360 Degree Tower Crane Spray Universal Rotary Joint

Original price was: $35.00.$32.00Current price is: $32.00.

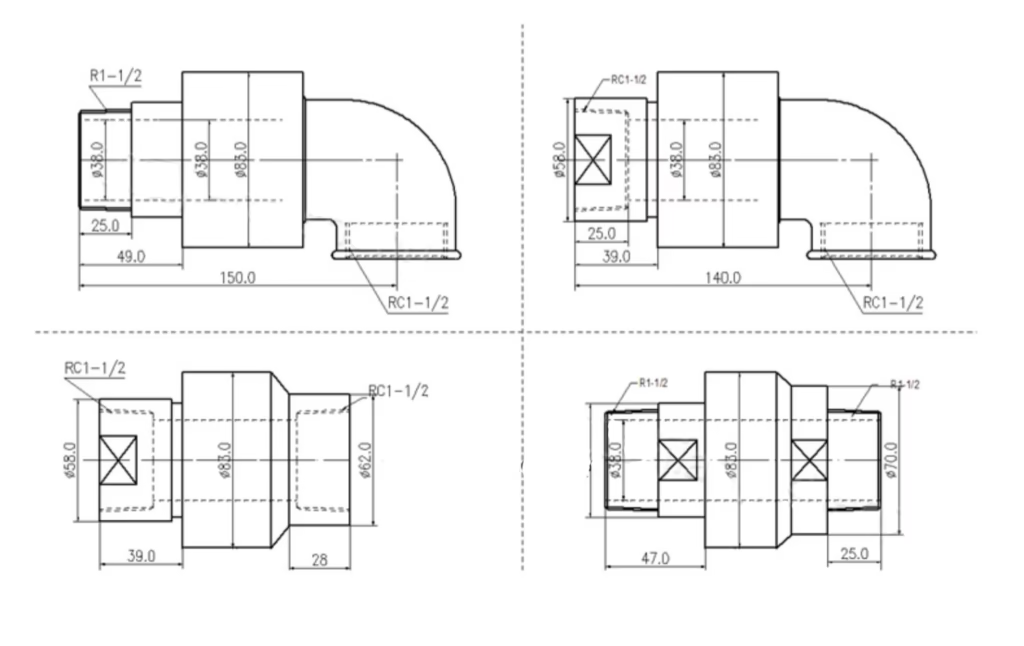

- Product name: High pressure rotary joint

- Size: Customized Size

- Max.Speed: 10-300RPM

- Max. Pressure: 0-35MPA

- Max. Temperature: 40-400ºC

- Medium: Steam, oil, water, air, oxygen, hydrogen, etc

Description

Product details

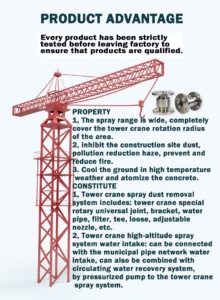

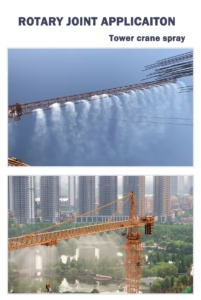

The 360 Degree Tower Crane Spray Universal Rotary Joint is an essential component in modern construction site dust suppression systems. Designed to rotate freely with high-pressure water flow, this multi-directional swivel joint enables consistent and even spraying coverage from the tip of the tower crane jib, ensuring maximum reach and flexibility. It is a precision-engineered rotary union designed specifically for tower crane spraying systems, offering full 360-degree rotation to enable continuous, uninterrupted fluid transfer. Crafted from high-quality materials such as brass or stainless steel, this rotary joint supports high-pressure water, hydraulic oil, air, and other media, ensuring reliable performance in harsh construction environments.

This joint plays a critical role in tower crane spray systems, where dust control, cooling, and environmental compliance are vital. Compatible with various pipe sizes and pressures, it connects the stationary pipework to rotating nozzles and spray heads, allowing full 360-degree rotation without leakage or flow interruption.

Key Features

Key Features

Full-Coverage Spray Radius – Matches Tower Crane Rotation

Our rotary joint enables a 360-degree continuous spray coverage, fully synchronized with the rotational radius of the tower crane.

As the crane rotates during material lifting or movement, the water spray or mist follows the same arc, ensuring no blind spots.

This wide-area atomization capability makes it ideal for large-scale construction zones, high-rise projects, and foundation works.

Effective Dust Suppression & Pollution Control

Equipped with high-pressure nozzles and a leak-free swivel design, this joint forms a fine mist that effectively traps airborne dust particles.

It helps reduce dust concentration, construction haze, and airborne pollutants, significantly improving onsite air quality and visibility.

By keeping suspended particles down, it also minimizes respiratory hazards, controls PM2.5/PM10, and contributes to environmental regulation compliance.

Ground Cooling & Concrete Moisture Retention

In hot summer or dry climates, the rotary joint’s mist spray assists in cooling the work area and lowering surface temperatures.

It prevents overheating of materials and machinery and provides evaporative cooling to improve worker comfort and operational safety.

Additionally, it helps keep poured concrete moist, preventing premature surface cracking, improving curing quality, and extending the structure’s lifespan.

Constitute

Constitute

1. System Composition

The high-altitude spray dust removal system consists of:

🔄 Special rotary universal joint (for tower cranes)

🔩 Support brackets

🚿 Water pipes & adjustable nozzles

🧵 Loose joints & tees

🧹 Water filters

This combination ensures precise spray direction, efficient dust suppression, and easy maintenance.

💧 2. Water Supply Options

Two flexible intake methods are available:

🌐 Municipal pipeline connection

Connect directly to the city water supply

♻️ Recycling system integration

Use recovered water with a pressurized pump to deliver to the tower crane’s spray system.

Piping setup

1. Sprinkler Layout Planning

Sprinkler heads are installed every 2–3 meters along the rotating arm.

Water pump, piping, and universal joint types are selected based on:

💧 Required water flow

⚙️ Pressure per sprinkler head

The layout must adapt to on-site conditions and application needs.

2. System Integration & Support Structure

The pipeline and spray universal joint are installed in line with the tower crane’s rotating wheel core.

Ensures the entire system is coaxial and concentric for reliable operation.

Welding is prohibited on standard tower crane parts.

3. Fixed Support Design

A special rotary universal joint uses two fixed supports.

Supports are secured via screw buckles, ensuring modularity and maintenance access.

The pipe support is also screw-connected directly to the crane for seamless integration.

Tower Crane Spray System – Important Precautions

🔍 1. Routine Inspection

Regularly check if the pipe support and universal joint bracket are:

🧰 Shifted or misaligned

🔩 Loose or unfastened

Ensure structural safety and system stability.

🚰 2. Long-Distance Pipe Layout

When the main spray pipe exceeds 200 meters,

It is recommended to:

🔄 Install booster pumps at regular intervals

✅ Maintain consistent water pressure and spray efficiency

❄️ 3. Winter Protection (Northern Regions)

To prevent pipe freezing:

🌡️ Bury main pipelines ≥ 1 meter deep

🧣 Apply thermal insulation or heating measures

📌 Best Practices

Perform seasonal maintenance checks.

Follow regional climate guidelines

Use quality fasteners and insulation materials

Why Choose Our Tower Crane Spray Rotary Joint?

Superior Durability

Made from corrosion-resistant brass or stainless steel, our rotary joints withstand harsh weather, saltwater exposure, and abrasive environments common in construction.

Leak-Free Operation

Balanced seals and precision machining ensure minimal leakage, maintaining system efficiency and reducing fluid loss.

Easy Installation and Maintenance

Threaded and flange connections simplify integration; replacement seal and bearing kits are available for on-site maintenance.

Customizable Solutions

We offer OEM/ODM customization to meet unique project specifications, including size, pressure rating, and seal materials.

Cost-Effective

Competitive pricing combined with long service life reduces the total cost of ownership.

Conclusion

For reliable, continuous 360-degree fluid transfer in tower crane spray systems, our 360 Degree Tower Crane Spray Universal Rotary Joint offers unmatched performance, durability, and value. Engineered for high pressure and harsh environments, it ensures leak-free operation and easy maintenance, making it the ideal choice for construction, dust control, and hydraulic applications.

Order now to enhance your tower crane’s spraying efficiency and reduce maintenance costs with our premium rotary joint solutions.