without leakage, even as the connected equipment rotates.A water rotary union operates by providing a seamless connection between a stationary fluid supply and a rotating component, allowing for the continuous flow of water or other fluids without leakage. Here’s a detailed breakdown of how it works:

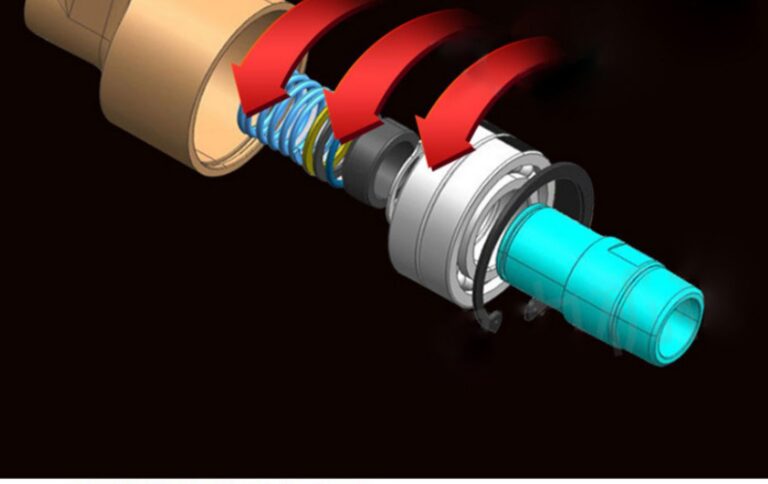

Key Components of water rotary union

Stationary Member: This part connects to the inlet pipes or hoses that supply the fluid.

Rotating Member: This part is attached to the rotating machinery or device.

Seals: These prevent fluid leakage and keep contaminants out.

Bearings: These facilitate smooth rotation of the internal components.

Functionality of water rotary union

The water rotary union connects a stationary inlet to a rotating outlet, maintaining a fluid connection while allowing for rotation. As the rotating part turns, the liquid flows into the union from its source and is held within the device during movement.

When the rotating component aligns with the outlet, the fluid exits the rotary union. This process repeats continuously as the component rotates, ensuring a steady flow of water or other fluids.

Types of Flow of water rotary union

Water rotary unions can be designed with different configurations:

Single-Flow Rotary Unions: Allow fluid to flow in one direction through a single passage.

Dual-Flow Rotary Unions: Feature two passages for simultaneous flow of different fluids, preventing cross-contamination.

Multi-Channel Rotary Unions: Handle multiple fluid types or channels concurrently, useful for complex applications.

Performance Characteristics of water rotary union

Pressure and Temperature Ratings: Water rotary unions are engineered to withstand various pressures (up to 20,000 PSI or more) and temperatures (from -150°F to +400°F), depending on application requirements.

Rotational Speed: They can operate at speeds ranging from 0 to over 10,000 RPM, making them suitable for both low-speed and high-speed applications.

In summary, water rotary unions are crucial for maintaining fluid transfer in systems where components rotate, ensuring efficiency and reliability across various industrial applications.