Deublin 55/57 Series Rotary Union Deublin Rotating Union

Original price was: $80.00.$60.00Current price is: $60.00.

- Size: 1/4″ – 4″

- Max. speed: 3000r/min

- Max. Temperature: 80℃/120℃

- Max. Pressure: 1.6Mpa

- Connections: Thread

- Standard: METRIC,NPT,BSPT

- Applicable medium: coolant water/hot water/cold oil/air

- Hosing material: brass

Description

DEUBLIN 55 57 Series Rotary Union Deublin Rotating Union

Deublin 55 series rotary union is mainly designed for cooling systems, It has the advantages of small size, light weight, small friction resistance torque, etc. Ball bearing ensures the coaxiality of the rotating tube. The friction pair material has various material pairs, such as impregnated graphite, bronze, silicon carbide, tungsten carbide, etc., to choose from according to different media environments, which are enough to resist the influence of rust scaling and other impurities on the sealing surface. After finishing, the sealing surface is like a mirror, the sealing is more reliable, the service life is longer, and it is widely used.

55/57 Series rotary union is mainly designed for the cooling system. It has the advantages of small volume, light weight, small friction resistance moment, ball bearing to ensure the coax of the tube, friction pair materials according to different media environment, impregnated graphite, bronze silicon carbide, tungsten carbide and other choice materials, enough to resist rust scale and other impurities on the sealing surface. After finishing the sealing surface, the surface is like a mirror, sealing is more reliable. The service life is longer, and the application is more expansive. The 55/57 Series Rotary Union is engineered to deliver exceptional performance and reliability in various industrial applications. This rotary union is ideal for transferring fluids and gases while ensuring minimal leakage and maximum efficiency.

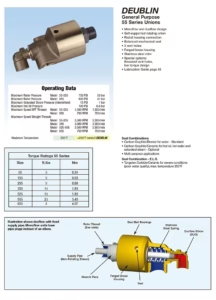

Universal 55 Series deublin rotating union

DN10-50;

Single and dual channel designs;

Self-supporting swivel;

Radial housing connection;

Balanced mechanical seal;

3 leak ports;

Forged brass housing;

Stainless steel rotor;

Threaded leak port;

Splash-proof bearings;

Nickel plated and/or low torque design.

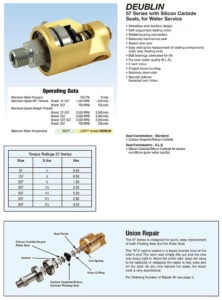

Seal combinations – standard

- Graphite/copper, optional for water applications;

- Graphite/ceramic, hot oil, hot water, and saturated steam;

- Versatile applications;

- Seal combinations – E.L.S (Extended Life Seal);

- Tungsten carbide/ceramic, for harsh conditions (poor quality water) up to 90 degrees Celsius.

| Item | Value |

|---|---|

| Model | 3/8-2 inch |

| Pressure | ≤30kg |

| Speed | n≤3500RPM |

| Temperature | 80℃ (Contact customer service for high temperature customization) |

| Applicable medium | Water, hydraulic oil |

Key Features of Deublin 55/57 Series Rotary Union

The Deublin Rotary Union is a high-performance solution designed for fluid transfer in demanding industrial applications. Key features include:

1. Versatile Design

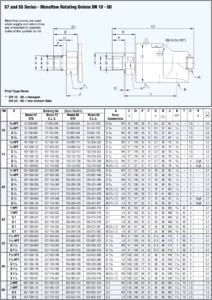

Small size, light weight, low friction torque; Single-channel and dual-channel design with fixed supply pipe, single-channel spinner with pipe plug instead of elbow, allowing for flexibility in installation depending on the application requirements.

2. High-quality shell

Using imported bearings and seals, Choice of wrought copper shell, light weight, small volume, reliable sealing, and longer working life. The radial connection enhances the ease of integration into existing systems.

3. Balanced Mechanical Sealing

Balanced mechanical seal silicon carbide seals extend service life even under harsh operating conditions. Ensures a leak-proof operation, extending the life of the rotary union and reducing maintenance costs. The rotor seal securely keyed to prevent slippage, enhancing operational reliability.

Adopting plane sealing technology, using impregnated graphite, bronze, tungsten carbide, and other materials to make it more wear-resistant and longer life.

4. Support customization

Support drawing customization, non-standard customization, and customers can customize different types of joints according to their needs. Can issue drawings and process according to customer requirements.

Product Highlights of Deublin 55/57 Series Rotary Union

1. Robust Construction & Material Excellence

Built with stainless steel, brass, or bronze for corrosion resistance and durability, ideal for harsh environments (e.g., high-temperature steam, hot oil, or chemical exposure).

Precision-balanced mechanical seals ensure leak-free performance even at pressures up to 50 bar (55 Series) and speeds up to 3,500 RPM.

2. Versatile Media Compatibility

55 Series: Handles water, hot oil, and general-purpose fluids up to 120°C, suitable for diverse industrial applications.

57 Series: Optimized for water-based media at lower pressures (10 bar) but higher reliability in continuous operations.

3. High-Speed Performance

Engineered for high rotational speeds (3,500 RPM), making them ideal for dynamic machinery like CNC spindles, packaging lines, and textile equipment.

4. Easy Maintenance & Longevity

Modular design allows quick replacement of seals and bearings, minimizing downtime.

Self-supporting rotor structure reduces wear and extends service life.

5. Industry-Specific Certifications

Compliant with ISO standards and ATEX directives, ensuring safety in explosive environments.

Customer Pain Points& Solution Provided by Deublin 55/57 Series

1. Customer Pain Points: Seal Failures

Customers often face premature seal wear due to poor water quality, high pressure, or exceeding operational specifications.

Solutions: Extended Life Sealing (E.L.S.) Technology

The 57 Series features Silicon Carbide/Silicon Carbide seals for severe conditions like poor water quality, ensuring longer operational life.

2. Customer Pain Points: Downtime During Maintenance

Replacing worn-out components can lead to extended machine downtime, impacting productivity.

Solutions: Efficient Maintenance Design

The quick replacement mechanism reduces downtime significantly by allowing on-site repairs without the need for full disassembly.

3. Customer Pain Points: Compatibility Issues

Matching the union with specific machine requirements can be challenging, especially in unique applications.

Solutions: Customizable Configurations

Mono and Duo flow designs cater to diverse industrial fluid transfer needs, ensuring compatibility with various applications.

4. Customer Pain Points: Corrosion in Harsh Environments

Exposure to aggressive media can lead to corrosion and reduced service life of components.

Solutions: Corrosion-Resistant Materials

Stainless steel components in media-contact areas prevent corrosion, even in aggressive environments.

FAQ of Deublin 55/57 Series Rotary Union

Q1: What are the key features of the Deublin 55 series Rotary Union?

A1: The Rotary Union features a mono-flow and duo-flow design, a self-supported structure, and a balanced mechanical seal. It also allows for easy maintenance with quick replacement of sealing components. It has a forged brass housing with a stainless steel rotor for durability.

Q2. What applications are suitable for the Dublin 55 series Rotary Union?

A2: This rotary union is ideal for various industrial applications, including manufacturing, food processing, chemical processing, and the textile industry.

Q3: What is the maximum pressure and temperature rating for these rotary unions?

A3: The 55/57 Series can handle pressures up to 750 PSI(50 bar) and temperatures up to 250°F (121°C). It is suitable for hot water and hot oil applications.

Q4. How does the maintenance process work for the 55/57 Series?

A4: Maintenance is simplified as the worn seals can be easily replaced without needing to remove or re-lap the entire rotor. The seals lift out easily, allowing for quick on-site repairs.

Q5. What materials used in the construction of the 55/57 Series?

A5: The rotary union features a forged brass housing, a stainless steel rotor, and seals made from carbon graphite/silicon carbide, which are suitable for various media, including hot oil and water.

Q6: Can the 55/57 Series Rotary Union used in explosive environments?

A6: Yes, certain models of the 55/57 Series are available with ATEX certification, making them suitable for use in potentially explosive atmospheres.

Q7: What are the differences between monoflow and duoflow designs in this series?

A7: Monoflow unions connect supply and return lines on opposite sides of a cylinder or roll, while duoflow unions connect both lines on one side, allowing for more compact installations.

Conclusion

The Deublin 55/57 Series Rotary Union addresses critical customer pain points by offering durable seals, efficient maintenance solutions, and robust construction tailored for demanding applications. Its innovative features ensure reliability, reduced downtime, and long-term cost savings for industries such as manufacturing, paper production, and steel processing.