Hydraulic High Pressure Right Angle 90 Degree Rotary Union

Original price was: $30.00.$26.00Current price is: $26.00.

- Material: Stainless steel

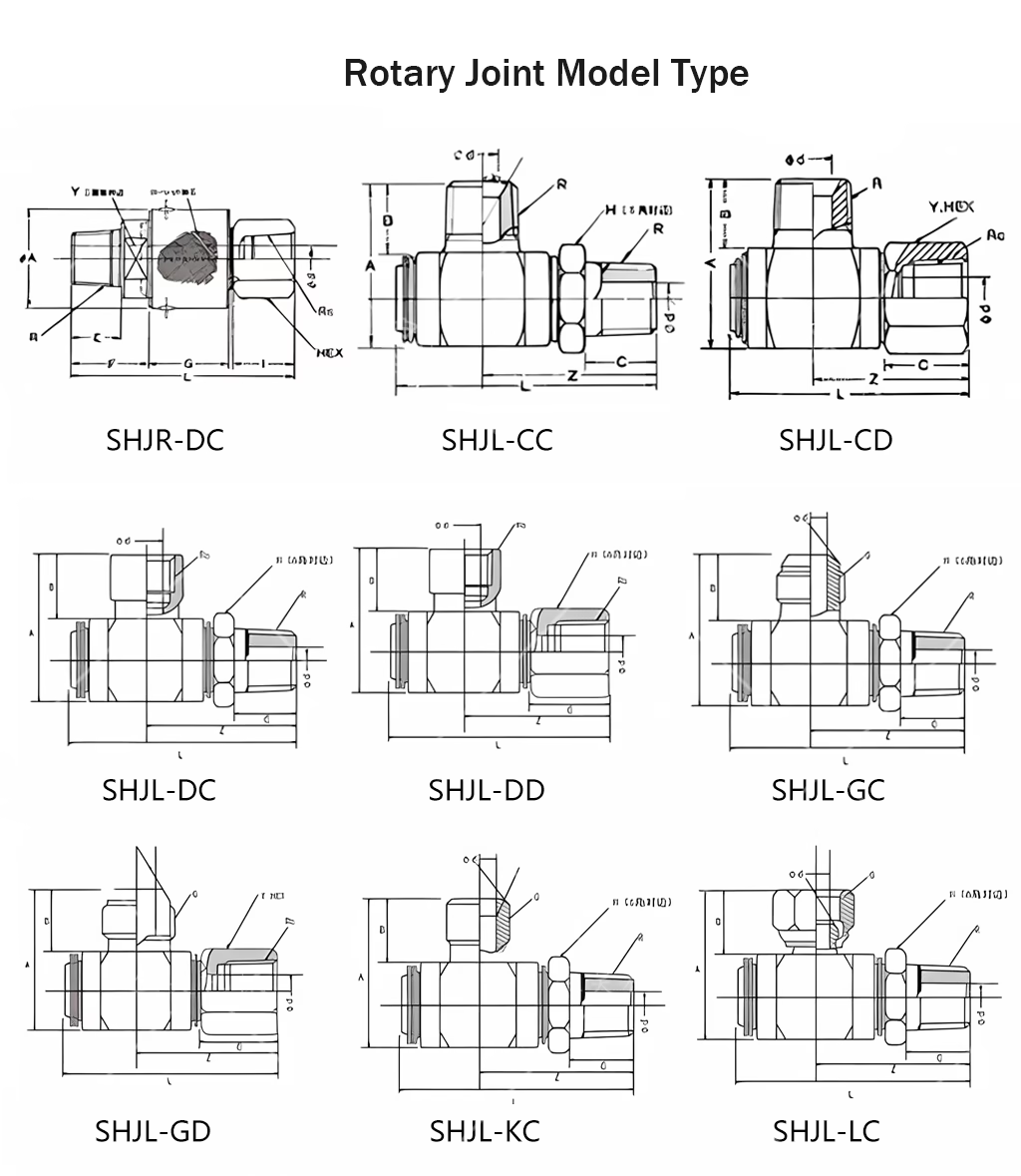

- Size: All kinds of models and sizes can be customized.

- Max.Speed: ≤200RPM;

- Max. Pressure: ≤35Mpa;

- Max. Temperature: ≤121℃;

- Applicable medium: Hydraulic oil, water, gas, organic solvent.

Description

Product Overview: 90 Degree Rotary Union

The 90 Degree Rotary Union, also known as a Right Angle Hydraulic Rotary Union, is an industrial-grade rotating connector designed to transfer fluid—such as hydraulic oil, water, steam, or compressed air—between stationary and rotating equipment components at a 90-degree interface. This right-angle configuration makes it ideal for use in compact or limited-space environments where conventional straight-through rotary unions may not fit.

Engineered for durability, high pressure, and smooth rotation, our 90° rotary joint ensures efficient fluid delivery with minimal leakage and maintenance, making it a critical component in today’s high-performance hydraulic and pneumatic systems.

Key Features of 90 Degree Rotary Union

🔄 90-Degree Swivel Design

Optimized for tight space applications where axial installation is not possible; Reduces system footprint and simplifies hose routing.

💪 High Pressure & High-Speed Performance

Handles pressures up to 4000 PSI (275 bar) and speeds up to 3000 RPM; Ensures stable fluid transfer under dynamic rotation.

🔒 Advanced Sealing Technology

Incorporates high-performance seals to ensure leak-free operation; Suitable for steam, heat transfer oil, hydraulic oil, and other demanding media.

🔧 Robust & Corrosion-Resistant Build

Body materials include hardened stainless steel, carbon steel, or anodized aluminum; Corrosion protection suitable for harsh environments (marine, industrial, etc.).

⚙️ Pre-Lubricated Bearing System

Integrated precision bearings ensure low-friction, smooth rotation, and extended service life; Factory-filled grease makes it maintenance-free during typical operation cycles.

🔄 Flexible Connection Options

Available with NPT, BSP, SAE threads, or flange interfaces; Supports single-channel and multi-channel (multi-passage) models.

| Specification | Value |

|---|---|

| Product Name | 90 Degree Rotary Union / Right Angle Rotary Union |

| Number of Passages | 1 to 4 channels |

| Max Pressure | Up to 4000 PSI (customizable) |

| Max Rotational Speed | Up to 3000 RPM |

| Operating Temperature | -30°C to +220°C (varies by seal material) |

| Media Supported | Hydraulic oil, air, water, steam, coolant |

| Body Material | Stainless Steel / Carbon Steel / Aluminum |

| Seal Type | Mechanical seal / Elastomer seal |

| Thread Type | BSP, NPT, SAE, Flanged |

Applications of 90 Degree Rotary Union

Applications of 90 Degree Rotary Union

Hydraulic Systems

They are commonly used in hydraulic machinery, such as excavators and hydraulic presses, to facilitate the transfer of hydraulic fluids. Their compact design allows for efficient fluid flow while accommodating the space constraints often found in hydraulic applications.

Automotive Manufacturing

In automotive assembly lines, these rotary unions are essential for delivering lubricants and hydraulic fluids to rotating components. They support robotic arms and other machinery that require fluid transfer during assembly processes, ensuring smooth operation and efficiency.

Car Wash Systems

These unions are utilized in car wash equipment to enable high-pressure water delivery. This application is critical for effective vehicle cleaning, allowing for continuous fluid flow while the washing apparatus rotates.

Industrial Cleaning Equipment

These rotary unions are integral to pressure washers and other industrial cleaning machines, where they provide a reliable connection for transferring cleaning solutions under high pressure. Their design ensures that fluid flow remains uninterrupted during operation.

Food Processing

In the food processing industry, these unions are used to transfer steam or hot water to various equipment, such as mixers and cookers. Their ability to withstand high temperatures and pressures makes them suitable for sanitary food applications.

Textile Manufacturing

In textile production, these rotary unions facilitate the transfer of steam or hot water to dyeing machines and rollers. This ensures uniform heating and treatment of fabrics during production processes.

📦 Packaging & Delivery

📦 Packaging & Delivery

Packaging: Protective foam box or custom wooden case for export.

Lead Time: 3-5 working days, depending on order quantity.

Shipping Options: DHL, FedEx, TNT, UPS, air freight, sea freight.

FAQ of 90 Degree Rotary Union

What is a 90 90-degree rotary Union used for?

The 90 Degree Rotary Union, also called a Right Angle Hydraulic Rotary Union, is used to transfer fluid (hydraulic oil, air, water, or steam) between stationary and rotating parts at a 90° angle. It is ideal for space-constrained applications like robotic arms, injection molding machines, and construction equipment.

What media can this rotary union handle?

Our rotary unions support a wide range of media, including: Hydraulic oil, Pneumatic air, Water and coolant, and Steam and heat transfer oil. If you’re using corrosive or high-temperature media, please contact us to select the right seal and material combination.

Is this union suitable for high-temperature applications?

Yes. When used with the appropriate high-temperature seals and thermal-resistant materials, it can handle temperatures up to 220°C. For steam or heat transfer oil, we recommend applying high-temperature sealant during installation.

Can I use this rotary union in multi-passage systems?

Yes. We offer single-passage and multi-passage rotary unions (2–4 channels) for simultaneous transmission of multiple fluids or a mix of fluid and electrical signals (when combined with slip rings).

Can you provide CAD drawings or 3D models?

Yes. We offer 2D CAD drawings and STEP/IGES 3D files to support your design and integration process. Just send us your model requirements or operating parameters.

Do you support OEM or customized solutions?

Absolutely. We specialize in OEM rotary union solutions, including: Custom sizes and port configurations, Specific sealing materials, and Custom branding or laser marking.

📞 Get a Quote or Free Consultation

📞 Get a Quote or Free Consultation

Ready to improve your system’s fluid transfer efficiency with a 90 90-degree rotary Union? Contact our sales team for personalized solutions, free CAD drawings, or bulk pricing.

📧 Email: sales@dannhydraulic.com

📞 Phone: +86-15122592153

🌐 Website: www.dannhydraulic.com