Reliable Rotary Union Replacement | Deublin 1129-036-301 Model

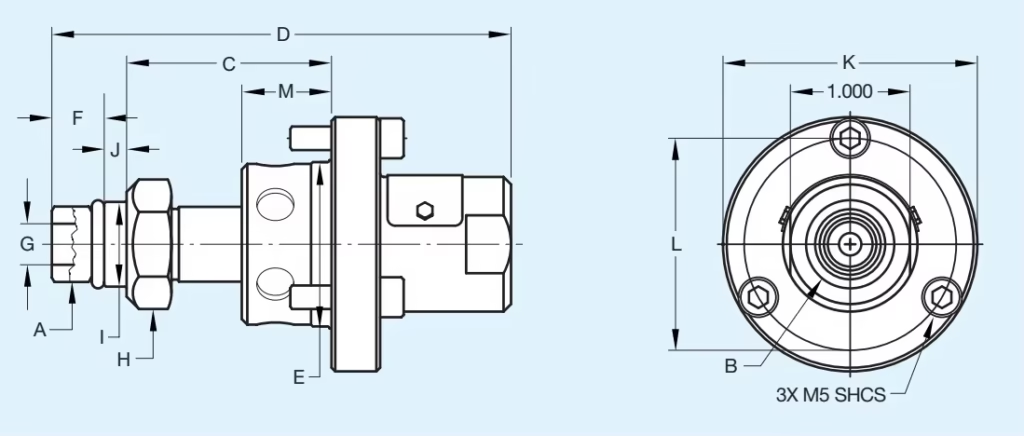

- Medium: coolant

- Max. Temperature: 70℃

- Max. Pressure: 141bar

- Max. Speed: 20000RPM

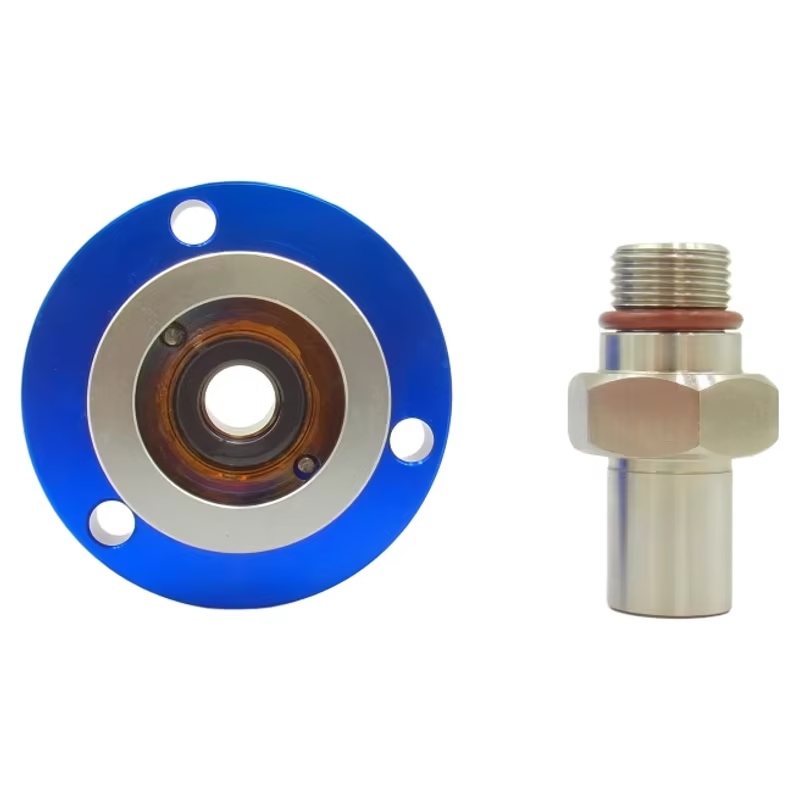

- Housing Material: Aluminum

- Application: General Industry

Description

The Deublin 1129-036-301 Rotary Union is a precision-engineered rotary joint designed to transfer fluids such as coolant, air, water, and hydraulic oil from stationary sources to rotating equipment. Engineered for durability and precision, this rotary union offers a reliable and efficient solution to delivering coolant, air, hydraulic fluid, or other media to rotating equipment components. Built for heavy-duty industrial use, this model ensures stable performance under high pressure, elevated temperatures, and continuous rotational speeds.

As a cost-effective replacement for OEM Deublin rotary unions, the 1129-036-301 offers exceptional durability, leak-free operation, and adaptability across multiple industries. Whether for CNC machining centers, paper manufacturing, printing presses, or automation systems, this rotary union provides engineers, procurement managers, and maintenance teams with a reliable solution that balances high performance with affordability.

Key Features

ELIMINATE DRY RUN FAILURES

The Deublin 1129-036-301 features groundbreaking “Pop-Off” technology. The mechanical seals automatically separate when coolant pressure is absent, allowing for unlimited dry running without wear or damage. This is a crucial advantage for machine tools that run cycles with and without through-spindle coolant (TSC), protecting your investment and preventing catastrophic seal failure.

HIGH-SPEED, HIGH-PRESSURE PERFORMANCE

Engineered for the extreme demands of modern CNC machining, this bearingless rotary union is rated for speeds up to 24,000 RPM and coolant pressures up to 2,000 PSI (140 bar). The advanced Silicon Carbide seal faces ensure minimal friction and superior heat dissipation, making it the perfect choice for high-performance drilling, milling, and tapping operations.

OPTIMIZED FOR COOLANT & MQL

This single-passage monoflow union is designed for both traditional flood coolant and Minimum Quantity Lubrication (MQL) applications. The full-flow design prevents any obstruction, ensuring unrestricted passage of high-pressure coolant or air/oil mist, leading to superior chip evacuation, extended tool life, and improved surface finishes.

SUPERIOR LONGEVITY & RELIABILITY

Featuring balanced mechanical seals made from wear-resistant Silicon Carbide, this rotating joint is built to last in the harshest machining environments. The anodized aluminum housing provides excellent corrosion resistance, while the bearingless design eliminates a common point of failure, resulting in a significantly longer service life compared to conventional coolant unions.

PRECISION ENGINEERING FOR EASY INTEGRATION

Designed for seamless integration into machine tool spindles, the Deublin 1129-036-301 features an M16x1.5 left-hand threaded rotor with a precision 18mm pilot. Its compact, lightweight design minimizes spindle load and simplifies installation, making it an ideal upgrade or replacement for underperforming rotating couplings.

The Heart of High-Efficiency Machining Centers

The Deublin 1129-036-301 rotating union is the trusted choice for a wide range of high-precision machining operations where reliable through-spindle fluid delivery is paramount.

Vertical & Horizontal Machining Centers (VMC / HMC)

Delivers high-pressure coolant directly through the spindle to the cutting edge of drills, end mills, and facemills, enabling higher feed rates, deeper cuts, and superior chip control.

Swiss-Type Lathes & Turning Centers

Provides the critical coolant flow needed for deep-hole drilling and complex turning operations on high-value components.

Gundrilling Machines

Ensures a consistent, high-pressure flow of cutting oil, which is essential for lubricating the tool, flushing chips, and achieving tight tolerances in deep-hole applications.

Transfer Lines & Automated Cells

The extreme reliability of the “Pop-Off” design makes it ideal for high-volume, automated production environments where downtime is unacceptable.

MQL (Minimum Quantity Lubrication) Systems

Perfectly suited for near-dry machining, this union can handle the switch between MQL air/oil mist and dry running seamlessly, making it an essential component for green manufacturing initiatives.

Best Practices for Maximizing Performance and Lifespan

To achieve the maximum service life from your Deublin 1129-036-301 rotating joint, proper handling and installation are key.

Clean Environment: The bearingless design requires a clean spindle bore. Ensure the spindle housing is free from any chips, debris, or rust before installation.

Precision Alignment: The union’s performance relies on the precision of the machine spindle. The spindle pilot bore must be concentric with the spindle centerline to ensure the union runs true.

Use of an Anti-Rotation Pin: The housing of the union must be prevented from rotating with the spindle. Use a properly installed anti-rotation pin or bracket that engages with the housing’s vent holes or a dedicated slot.

Filtered Media is Crucial: The Silicon Carbide seal faces are incredibly hard but can be damaged by abrasive contaminants. Always use coolant that has filtration at 50 microns or better. This filtration level removes harmful particles from the coolant. As a result, the seals stay clean and well-protected. Clean coolant reduces friction and prevents early seal wear. Therefore, the rotary union operates with a longer service life. In addition, good filtration helps keep the system leak-free.

Correct Hose Connection: Use a flexible hose for the housing connection. The hose accommodates any slight misalignment. It prevents pipe strain from reaching the union. This approach protects the rotary union from stress and potential damage.

Following these guidelines will ensure your Deublin union delivers the world-class performance and reliability it is known for.

FAQ

Q1: Is this rotary union interchangeable with the original Deublin 1129-036-301?

A1: Yes, it is a direct OEM replacement with identical dimensions and specifications.

Q2: Can it handle both coolant and air?

A2: Yes, the dual-passage design supports simultaneous supply and return of coolant and air.

Q3: What industries typically use this model?

A3: CNC machining, printing, steel, paper, textiles, and automation industries.

Q4: How does it compare to OEM Deublin products?

A4: Performance is equivalent, but it is more cost-effective and available with shorter lead times.

Q5: What is the maximum speed and pressure rating?

A5: Up to 3,000 RPM and 150 PSI, depending on the medium.

Customer Testimonials

⭐️⭐️⭐️⭐️⭐️ – “Perfect drop-in replacement for our CNC machine spindle. Installed quickly and works flawlessly. Great value compared to OEM pricing.”

⭐️⭐️⭐️⭐️⭐️ – “We’ve used this rotary union for our printing press. Excellent quality, stable performance, and no leakage issues.”

⭐️⭐️⭐️⭐️⭐️ – “High durability and fast shipping. This Deublin 1129-036-301 alternative exceeded our expectations.”

Conclusion

The Deublin 1129-036-301 Rotary Union Replacement is the ideal choice for companies seeking reliable, cost-effective solutions for fluid and air transfer in rotating equipment. With OEM-level performance, durable construction, and affordability, it ensures stable operation in demanding industrial environments while reducing maintenance costs and downtime.

Upgrade your equipment with a precision-engineered rotary joint that delivers both performance and value—choose the Deublin 1129-036-301 alternative today.