Deublin 902 121 188

- Part Number: 902 121 188

- Max Coolant Pressure: 10 bar

- Max Speed: 20,000 RPM

- Max Flow Rate: 15 l/min

- Connection Type: Axial and Radial

- Material: Anodized Aluminum & SS

Description

Key Features

Key Features

Single Passage Design: Specifically designed for coolant or MQL, allowing for efficient fluid transfer without obstruction.

Pop-Off™ Technology: This innovative feature enables unlimited dry running without media pressure, making it ideal for applications where fluid presence may not always be guaranteed.

Full-Flow Design: The rotary union boasts a full-flow design that prevents the trapping of swarf or debris, ensuring uninterrupted operation.

High-Quality Bearings: Equipped with deep groove radial ball bearings, the 902-121-188 guarantees smooth operation and longevity, even under heavy loads.

Robust Mechanical Seals: Constructed with balanced mechanical seals made from silicon carbide, this rotary union is built to withstand challenging operational conditions while minimizing wear and tear.

Corrosion-Resistant Housing: The anodized aluminum housing not only enhances durability but also protects against corrosion, extending the service life of the unit.

Deublin 902-121-188 Rotary Union: Product Overview

The Deublin 902-121-188 Rotary Union is a cutting-edge solution designed to meet the demanding needs of modern industrial applications. Engineered for seamless transfer of coolant and Minimum Quantity Lubrication (MQL), this rotary union ensures efficient operation in various machinery, enhancing productivity and reducing downtime.

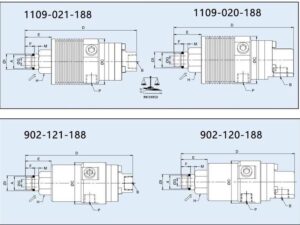

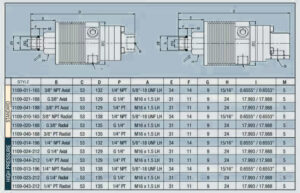

Technical Specifications of Deublin 902 121 188 Rotary Union

Technical Specifications of Deublin 902 121 188 Rotary Union

Part Number: 902 121 188

Part Number: 902 121 188

Max Coolant Pressure: 10 bar

Max Speed: 20,000 RPM

Max Flow Rate: 15 l/min

Connection Type: Axial and Radial

Material: Anodized Aluminum & SS

Benefits of Using the Deublin 902-121-188 Rotary Union

Increased Efficiency: By allowing continuous operation without the need for frequent stops, this rotary union enhances overall productivity in manufacturing processes.

Reduced Maintenance Costs: The robust design minimizes wear and tear on machinery components, leading to lower maintenance requirements and extended equipment lifespan.

Versatile Applications: Ideal for a variety of industries including automotive, aerospace, and manufacturing, the Deublin rotary union adapts to different operational needs seamlessly.

Enhanced Safety: With its reliable sealing technology, the risk of leaks is significantly reduced, ensuring safer working environments and compliance with environmental standards.

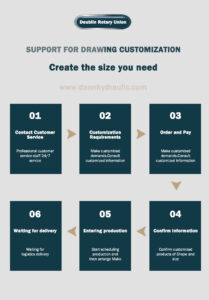

Customizable Solutions: The flexibility in design allows for tailored configurations to meet specific application requirements, making it a versatile choice for diverse industrial settings.

Key Industries Benefiting from Deublin 902-121-188 Rotary Union

Machine Tool Industry:

Applications: The rotary union is extensively used in CNC machines, EDM (Electrical Discharge Machining), and multi-spindle transfer machines.

Benefits: It allows for effective coolant delivery, enhancing tool life and improving machining precision. The ability to operate at high speeds (up to 24,000 RPM) makes it ideal for demanding applications in this sector.

Automotive Manufacturing

Applications: Commonly found in automotive production lines for machining and assembly processes.

Benefits: The rotary union’s design supports high flow rates and pressures, crucial for maintaining optimal cooling during high-speed operations, thereby ensuring efficiency and reliability in production environments.

Aerospace Industry

Applications: Used in manufacturing components that require precise machining with minimal thermal distortion.

Benefits: The Deublin rotary union provides consistent coolant flow, essential for maintaining the integrity of aerospace components during machining processes.

Robotics and Automation

Applications: Integrated into robotic arms and automated systems where fluid transfer is necessary.

Benefits: Its compact design and ability to handle dry running conditions make it suitable for applications where space is limited, while still providing reliable performance under varying operational conditions.

Textile Machinery

Applications: Employed in machines that require lubrication or cooling during fabric processing.

Benefits: The rotary union ensures continuous operation without interruptions, which is critical for maintaining production efficiency in textile manufacturing.

Food and Beverage Processing

Applications: Used in equipment that requires sanitary fluid transfer, such as cooling systems in food processing machinery.

Benefits: Its corrosion-resistant materials ensure compliance with hygiene standards while providing reliable operation under pressure. FAQ of deublin 902 121 188

FAQ of deublin 902 121 188

What is the Deublin 902-121-188 Rotary Union?

The Deublin 902-121-188 is a rotary union designed for single passage applications, specifically for coolant or Minimum Quantity Lubrication (MQL). It features Pop-Off™ technology, allowing for unlimited dry running without media pressure, making it ideal for various industrial applications.

What industries commonly use the Deublin 902-121-188?

Industries that benefit from this rotary union include:Machine Tool Manufacturing,Automotive Production,Aerospace Engineering,Robotics and Automation,Food and Beverage Processing.

What are the maximum operational specifications of the Deublin 902-121-188?

The rotary union can handle: Max Coolant Pressure: 69 bar (1000 psi),Max Flow Rate for Coolant: 82 l/min (21.7 GPM), Max Flow Rate for MQL: 2040 l/min (72.1 CFM),Max Temperature: Up to 71 °C (160 °F) for both coolant and MQL applications.

How does Pop-Off™ technology enhance performance?

Pop-Off™ technology allows the rotary union to operate without media pressure, which means it can run dry indefinitely without damage. This feature is particularly beneficial in applications where fluid presence may not always be assured, thus enhancing versatility and reducing maintenance needs.

What maintenance considerations should be noted?

To ensure longevity, it is crucial to maintain cleanliness during installation and storage, as well as adhere to specified tolerances for spindle connections. Regular checks on seals and bearings will help prevent premature wear and ensure optimal performance.

How does the design prevent contamination?

The full-flow design of the Deublin 902-121-188 minimizes obstructions that could trap swarf or debris, which helps maintain fluid purity and prevents contamination in sensitive applications like machining and food processing.

What is the installation process like?

The rotary union features a threaded rotor connection for easy installation, ensuring a secure fit. Proper alignment with the spindle end is necessary to prevent vibration or wobble during operation, which can shorten service life.

Can the Deublin 902-121-188 be used in high-speed applications?

Yes, it is designed to operate at high speeds (up to 20,000 RPM), making it suitable for demanding environments such as CNC machining where precision and efficiency are critical.