Deublin 902-141-192 Rotary Union Price

Original price was: $130.00.$116.00Current price is: $116.00.

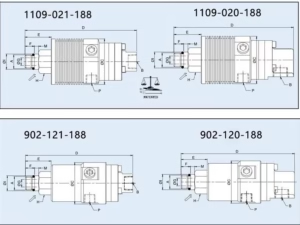

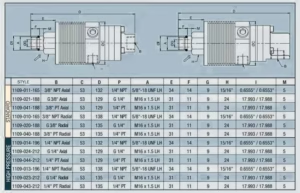

- Part Number: 902-141-192

- Max Coolant Pressure: 10 bar (145 psi)

- Max Speed:20,000 RPM

- Max Flow Rate:15 l/min (3.96 GPM)

- Max Temperature:70 °C (158 °F)

- Rotor Connection Type: Axial and Radial

Description

The Deublin 902-141-192 Rotary Union is a precision-engineered solution designed to facilitate seamless fluid transfer between stationary and rotating components in industrial machinery. Engineered by Deublin, a globally recognized leader in rotary union technology, this model combines advanced materials, innovative sealing mechanisms, and robust construction to deliver unmatched performance in high-speed, high-pressure applications. Ideal for coolant supply, hydraulic systems, and industrial automation, the 902-141-192 ensures leak-free operation, extended service life, and compatibility with diverse media types.

Key Features of Deublin 902-141-192 Rotary Union

💧 Monoflow Design

Single-passage system for efficient coolant or MQL delivery, optimizing fluid flow.

⚙️ Self-Supported Construction

Simplifies installation with no extra support needed, reducing system complexity.

🛡️ High-Wear Resistant Seals

Balanced mechanical seals made of silicon carbide for exceptional durability under tough conditions.

🎯 Robust Bearings

High-precision angular contact ball bearings (X-pattern) ensure stability and smooth, high-speed rotation.

🏗️ Corrosion-Resistant Housing

Anodized aluminum housing protects against corrosion and wear, extending service life.

Technical Specifications

| Parameter | Value |

|---|---|

| Max Pressure | 10 bar (145 psi) |

| Max Temperature | -30°C to +80°C (-22°F to 176°F) |

| Flow Rate | 15 L/min (3.96 GPM) |

| Rotor Connection | M16x1.5 LH with 18mm pilot |

| Housing Material | Anodized Aluminum |

| Seal Material | Silicon Carbide |

Application of Deublin 902-141-192 Rotary Union

🛠️ Machine Tool Manufacturing

Applications: CNC machines, machining centers, transfer lines.

🚗 Automotive Industry

Applications: Assembly lines, machining of automotive components.

✈️ Aerospace Engineering

Applications: Machining and assembly of aircraft components.

🤖 Robotics & Automation

Applications: Integrated in robotic arms and automated fluid transfer systems.

🍽️ Food & Beverage Processing

Applications: Sanitary cooling systems in food processing equipment.

🧵 Textile Machinery

Applications: Lubrication and cooling in fabric processing machines.

🏭 Plastics & Injection Molding

Applications: Cooling systems in injection molding machines.

🔩 Metalworking

Applications: Grinding, milling, and other metalworking processes.

🚜 Construction Equipment

Applications: Hydraulic systems in heavy construction machinery.

⚓ Marine Applications

Applications: Cooling systems in shipbuilding and maintenance.

FAQ of Deublin 902-141-192 Rotary Union

FAQ of Deublin 902-141-192 Rotary Union

What is the Deublin 902-141-192 Rotary Union?

It is a rotary union design for the efficient transfer of coolant and Minimum Quantity Lubrication (MQL). It features a single passage design and is equipped with Pop-Off™ technology, allowing for unlimited dry running without media pressure, making it ideal for various industrial applications.

What materials used in the construction of the Deublin 902-141-192?

The rotary union features an anodized aluminum housing that resists corrosion, along with balanced mechanical seals made from silicon carbide, which provide longevity and reliability even under challenging operating conditions.

What industries commonly use the Deublin 902-141-192?

Industries that benefit from this rotary union include: Machine Tool Manufacturing, Automotive Production, Aerospace Engineering, Robotics and Automation, and Food and Beverage Processing.

What are the installation requirements for the Deublin 902-141-192?

The rotary union has a threaded rotor connection (M16x1.5 LH) and a housing connection of 3/8″-19 PT, making installation straightforward. Proper alignment with the spindle is crucial to avoid vibration during operation.

How does the design prevent contamination?

The full-flow design of 902-141-192 minimizes obstructions that could trap debris or swarf, ensuring a clean fluid path and preventing contamination in sensitive applications like machining.

What maintenance is required for the Deublin rotary union?

Regular maintenance includes checking seals and bearings for wear, ensuring cleanliness during installation, and adhering to specified tolerances for spindle connections to maintain optimal performance and extend service life.

Is the Deublin 902-141-192 Rotary Union suitable for high-speed applications?

Yes, it is designed to operate at high speeds (up to 20,000 RPM), making it suitable for demanding environments such as CNC machining, where precision cooling is critical.