High Speed Brass Rotary Union Water Rotary Union Manufacturers

Original price was: $20.00.$15.00Current price is: $15.00.

- Material: Brass

- Max Pressur: Up to 10 MPa

- Max Speed: Up to 1000 RPM

- Port Size: 1/8″ to 6″

- Seal Type: Nitrile / Fluoropolymer

- Operating Temperature: -20°C to 120°C

Description

Brass Rotary Union Water Rotary Union: Product Details

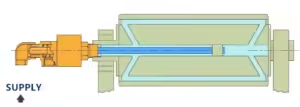

The Brass Rotary Union is a precision-engineered component designed to facilitate seamless fluid transfer between stationary and rotating systems in industrial environments. Crafted from high-grade brass alloys, this rotary union combines corrosion resistance, thermal conductivity, and mechanical durability to excel in diverse applications—from plumbing and HVAC systems to manufacturing machinery. Engineered with advanced sealing technologies and versatile connection designs, brass rotary unions ensure leak-free operation, minimal maintenance, and long-term reliability across high-temperature, high-pressure, and corrosive media conditions.

We specially designed this series of rotary joints for cooling. It has the characteristics of small size, light weight, small friction torque, etc. It adopts flat sealing technology. The friction pair materials are selected according to the medium environment. Various impregnated graphite, bronze, tungsten carbide, and silicon nitride pairs are selected, which are enough to resist the influence of rust, scaling, debris, and other impurities on the sealing surface. Our seals are made on CNC machine tools and special grinders. The surface is like a mirror, which makes the seal more reliable. At the same time, we use high-precision rolling bearings to make it rotate smoothly. We install graphite rings, silicon carbide, and tungsten carbide seals inside to ensure a simple structure, easy maintenance, and reliable sealing. We recommend connecting the rotary joint and the pipeline with metal hoses.

Use graphite rings, silicon carbide, and tungsten carbide seals internally for their simple structure, easy maintenance, and reliable sealing. We recommend connecting the rotary joint and the pipeline with metal hoses.

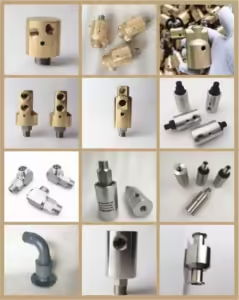

Silicon carbide ring

The crystal structure of silicon carbide is similar to the regular tetrahedral structure of diamond. The combined compound has high hardness (Mohs 9.3) and stable performance, and its physical properties are more similar to diamond. It has excellent properties such as high hardness, good wear resistance, strong thermal stability, good shock resistance, large thermal conductivity, and resistance to thermal chemical corrosion, especially the characteristic of being insensitive to the attack angle of abrasives.

Fluororubber O-ring

It is made of fluororubber (FKM or VITON) and is also one of the most widely used sealing products. Fluororubber has high temperature resistance and can be used in an environment of -40°~240°. It is resistant to strong oxidants, oil, acid, and alkali, and can be used in high vacuum and high altitude environments. It is also suitable for oil environments.

Genuine bearings

The most representative rolling bearings, with a wide range of uses, can withstand radial loads and bidirectional axial loads. Suitable for high-speed rotation and low-noise, low-vibration occasions. Manufacturers pre-fill sealed bearings with steel dust covers or rubber sealing rings with an appropriate amount of grease. Bearings with retaining rings or flanges on the outer rings are easy to locate in the axial direction and convenient to install in the housing.

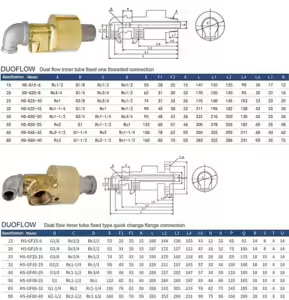

| Model | HD one-way flow type, HS-G two-way flow type |

|---|---|

| Pressure | 1.0MPa high pressure can be customized |

| Temperature | 100℃ high temperature can be customized |

| Speed | 0-1000r/min high speed can be customized |

| Medium | water, air, salt water, hydraulic oil, steam, etc. |

| Size | DN8~DN100 1/4 inch-4 inch |

| Connection method | threaded connection |

| Standard | BSP NPT metric |

| Material | stainless steel 304/copper |

| Seal | carbide/ordinary graphite |

| Bearing | MSK/SKF/HRB |

Product Features of Brass Rotary Union

- The joint itself can rotate 360 degrees, regardless of left or right; the so-called left and right rotation refers to the direction of the thread, that is, whether the teeth of the connecting device are right or left.

- Our team exquisitely processes the details of this product, guarantees its quality, and ensures it is smooth and burr-free. The product layout is reasonable, and the structure is simple. Our R&D personnel continuously improve and innovate the product structure, resulting in better quality and longer service life.

- This series of rotary joints uses high-quality silicon carbide + graphite seal + pressure-resistant high-speed accessories for rotational lubrication and flexible steering.

- It adopts lean technology to make every product well. Each product undergoes strict quality inspection before leaving the factory and meets industrial standards.

Application of Brass Rotary Union

It is widely used in plastic calendering, internal mixer, hydraulic equipment, coating machinery, and other equipment using high temperature oil or steam, and is mainly used in cooling systems in leather, papermaking, textile, metallurgy, and other industries.

🚰 1. Plumbing & Water Management

- Hot Water Systems: Transfers heated water in rotating boilers and solar thermal collectors.

- Irrigation Equipment: Enables 360° rotation in sprinklers and agricultural sprayers.

- Marine Plumbing: Corrosion-resistant brass withstands saltwater in shipboard systems.

🏭 2. Industrial Manufacturing

- Plastic Extrusion: Maintains coolant flow in rotating dies for product consistency.

- Food Processing: Uses FDA-compliant hygienic brass in conveyors and mixing tanks.

- Printing Presses: Transfers ink and lubricants in high-speed rotary equipment.

❄️ 3. HVAC & Refrigeration

- Chiller Systems: Connects rotating compressors to stationary refrigerant lines.

- Air Handling Units: Facilitate coolant flow in rotating heat exchangers.

- Steam Applications: Transfers low-pressure steam (up to 100 PSI) in heating coils.

🚗 4. Automotive & Aerospace

- Engine Testing: Routes coolant and oil in rotating engine dynamometers.

- Aero Components: Lightweight brass unions for fuel transfer in aircraft ground support.

- Hydraulic Systems: Support fluid power in rotating actuators for robots.

Why Choose Our Brass Rotary Union?

🥇 Material Advantages

- Corrosion Resistance: Brass outperforms steel in water and mildly acidic environments, reducing maintenance costs.

- Electrical Conductivity: Suitable for grounding in explosive environments (ATEX-compliant available).

Cost-Effectiveness: Brass provides durability at a lower cost than stainless steel or bronze.

🛠️ Design Innovations

- Modular Construction: Replaceable seal cartridges for fast, easy maintenance.

- Balanced Seal Technology: Reduces face loading, extends seal life by 50% vs. unbalanced seals.

- Pressure-Compensated Design: Automatically adjusts seal force for stable, leak-free performance.

✅ Industry Compliance

- Standards:

✔️ ASME B1.20.1 (Threading)

✔️ ISO 681 (Hydraulic Connections)

✔️ NSF 61 (Potable Water) - Certifications:

✔️ CE Marked (EU Compliance)

✔️ USDA-Approved Alloys (Food Processing)

FAQ

Q1: Can brass rotary unions handle abrasive fluids?

A: While brass is durable, abrasive media (e.g., slurries) may require stainless steel or ceramic-coated components. Consult our engineering team for custom solutions.

Q2: How does brass compare to stainless steel in high-temperature applications?

A: Brass performs well up to 150°C, but stainless steel is preferred above 200°C. For extreme heat, consider our brass unions with heat-resistant seals.

Q3: Are brass unions suitable for gas applications?

A: Yes, People commonly use brass for compressed air and natural gas systems. Ensure proper pressure rating and use gas-specific seals (e.g., Viton).

Q4: What is the expected service life of a brass rotary union?

A: With proper maintenance, most unions last 5-7 years in typical industrial use. Harsh environments may reduce this to 3-4 years.

Q5: Can I use a brass union in a vacuum system?

A: Brass unions can handle vacuum conditions down to 29″ Hg, but consult our specs for models optimized for vacuum service.

Conclusion

The Brass Rotary Union is a versatile, reliable solution for fluid transfer in rotating systems. Its combination of corrosion-resistant brass construction, advanced sealing technologies, and adaptable designs makes it an ideal choice for plumbing, industrial manufacturing, HVAC, and more. Whether you need to transfer water, oil, gas, or other media, brass rotary unions deliver consistent performance, minimal downtime, and long-term value.

Order Today to experience the durability and efficiency of premium brass engineering in your fluid transfer systems.