Coolant Rotary Union

Original price was: $130.00.$128.00Current price is: $128.00.

- Speed: 4000-15000rpm

- Temperature Range: -30~+95°c

- Pressure: 70-100bar

- Working Medium: Hydraulic oil, water, coolant

Description

Coolant Rotary Union: Enhance Your Machinery’s Efficiency

Introducing our Coolant Rotary Union, a cutting-edge solution designed for the efficient transfer of coolant fluids in high-speed machining applications. Engineered for performance and reliability, this rotary union is essential for industries that demand precision and durability.

Material Options

Material Options

Our Coolant Rotary Union can be customized with various materials to meet specific application needs:

Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC)

Elastomers: Viton, Neoprene, EPDM, NBR

Construction Materials: Stainless Steel 316, Brass, Carbon Steel, Aluminum Key Features

Key Features

High-Speed Performance: Capable of operating at speeds up to 15,000 RPM, our Coolant Rotary Union ensures optimal coolant flow, reducing tool wear and enhancing machining efficiency.

Robust Construction: Made with an aluminum housing and stainless steel internal components, this union is built to withstand harsh conditions while maintaining a lightweight profile.

Advanced Sealing Technology: Equipped with balanced Silicon Carbide mechanical seals, our rotary union minimizes friction and wear, ensuring a long service life even under demanding operational conditions.

Versatile Connections: The design includes both axial and radial inlet connections, making installation straightforward and adaptable to various machinery setups.

Easy Maintenance: Featuring a design that allows for the quick replacement of seals, maintenance is hassle-free, ensuring minimal downtime.

The Coolant Rotary Union is ideal for:

Machine Tools: Essential for CNC machines and milling applications where coolant flow is critical.

Hydraulic Systems: Efficiently transfers hydraulic fluids in various industrial settings.

MQL (Minimum Quantity Lubrication): Supports advanced lubrication techniques that enhance tool life while reducing coolant usage.

Why Choose Our Coolant Rotary Union?

Enhanced Productivity: By maintaining optimal temperatures and reducing friction during machining processes, our rotary union helps increase productivity.

Cost-Effective Solution: The durable design reduces the frequency of replacements and maintenance costs, providing long-term savings.

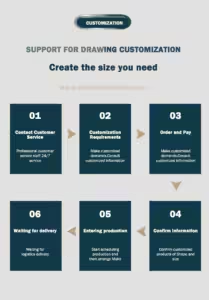

Tailored Solutions: We offer customization options to ensure that our rotary unions meet the specific needs of your machinery and operational requirements.

Reliable Performance: With a proven track record in high-pressure and high-speed applications, our Coolant Rotary Union stands out as a leader in the industry.

What is a Coolant Rotary Union?

What is a Coolant Rotary Union?

A Coolant Rotary Union is a specialized device that facilitates the transfer of coolant from a stationary source to a rotating component in machinery. It is crucial for cooling high-speed or high-pressure equipment, preventing overheating and maintaining optimal performance levels in various industrial applications.

How does a Coolant Rotary Union work?

The union operates by allowing coolant to enter through an inlet port, which then travels through internal channels to reach the rotating component. After cooling the part, the coolant returns through an outlet port, creating a continuous circulation loop that helps manage heat effectively.

What are the main applications of Coolant Rotary Unions?

These unions are widely used in industries such as manufacturing (CNC machines, lathes), automotive (engine testing), wind energy (turbine cooling), oil and gas (drilling operations), and plastics (molding processes). They play a vital role in enhancing operational efficiency and prolonging machinery life across these sectors.

What types of Coolant Rotary Unions are available?

Single-Passage Unions: For applications requiring a single coolant channel.

Multiple-Passage Unions: For simultaneous cooling operations with multiple channels.

Coaxial Unions: Combining different fluid and air channels in one compact design for versatile applications.

What materials are used in Coolant Rotary Unions?

These unions are typically constructed from materials like stainless steel, aluminum, and brass for the housing, while seal faces can be made from carbon, silicon carbide, or tungsten carbide to ensure durability and resistance to wear.

How do Coolant Rotary Unions enhance tool life?

By providing efficient heat dissipation and maintaining optimal temperatures during machining processes, these unions help reduce tool wear and extend the lifespan of cutting tools, leading to cost savings and improved productivity.

What maintenance is required for Coolant Rotary Unions?

Regular inspection of seals for wear and leakage is essential. Many designs allow for easy replacement of seals without needing to disassemble the entire unit, facilitating quick maintenance and minimizing downtime.

What are the benefits of using multi-passage Coolant Rotary Unions?

Multi-passage unions offer versatility by allowing multiple cooling channels for different fluids or simultaneous operations. This adaptability makes them suitable for complex industrial applications where efficiency is critical.

What challenges do Coolant Rotary Unions address in high-speed applications?

They are designed to handle high speeds (up to 15,000 RPM) and pressures (up to 50 bar), ensuring reliable coolant flow while minimizing friction and preventing leakage, which is crucial for maintaining performance in demanding environments.

How do rotary unions differ from traditional connectors?

Unlike standard connectors that merely join two components, rotary unions are engineered to manage dynamic conditions such as rotation and pressure changes while ensuring a continuous flow of coolant without leaks. Their advanced sealing technologies make them essential for high-performance machinery.