Dual-Channel High-Pressure Deublin 1114-308-188 rotary union Alternative

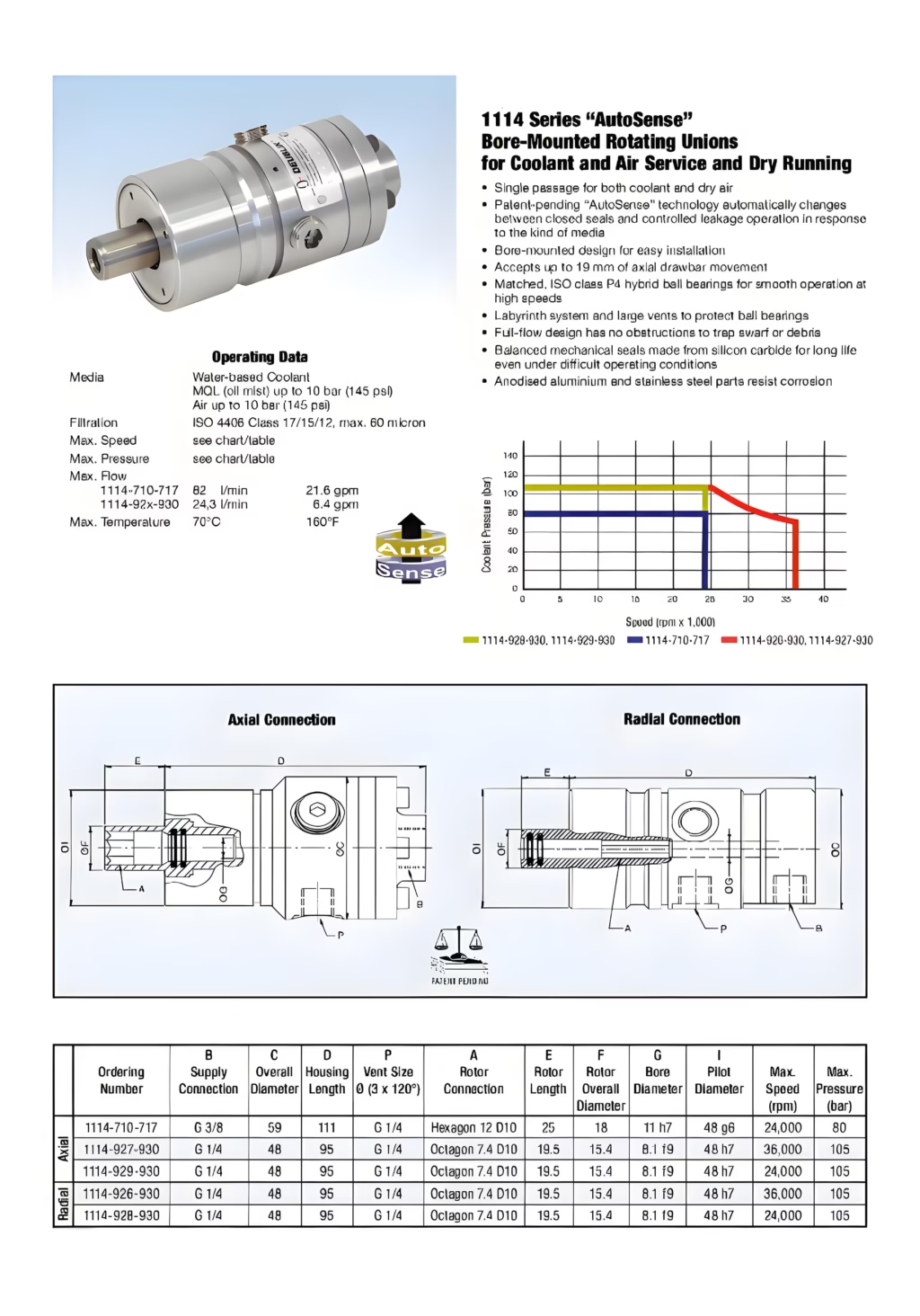

- Medium: Air, coolant, MQL

- Max. Temperature: 71℃

- Max. Pressure: Air: 10 bar; Coolant: 103.4 bar; MQL: 10 bar

- Max. Speed: 20000RPM

- Housing Material: Stainless steel

- Application: General Industry

Description

The Deublin 1114-308-188 Rotary Union Alternative is a precision-engineered dual-channel rotary union designed for high-pressure coolant and air service in CNC machining and metalworking applications. Featuring advanced sealing technology, a bore-mounted design, and a full-flow structure, this rotary union ensures reliable operation in high-speed spindles while extending the life of cutting tools and reducing downtime.

Whether you are machining complex aerospace components, automotive engine parts, or heavy-duty industrial equipment, this dual-passage rotary union alternative delivers exceptional performance at a cost-effective price point. It is fully compatible with Deublin’s 1114-308-188 model and offers a reliable solution for manufacturers seeking a durable, high-performance rotary union without compromising quality.

Key Features

Dual-Channel Design

Supports simultaneous delivery of coolant and air, enabling greater flexibility in machining operations such as through-spindle coolant, dry air blow-off, and tool cleaning.

High-Pressure & High-Speed Capabilities

Designed to handle coolant pressures up to 105 bar and spindle speeds up to 15,000 rpm, ensuring stable performance under demanding machining conditions.

Full-Flow Internal Structure

Built with an unobstructed flow path to prevent debris accumulation, ensuring continuous coolant delivery and improved chip evacuation.

Bore-Mounted Configuration

Compact bore-mounted design allows for easy installation directly into CNC spindles, reducing setup time and ensuring reliable alignment.

Balanced Mechanical Seals

Equipped with silicon carbide balanced seals that withstand abrasive coolant media and ensure long-lasting, leak-free operation.

Labyrinth Bearing Protection

Protects the bearings from coolant contamination, extending service life and reducing maintenance costs.

Hybrid Precision Bearings

Utilizes ISO Class P4 hybrid ball bearings (steel races with ceramic balls) for smooth rotation at high speeds, reducing heat buildup and wear.

Corrosion-Resistant Construction

Features anodized aluminum housing and stainless-steel components, offering superior resistance to rust and coolant-induced corrosion.

Temperature Resilience

Operates efficiently in environments up to 71°C (160°F), maintaining seal integrity and performance during continuous operation.

Cost-Effective Alternative

Provides equivalent performance to the original Deublin 1114-308-188 rotary union at a more competitive price, making it an ideal choice for cost-conscious manufacturers.

Applications

Automotive Industry – High-speed machining of crankshafts, camshafts, and fuel system components.

Aerospace Industry – Deep hole drilling, precision boring, and high-speed milling of turbine shafts, landing gear, and structural parts.

General Machining – CNC milling, drilling, and turning where dual-channel coolant and air service are required.

Oilfield & Energy Equipment – High-precision boring and machining of hydraulic components and drilling tools.

Advantages of Using a Dual-Channel Rotary Union

Flexibility in Media Transfer

Dual-channel design allows delivery of coolant and compressed air through the same rotary union, reducing the need for separate connections and improving efficiency.

Improved Tool Life

High-pressure coolant ensures better lubrication and cooling at the cutting edge, significantly extending tool life and reducing replacement costs.

Enhanced Surface Finish

Consistent coolant flow prevents tool overheating, leading to smoother bore finishes in deep hole drilling and precision machining.

Reduced Downtime

With robust sealing technology and labyrinth bearing protection, this rotary union requires less frequent maintenance, keeping production running smoothly.

Lower Operating Costs

As a cost-effective alternative to the OEM Deublin 1114-308-188, it provides the same high-performance reliability at a reduced investment.

Customer Testimonials

⭐ “Reliable and efficient.”

We switched to this alternative rotary union for our CNC drilling machines. Performance is identical to the OEM Deublin version, but at a much lower cost. – Automotive Manufacturer

⭐ “Perfect replacement.”

Installed easily into our spindles, and it has been running flawlessly at 12,000 rpm with high-pressure coolant. – Aerospace Supplier

Conclusion

The Deublin 1114-308-188 Rotary Union Alternative is a high-performance, dual-channel solution designed to meet the most demanding requirements in CNC machining, deep hole drilling, and high-speed milling. With robust seals, precision bearings, and a corrosion-resistant design, it delivers reliability and durability equal to the OEM Deublin product—at a significantly reduced cost.

Suppose you are looking for a cost-effective alternative to the Deublin 1114-308-188 rotary union that does not compromise on quality or performance. In that case, this dual-channel high-pressure rotary union is the smart choice.

👉 Upgrade your machining efficiency today with our Deublin 1114-308-188 Rotary Union Alternative.