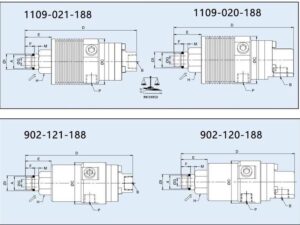

Deublin 902 120 188

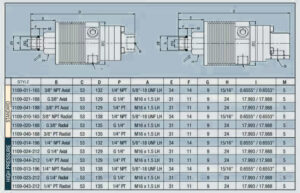

- Model: 902 120 188

- Max Operating Pressure: 145 PSI (10 bar)

- Max Speed: Up to 20,000 RPM

- Max Flow Rate: Up to 4.1 GPM (15 l/min)

- Max Temperature: Up to 70°C

- Housing Material: Anodized aluminum

- Rotor Material: Stainless steel

Description

Key Features

Key Features

Monoflow Design: The Deublin 902 120 188 features a monoflow design that allows for a streamlined flow of coolant, ensuring efficient operation and minimal turbulence.

High-Wear Resistant Seals: Equipped with balanced mechanical seals made from Silicon Carbide, this rotary union is built to withstand harsh conditions, providing exceptional durability and longevity.

Self-Supported Construction: The self-supported design enhances stability during operation, reducing wear on components and extending service life.

High-Speed Capability: Capable of operating at speeds up to 20,000 RPM, this rotary union is ideal for high-speed machining applications where precision is critical.

Effective Labyrinth System: The integrated labyrinth system protects the bearings from contamination, ensuring smooth operation and reducing maintenance needs.

Deublin 902 120 188 Rotary Union: Product Overview

The Deublin 902 120 188 Rotary Union is a state-of-the-art solution designed for efficient fluid transfer in high-performance applications. Engineered with precision and durability in mind, this rotary union excels in environments where reliable coolant delivery is essential, such as in machine tools and industrial machinery.

Technical Specifications of Deublin 902 120 188 Rotary Union

Technical Specifications of Deublin 902 120 188 Rotary Union

Part Number: 902 120 188

Part Number: 902 120 188

Max Operating Pressure: 145 PSI (10 bar)

Max Speed: Up to 20,000 RPM

Max Flow Rate: Up to 4.1 GPM (15 l/min)

Max Temperature: Up to 70°C

Housing Material: Anodized aluminum

Rotor Material: Stainless steel

Maintenance Requirements for Deublin 902 120 188 Rotary Union

Regular Inspection: Periodically inspect the rotary union for any signs of wear or damage, particularly focusing on the mechanical seals and bearings. Look for leaks or unusual noises during operation.

Lubrication: Ensure that the bearings are adequately lubricated. The Deublin rotary unions are designed with deep groove radial ball bearings that require minimal maintenance, but it’s essential to check for proper lubrication regularly.

Drainage Management: Ensure that the drain hose is installed with a continuous downward slope to facilitate proper drainage. This prevents fluid accumulation that could lead to seal damage or operational issues.

Cleanliness: Maintain cleanliness around the rotary union. Debris and contaminants can affect performance and lead to premature wear. Clean the union and surrounding areas regularly to prevent buildup.

Monitor Operating Conditions: Keep track of operating pressure and temperature, ensuring they remain within specified limits (maximum pressure of 145 PSI and temperature up to 70°C). Avoid exceeding these limits to prevent damage.

Check Connections: Ensure that all connections (supply and drain hoses) are secure and free from leaks. Loose connections can lead to fluid loss and operational inefficiencies.

Seal Replacement: The balanced mechanical seals made from silicon carbide are designed for long life; however, they may need replacement if significant wear is detected. Follow Deublin’s guidelines for replacing seals when necessary.

Pop-Off Technology: Take advantage of the Pop-Off™ technology that allows unlimited dry running without media pressure during tool changes. Ensure that the seals separate correctly during unpressurized operation to avoid wear.

Professional Servicing: For any major repairs or if you notice persistent issues, contact Deublin or an authorized service provider for professional assistance. Using only Deublin spare parts is recommended for any replacements.

Documentation and Compliance: Keep a maintenance log documenting inspections, repairs, and replacements performed on the rotary union. This helps in tracking performance over time and ensuring compliance with best practices. FAQ of deublin 902 120 188

FAQ of deublin 902 120 188

What is the Deublin 902 120 188 Rotary Union?

The Deublin 902 120 188 is a rotary union designed for the efficient transfer of coolant or Minimum Quantity Lubrication (MQL). It features Pop-Off™ technology, allowing for unlimited dry running without media pressure, making it ideal for high-speed machining applications.

How does Pop-Off™ technology work?

Pop-Off™ technology allows the mechanical seals to separate during pressureless operation, preventing wear during tool changes and enabling dry running without coolant. This feature enhances the rotary union’s durability and reduces maintenance needs.

What materials are used in the construction of the Deublin 902 120 188?

The rotary union features an anodized aluminum housing that resists corrosion, a stainless steel rotor for strength, and balanced mechanical seals made from silicon carbide to ensure long life even under challenging conditions.

What applications is the Deublin 902 120 188 suitable for?

It is widely used in various industrial applications, including:CNC machine tools for coolant delivery,Textile manufacturing machinery,Automotive assembly lines where precise lubrication.

How does the Deublin 902 120 188 prevent contamination?

The rotary union features an effective labyrinth system and large vents designed to protect ball bearings from contamination, ensuring smooth operation and reducing wear over time.

Can the Deublin 902 120 188 be used for dry running?

Yes, thanks to its Pop-Off™ technology, Deublin can operate without coolant during tool changes or in dry run conditions, making it versatile for various machining processes.

What are the benefits of using the Deublin 902 120 188 Rotary Union?

Benefits include enhanced operational efficiency due to reliable coolant flow, reduced downtime from low maintenance needs, versatility across multiple industries, and cost-effectiveness through its long service life and durability.