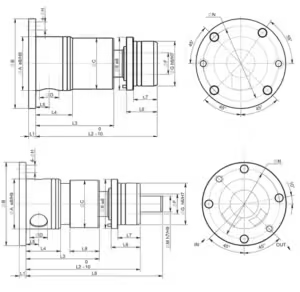

Continuous Casting Machine Embedded Rotary Union

Original price was: $45.00.$42.00Current price is: $42.00.

- Max.Speed:60RPM

- Max. Pressure:1.2mpa

- Max. Temperature:120 degrees

- Applicable medium:Water, coolant

- Model: Embedded rotary joint for continuous casting machine

Description

The Continuous Casting Machine Embedded Rotary Union is a precision-engineered rotary joint designed for demanding steel manufacturing environments. Built to withstand high temperatures, abrasive conditions, and continuous operation, this rotary union ensures uninterrupted fluid transfer of water, steam, oil, or coolant in continuous casting machines (CCM).

Unlike standard rotary joints, the embedded design integrates seamlessly into the casting machine, reducing installation space and increasing system stability. Whether you are operating in large-scale steel plants or specialized casting workshops, this rotary union delivers maximum reliability, longer service life, and reduced downtime.

In the relentless, high-temperature environment of continuous steel casting, every component’s reliability is paramount. Unscheduled downtime is not just an inconvenience; it’s a significant loss of production and profitability. The Continuous Casting Machine Embedded Rotary Union is the core component that ensures the consistent and efficient cooling of your caster rolls, a critical factor in producing high-quality steel. Our expertly engineered rotary union (also known as a rotary joint or fluid swivel) is designed to withstand the harshest conditions of a steel mill, providing a steadfast and leak-proof conduit for cooling water, hydraulic oil, and other essential fluids to the heart of your rotating machinery.

This is not merely a replacement part; it is a strategic upgrade for your continuous casting machine (CCM). By integrating our heavy-duty rotary union, you are investing in operational stability, reduced maintenance, and the long-term integrity of your steel production line.

Key Features & Benefits

Heavy-Duty Construction

Manufactured with hardened alloy steel and anti-corrosion coatings for extreme durability.

Resistant to thermal expansion, scale buildup, and abrasion caused by molten steel environments.

High-Temperature & High-Pressure Resistance

Operates reliably under cooling water pressures up to 25 bar.

Designed for continuous thermal cycling in casting operations.

Precision Sealing Technology

Equipped with balanced mechanical seals to prevent leakage.

Seal options include carbon-graphite, silicon carbide, and tungsten carbide for different media.

Embedded, Space-Saving Design

Fits directly into the continuous casting machine rollers.

Reduces external piping and minimizes leakage risk.

Low Maintenance & Long Service Life

Integrated self-lubricating components reduce wear.

Easy seal replacement design lowers downtime.

Cost-Effective Alternative to Deublin & Kadant

Delivers comparable performance at a more competitive price.

Ideal for steel manufacturers seeking affordable, reliable rotary unions.

Applications in Continuous Casting Machines

The embedded rotary union is a mission-critical component in continuous casting machines (CCM) used in steel plants. Its primary role is to transfer cooling water into rotating rollers during the casting process.

Key Applications:

-

Cooling Rollers – Ensures efficient cooling of billets, blooms, and slabs.

-

Secondary Cooling Zone – Maintains uniform solidification of molten steel.

-

Hydraulic Media Transfer – Supplies lubrication and pressure control fluids.

-

Automation Systems – Integrated into automated steel casting equipment for uninterrupted performance.

By guaranteeing leak-free cooling water delivery, this rotary union helps prevent roller damage, improve casting surface quality, and extend equipment life.

The Strategic Advantage for Your Steel Mill: A Deeper Dive into the Benefits

Investing in a high-performance rotary union is a decision that pays dividends in multiple areas of your operation. Here’s how our Continuous Casting Machine Embedded Rotary Union can enhance your manufacturing process:

For the Plant Manager and Production Supervisor:

- Increased Uptime and Production Output: The exceptional reliability and long service life of our rotary union translate directly to reduced unscheduled downtime. By minimizing interruptions for repairs and replacements, you can maximize your production output and meet your targets more consistently.

- Improved Product Quality and Consistency: The consistent and efficient cooling provided by our rotary union ensures a more uniform solidification process. This leads to a higher quality final product with fewer surface defects and a more consistent metallurgical structure. This can result in a premium price for your steel and enhanced customer satisfaction.

- Enhanced Operational Safety: Leaking hydraulic fluid or cooling water in a steel mill is a significant safety hazard. Our leak-proof design minimizes the risk of slips, falls, and equipment damage, contributing to a safer working environment for your team.

For the Maintenance Supervisor and Engineering Team:

- Reduced Maintenance Costs: The durable construction and advanced sealing technology of our rotary union significantly extend its service life, reducing the frequency of replacements and the associated labor costs. The low-maintenance design also frees up your maintenance team to focus on other critical tasks.

- Simplified Maintenance Procedures: When maintenance is required, the simple and robust design of our rotary union allows for quick and easy servicing. This minimizes the time your continuous casting machine is out of operation, a critical factor in a high-volume production environment.

- Proactive Maintenance and Troubleshooting: The design of our rotary union allows for easy visual inspection for any potential issues, enabling a proactive approach to maintenance. We also provide comprehensive installation and maintenance guides to ensure your team has the information they need to keep your equipment running smoothly.

The Procurement Manager and Purchasing Department:

- Lower Total Cost of Ownership: While the initial investment in a premium rotary union may be higher than for a standard component, the extended service life, reduced maintenance requirements, and prevention of costly downtime result in a significantly lower total cost of ownership over the long term. This is a smart investment that delivers a clear return.

- Reliable Supply Chain and Expert Support: We are committed to being a reliable partner for your operation. We maintain a robust inventory to ensure prompt delivery and are backed by a team of technical experts who can provide support and guidance to ensure you select the right rotary union for your specific application.

- Long-Term Value and Peace of Mind: By choosing our high-performance rotary union, you are investing in the long-term reliability and efficiency of your continuous casting operation. This provides peace of mind and allows you to focus on your core business of producing high-quality steel.

FAQ

Q1: What makes the embedded design better than external rotary unions?

A1: The embedded design reduces installation space, minimizes leakage, and provides better alignment with casting rollers.

Q2: Can this rotary union handle both water and hydraulic oil?

A2: Yes, it is compatible with multiple media types, including cooling water, hydraulic oil, and steam.

Q3: How does this compare to Deublin rotary unions?

A3: Our product matches Deublin in performance and reliability but comes at a more cost-effective price point.

Q4: Is customization available?

A4: Yes, we provide customized seal materials, pressure ratings, and mounting sizes to fit different casting machine models.

Q5: What is the expected service life?

A5: With proper maintenance, service life exceeds 5 years in continuous operation.

Conclusion & Call to Action

The Continuous Casting Machine Embedded Rotary Union is a high-performance, durable, and cost-effective solution for steel manufacturing plants seeking reliable cooling and media transfer in casting rollers.

With advanced sealing technology, high-pressure tolerance, and long service life, this rotary union ensures smooth casting operations, reduced downtime, and lower costs.

👉 Upgrade your steel production efficiency today with our Continuous Casting Machine Embedded Rotary Union – the trusted choice for modern steel plants worldwide.