Duoflow Male Steam Dryer Machine Rotary Union

Original price was: $35.00.$28.00Current price is: $28.00.

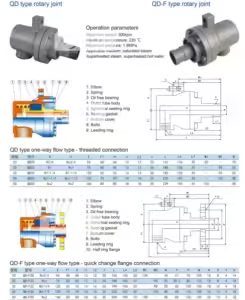

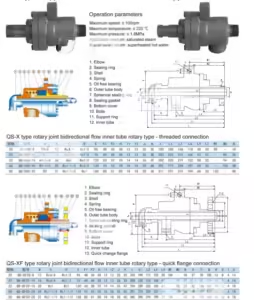

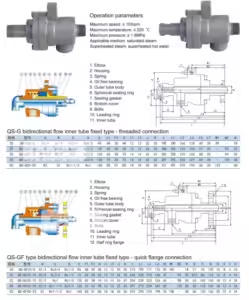

- Maximum speed of use: 120RPM

- Maximum pressure: 1.8MPA

- Maximum temperature :220℃

- Applicable media: water, steam, hot water, etc.

Description

Product Overview: Duoflow Male Steam Dryer Machine Rotary Union

Introducing our state-of-the-art Duoflow Male Steam Dryer Machine Rotary Union, designed to enhance the efficiency and reliability of your drying processes. This innovative product ensures seamless fluid transfer while maintaining optimal performance in high-temperature environments.

Key Features of Duoflow Male Steam Dryer Machine Rotary Union

Robust Design: Engineered with a rigid mounting and protective PTFE sole, our rotary union is positioned closer to the dryer shell, facilitating effective condensate removal. This design minimizes differential pressure and blow-through, ensuring consistent operation even at high speeds.

High Performance: Capable of handling steam pressures up to 150 PSI and hot oil pressures of 100 PSI, our rotary union supports speeds up to 400 MPM (1300 FPM). This makes it ideal for various industrial applications, including pulp and paper processing, where maintaining moisture profiles is critical.

Versatile Applications: Suitable for a wide range of media types—steam, water, thermal oil, and hydraulic fluids—the rotary union can be customized with multiple passages to manage different fluids simultaneously. This versatility is essential in industries such as food and beverage, aerospace, and manufacturing.

Enhanced Efficiency: The unique design promotes better heat transfer by maintaining a turbulent condensate layer around the dryer’s circumference. This ensures uniform temperature distribution, significantly improving the moisture profile of the dried product.

FAQ

What are the benefits of using a Rotary Union in dryer machines?

Rotary unions enhance efficiency by providing a reliable seal for steam, hot oil, and water applications, minimizing leaks and ensuring consistent fluid transfer. This leads to improved drying performance, energy savings, and reduced maintenance costs due to their robust design and minimal wear and tear.

How do rotary unions impact the energy efficiency of dryer machines?

Rotary unions contribute to energy efficiency by optimizing steam transmission and reducing operational costs. By eliminating steam loss and minimizing differential pressure, they help maintain consistent temperatures and reduce energy consumption in drying processes.

What industries benefit most from rotary dryers equipped with rotary unions?

Industries such as food processing, pharmaceuticals, mining, and agriculture benefit significantly from rotary dryers with rotary unions. These sectors require uniform drying, high throughput, and energy-efficient operations for bulk materials like grains, chemicals, and biomass.

How does the design of rotary unions prevent flooding in dryer machines?

The design of rotary unions minimizes flooding by ensuring a positive seal that prevents backflow of steam or fluids. This is particularly important in high-speed applications where maintaining pressure balance is critical .

What customization options available for rotary unions used in dryers?

Rotary unions can be customized in terms of size, material construction and connection types to meet specific application requirements. This adaptability allows tohandle various media types ensuring optimal performance.

What common issues faced with rotary joints in dryer applications?

Common issues include premature wear due to improper installation, which lead to leaks or reduced efficiency. Regular maintenance and adherence to recommended installation practices can mitigate these problems.

Can rotary unions used in high-pressure applications?

Yes, many rotary unions designed to handle high-pressure conditions, making them suitable for applications involving steam or hot oil at significant pressures without compromising performance or safety.

What advancements made in rotary union technology for dryer machines?

Recent advancements focus on enhancing sealing technologies to improve reliability under extreme conditions, as well as integrating smart monitoring systems that provide real-time data on performance metrics, thereby facilitating proactive maintenance.