Deublin 902-141-192

- Part Number:902-141-192

- Max Coolant Pressure: 10 bar (145 psi)

- Max Speed:20,000 RPM

- Max Flow Rate:15 l/min (3.96 GPM)

- Max Temperature:70 °C (158 °F)

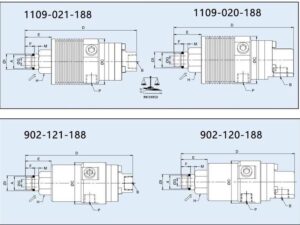

- Rotor Connection Type:Axial and Radial

Description

Key Features

Key Features

Monoflow Design: This rotary union features a single passage design that enables effective coolant or Minimum Quantity Lubrication (MQL) delivery, optimizing fluid flow for various applications.

Self-Supported Construction: The self-supported design minimizes the need for additional support structures, simplifying installation and reducing overall system complexity.

High-Wear Resistant Seals: Equipped with balanced mechanical seals made from silicon carbide, the Deublin 902-141-192 ensures durability and longevity even under demanding conditions.

Pop-Off™ Technology: This innovative technology allows for unlimited dry running without media pressure, making it perfect for applications where fluid presence may not always be guaranteed.

Robust Bearings: The rotary union utilizes high-precision angular contact ball bearings arranged in an X-pattern, providing smooth operation and stability at high speeds.

Corrosion-Resistant Housing: Constructed from anodized aluminum, the housing protects against corrosion and wear, extending the service life of the unit.

Deublin 902-141-192 Rotary Union: Product Overview

The Deublin 902-141-192 Rotary Union is a state-of-the-art solution designed for efficient fluid transfer in rotating applications. With its advanced engineering and robust construction, this rotary union is ideal for a wide range of industrial applications, ensuring reliable performance and enhanced productivity.

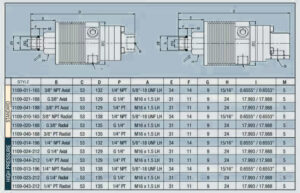

Technical Specifications of Deublin 902-141-192 Rotary Union

Technical Specifications of Deublin 902-141-192 Rotary Union

Part Number:902-141-192

Part Number:902-141-192

Max Coolant Pressure: 10 bar (145 psi)

Max Speed:20,000 RPM

Max Flow Rate:15 l/min (3.96 GPM)

Max Temperature:70 °C (158 °F)

Rotor Connection Type:Axial and Radial

The Deublin 902-141-192 Rotary Union is a versatile component that provides significant benefits across various industries. Here are the key industries that benefit the most from using this rotary union:

Machine Tool Manufacturing

Applications: CNC machines, machining centers, and transfer lines.

Benefits: The rotary union allows for effective coolant delivery, which helps in cooling cutting tools and removing chips, thereby enhancing machining precision and extending tool life.

Automotive Industry

Applications: Used in assembly lines and machining operations for automotive components.

Benefits: Ensures consistent lubrication and cooling during high-speed operations, improving efficiency and reducing wear on machinery.

Aerospace Engineering

Applications: Machining of aircraft components and assembly processes.

Benefits: Provides reliable coolant flow, essential for maintaining dimensional accuracy and preventing overheating during critical machining operations.

Robotics and Automation

Applications: Integrated into robotic arms and automated systems where fluid transfer is necessary.

Benefits: Supports continuous operation without interruptions, essential for maintaining productivity in automated environments.

Food and Beverage Processing

Applications: Used in equipment that requires sanitary fluid transfer, such as cooling systems in food processing machinery.

Benefits: The corrosion-resistant housing ensures compliance with hygiene standards while providing reliable operation under pressure.

Textile Machinery

Applications: Employed in machines that require lubrication or cooling during fabric processing.

Benefits: The rotary union ensures continuous operation without interruptions, which is critical for maintaining production efficiency in textile manufacturing.

Plastics and Injection Molding

Applications: Utilized in injection molding machines to provide cooling during the molding process.

Benefits: Helps maintain optimal temperatures to prevent defects in molded products, enhancing quality control.

Metalworking

Applications: Used in various metalworking processes, including grinding and milling.

Benefits: Facilitates efficient coolant delivery to reduce heat generation and improve surface finish on machined parts.

Construction Equipment

Applications: Integrated into hydraulic systems of construction machinery.

Benefits: Provides reliable fluid transfer for hydraulic operations, enhancing the performance of equipment like excavators and cranes.

Marine Applications

Applications: Used in shipbuilding and maintenance for cooling systems.

Benefits: Ensures efficient fluid transfer under challenging conditions, contributing to the reliability of marine machinery. FAQ of deublin 902-141-192

FAQ of deublin 902-141-192

What is the Deublin 902-141-192 Rotary Union?

The Deublin 902-141-192 is a rotary union designed for the efficient transfer of coolant and Minimum Quantity Lubrication (MQL). It features a single passage design and is equipped with Pop-Off™ technology, allowing for unlimited dry running without media pressure, making it ideal for various industrial applications.

What materials are used in the construction of the Deublin 902-141-192?

The rotary union features an anodized aluminum housing that resists corrosion, along with balanced mechanical seals made from silicon carbide, which provide longevity and reliability even under challenging operating conditions.

What industries commonly use the Deublin 902-141-192?

Industries that benefit from this rotary union include:Machine Tool Manufacturing,Automotive Production,Aerospace Engineering, Robotics and Automation,Food and Beverage Processing.

What are the installation requirements for the Deublin 902-141-192?

The rotary union has a threaded rotor connection (M16x1.5 LH) and a housing connection of 3/8″-19 PT, making installation straightforward. Proper alignment with the spindle is crucial to avoid vibration during operation.

How does the design prevent contamination?

The full-flow design of 902-141-192 minimizes obstructions that could trap debris or swarf, ensuring a clean fluid path and prevent contamination in sensitive applications like machining.

What maintenance is required for the Deublin rotary union?

Regular maintenance includes checking seals and bearings for wear, ensuring cleanliness during installation, and adhering to specified tolerances for spindle connections to maintain optimal performance and extend service life.

Is the Deublin 902-141-192 Rotary Union suitable for high-speed applications?

Yes, it is designed to operate at high speeds (up to 20,000 RPM), making it suitable for demanding environments such as CNC machining where precision cooling is critical.