Stainless Steel Rotary Union

Original price was: $35.00.$30.00Current price is: $30.00.

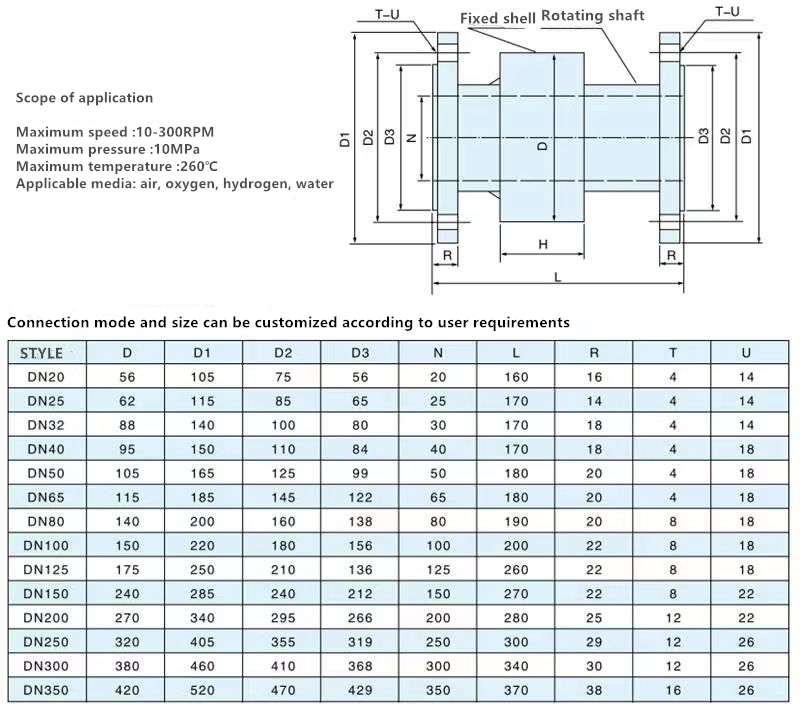

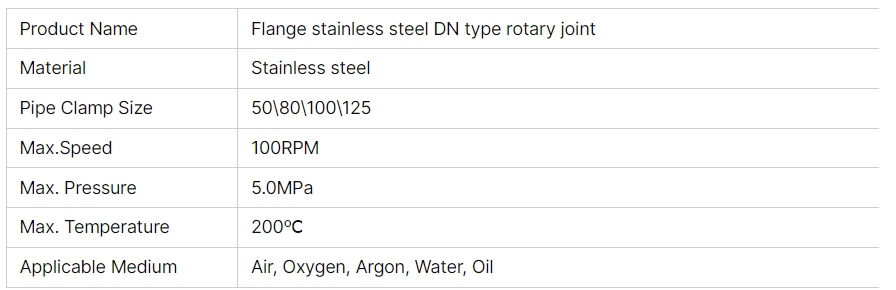

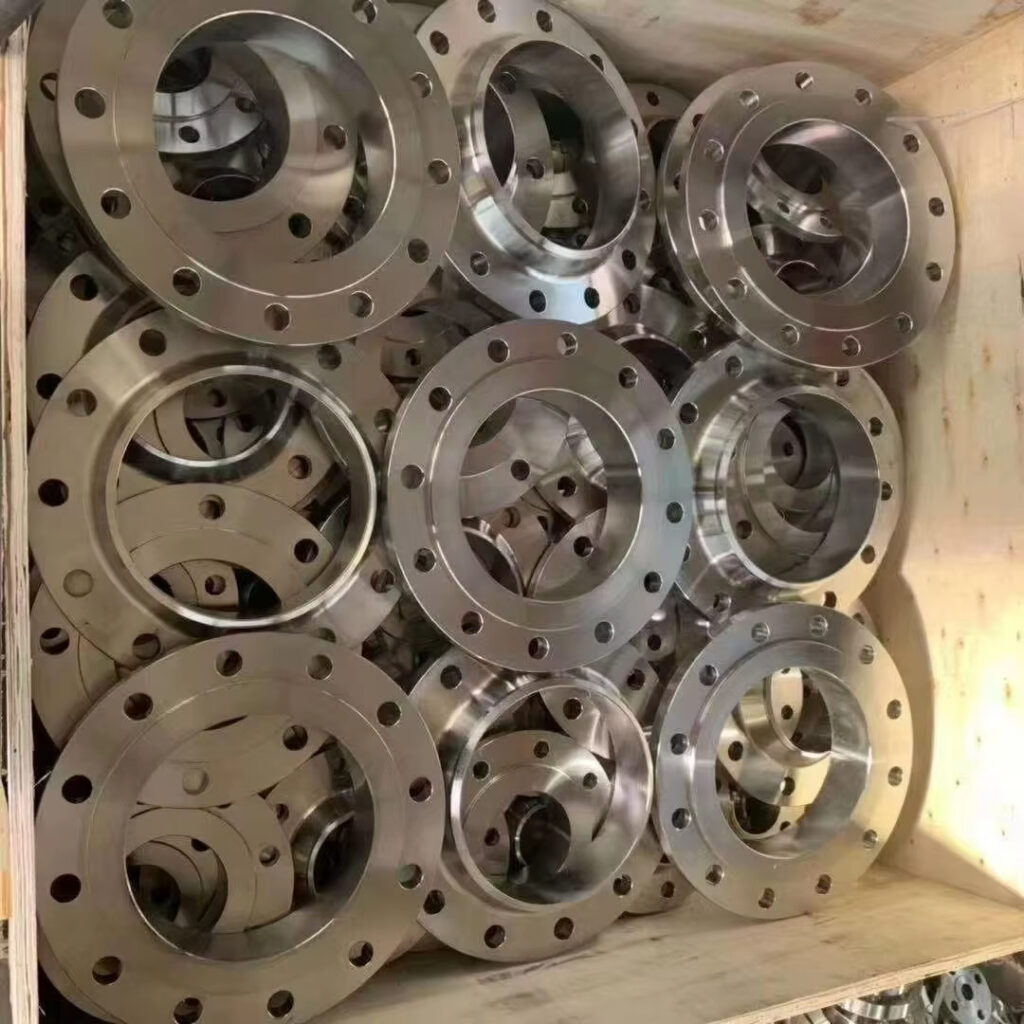

- Product size: from DN20 to DN350

- Maximum pressure: 20 MPa,

- Maximum temperature: 300℃,

- Rotation speed: ≤50 rpm,

- Applicable media: water, steam, oil, air;

- Main material: stainless steel or carbon steel

Description

Structural features:Specially used for rigid pipe connection, reciprocating or low-speed rotation, our company adopts two structures: bearing type and ball type. The sealing material uses PTFE to achieve better sealing and wear resistance and increase the service life of the joint.

Structural features:Specially used for rigid pipe connection, reciprocating or low-speed rotation, our company adopts two structures: bearing type and ball type. The sealing material uses PTFE to achieve better sealing and wear resistance and increase the service life of the joint.

Universal Swivel Rotary Union Dn Type stainless steel Swivel Joint Rotary Union Flat Flange Connection

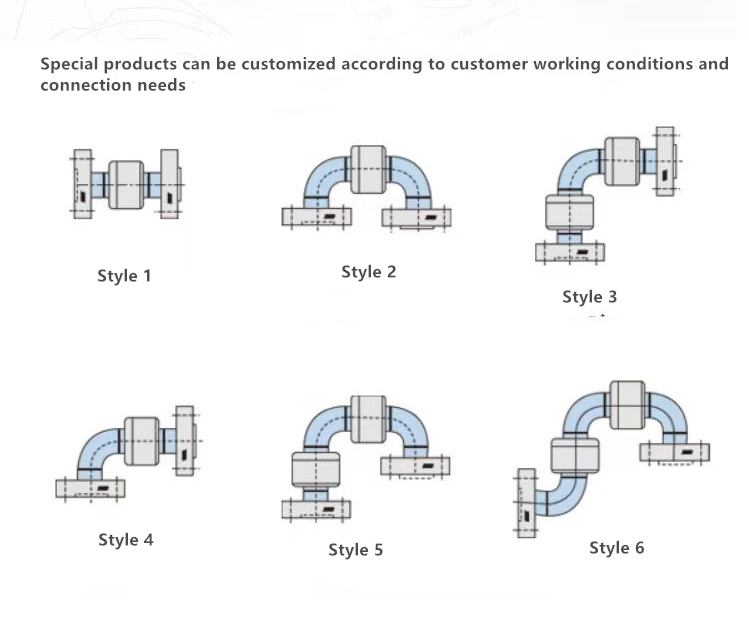

DN Type Rotary Union specially used for rigid pipe connection, reciprocating or low-speed rotation,our company adopts two structures: bearing type and ball type. The sealing material uses PTFE to achieve better sealing and wear resistance and increase the service life of the joint.

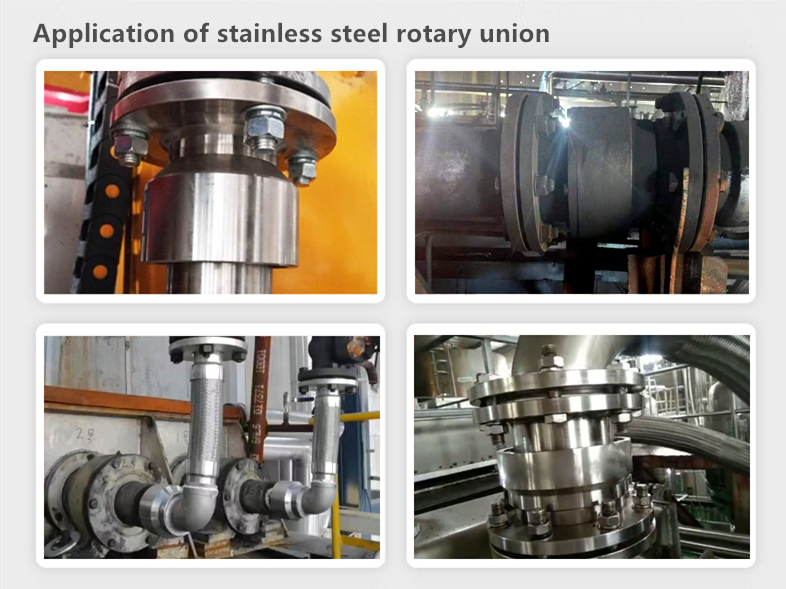

The internal structure of DN Type Stainless Steel Rotary Union is directly supported by high-precision bearings for reciprocating or low-speed rotation, flexible rotation, strong support ability, the movable joint with imported seals used to dredging fluid media between steel pipes is widely used in metallurgy, petrochemical, shipbuilding, paper and other industrial fields.

The internal structure of DN Type Stainless Steel Rotary Union is directly supported by high-precision bearings for reciprocating or low-speed rotation, flexible rotation, strong support ability, the movable joint with imported seals used to dredging fluid media between steel pipes is widely used in metallurgy, petrochemical, shipbuilding, paper and other industrial fields.

FAQ OF DN Type Stainless Steel Rotary Union

FAQ OF DN Type Stainless Steel Rotary Union

Q1: What is a stainless steel rotary union?

A1: A stainless steel rotary union is a mechanical device that allows the transfer of fluids between a stationary inlet and a rotating outlet while maintaining a seal. It is commonly used in applications requiring durability and resistance to corrosion, making it ideal for industries such as food processing, pharmaceuticals, and manufacturing.

Q2: What are the applications of stainless steel rotary unions?

A2: Stainless steel rotary unions are used in various industries including food and beverage, pharmaceuticals, printing, and plastics. They facilitate processes such as cooling, heating, and fluid transfer in machinery like extruders, mixers and printing presses.

Q3: How do I choose the right stainless steel rotary union for my application?

A3: When selecting a stainless steel rotary union, consider factors such as the type of fluid being transferred, pressure and temperature ratings, connection types, and the specific requirements of your machinery. Consulting with manufacturers can also help ensure compatibility.

Q4: What are the advantages of using stainless steel for rotary unions?

A4: Stainless steel offers several benefits for rotary unions including high corrosion resistance, durability under extreme conditions, and suitability for sanitary applications. This makes it an excellent choice for industries where hygiene and material integrity are critical.

Q5: What maintenance is required for stainless steel rotary unions?

A5: Regular maintenance is essential to prevent issues like leakage or blockage. This includes inspecting seals, checking for wear and tear, and ensuring proper alignment during installation to avoid side loading.

Q6: Can stainless steel rotary unions be customized?

A6: Yes, many manufacturers offer customization options for stainless steel rotary unions to meet specific operational needs. This can include modifications in size, port locations, or additional features tailored to particular applications.

Q7: What is the typical lifespan of a stainless steel rotary union?

A7: The lifespan of a stainless steel rotary union varies based on usage conditions such as speed, pressure, and maintenance practices. Generally, with proper care and appropriate application settings, they can last several years before requiring replacement or refurbishment.

Q8: Are there different types of seals used in stainless steel rotary unions?

A8: Yes, stainless steel rotary unions can utilize various sealing technologies including mechanical seals, O-rings, and hydrostatic seals. The choice of seal depends on factors like fluid type and operating conditions.

Q9: What are common problems associated with stainless steel rotary unions?

A9: Common issues include leakage due to worn seals, blockages from debris in the fluid media, and premature wear from excessive speed or improper installation. Regular inspections can help mitigate these problems.

Q10: Where can I purchase stainless steel rotary unions?

A10: Stainless steel rotary unions can be purchased from specialized manufacturers or suppliers that focus on fluid transfer equipment. We can provide various models and customization options depending on your needs.