Deublin 2620-201-252

- Part Number: 2620-201-252

- Maximum Pressure: 140 bar (2030 psi)

- Maximum Speed:Up to 7000 RPM

- Media Compatibility: Water, oil, air, coolant

- Seal Material:Silicon carbide

- Dimensions: Customizable upon request

Description

Key Features

Key Features

Versatile Media Transfer: Capable of transferring a variety of fluids including water, oil, air, and coolant, the Deublin 2620-220-252 supports applications requiring Minimum Quantity Lubrication (MQL) and cutting oils.

High Pressure and Speed: Designed to handle pressures up to 140 bar (2030 psi) and spindle speeds of up to 7000 RPM, this rotary union ensures optimal performance in demanding environments.

Advanced Seal Technology: Utilizes micro-lapped seals made from high-grade materials such as silicon carbide, providing superior resistance to wear and heat accumulation. This technology minimizes seal wear, enhancing the longevity and reliability of the union.

Balanced Mechanical Design: The balanced mechanical seals reduce thrust loads on the spindle, further extending the service life of the rotary union while ensuring smooth operation.

Deublin 2620-201-252 Rotary Union

The Deublin 2620-220-252 Rotary Union is a high-performance mechanical device designed to efficiently transfer fluids and media in rotating applications. Renowned for its reliability and durability, this rotary union is ideal for various industrial settings, particularly in machine tools and machining centers.

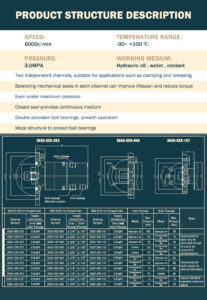

Technical Specifications of Deublin 2620-201-252 Rotary Union

Technical Specifications of Deublin 2620-201-252 Rotary Union

Part Number: 2620-201-252

Maximum Pressure: 140 bar (2030 psi)

Maximum Speed:Up to 7000 RPM

Media Compatibility: Water, oil, air, coolant

Seal Material:Silicon carbide

Dimensions: Customizable upon request

The Deublin 2620-220-252 Rotary Union offers several key benefits that significantly enhance machining applications. Here are the primary advantages:

The Deublin 2620-220-252 Rotary Union offers several key benefits that significantly enhance machining applications. Here are the primary advantages:

Enhanced Tool Life

The rotary union facilitates efficient heat dissipation during machining processes, which is crucial for extending the lifespan of cutting tools. By maintaining optimal temperatures, it reduces wear and tear on tools, leading to lower replacement costs and improved overall productivity.

Improved Machining Quality

Uniform coolant flow provided by the Deublin rotary union prevents thermal distortion during machining. This consistency in coolant delivery ensures high-quality machined components with precise tolerances, minimizing defects and enhancing the final product’s quality.

Increased Productivity

With its ability to maintain uninterrupted operations, the Deublin 2620-220-252 rotary union minimizes downtime associated with coolant supply issues. This reliability leads to enhanced productivity in machining environments, allowing for longer operational periods without interruptions.

Versatile Media Compatibility

The rotary union is designed to handle various media types, including water-based coolants, oils, and air. This versatility allows it to be used across different machining applications and processes, providing a flexible solution for manufacturers.

High Pressure and Speed Capabilities

The Deublin rotary union can operate under high pressures (up to 140 bar) and speeds (up to 7000 RPM), making it suitable for demanding industrial applications. This capability ensures that it can meet the rigorous requirements of modern machining operations.

Advanced Seal Technology

Utilizing balanced mechanical seals made from high-grade materials like silicon carbide, the rotary union minimizes seal wear and enhances longevity. The design reduces thrust loads on the spindle, contributing to smoother operation and longer service life.

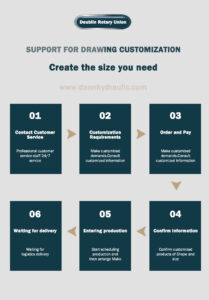

Customization Options

Deublin offers customization of the rotary union interface to fit specific machine requirements, including hose connections and rotor threading. This adaptability ensures that users can integrate the rotary union seamlessly into their existing systems for optimal performance.

In summary, the Deublin 2620-220-252 Rotary Union stands out as a vital component in machining applications, delivering enhanced tool life, improved quality, increased productivity, and versatile performance tailored to meet diverse industrial needs. FAQ of deublin 2620-201-252 Rotary Union

FAQ of deublin 2620-201-252 Rotary Union

What is the Deublin 2620-220-252 Rotary Union used for?

The Deublin 2620-220-252 Rotary Union is primarily used for transferring fluids such as coolant and air in rotating applications, particularly in machine tools and machining centers. Its design allows for efficient media transfer during high-speed operations.

What are the key features of the Deublin 2620-220-252?

Key features include:Dual Independent Passages: Allows simultaneous clamping and unclamping operations.

Balanced Mechanical Seals: Provide long life and reduced torque even under maximum pressure.

Labyrinth System: Protects ball bearings, ensuring smooth operation.

High Pressure and Temperature Ratings: Supports pressures up to 140 bar (2030 psi) and temperatures up to 71°C (160°F) for both coolant and air applications.

How does the seal technology work in the Deublin 2620-220-252?

The rotary union employs balanced mechanical seals made from high-grade materials, including silicon carbide. This design minimizes thrust loads on the spindle and reduces wear, allowing for smooth operation even at high speeds and pressures.

What are the maximum operating specifications for the Deublin 2620-220-252?

The maximum operating specifications are:Coolant Maximum Pressure: 70 bar (1015 psi)

Air Maximum Pressure: 10 bar (145 psi);Coolant Maximum Flow Rate: 18.2 GPM (69 l/min)

Air Maximum Flow Rate: 74.2 CFM (2100 l/min).

In what industries is the Deublin 2620-220-252 commonly used?

This rotary union is commonly used in industries such as:Manufacturing: For CNC machines and lathes;Automotive: In machining operations requiring precise fluid delivery;Aerospace: For applications where high-speed machining is essential.

What maintenance does the Deublin 2620-220-252 require?

Regular inspection of seals and bearings is recommended to ensure optimal performance. Although designed for durability, periodic checks can help identify wear early, preventing operational issues. Replacement kits are available for seals to facilitate maintenance.

How does the design of the Deublin 2620-220-252 contribute to its longevity?

The balanced mechanical seal design minimizes friction and wear by reducing thrust loads on the spindle. Additionally, its robust construction with high-quality materials enhances resistance to heat and pressure, contributing to a longer service life.

Can the Deublin 2620-220-252 be customized for specific applications?

Yes, Deublin offers customization options for the rotary union to fit specific machine requirements, including different rotor connections and housing configurations, ensuring it meets unique operational needs.

What advantages of using a dual passage rotary union like the Deublin 2620-220-252?

The dual passage design allows for simultaneous fluid transfer for different functions, such as cooling and lubrication or clamping and unclamping, improving efficiency in machining processes by reducing cycle times.

What should users consider when selecting rotary union like the Deublin 2620-220-252?

Media Type: Ensure compatibility with fluids being used.

Pressure Requirements: Confirm that operating pressures fall within specified limits.

Speed Capabilities: Match the rotary union’s speed ratings with machine specifications.

These considerations will help ensure optimal performance and longevity of the rotary union in their specific applications.