Dual Passage Rotary Union for Printing Ink

Original price was: $15.00.$12.00Current price is: $12.00.

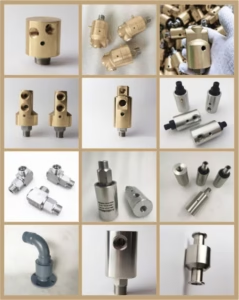

- Material Options: Stainless Steel, Brass, Carbon Steel

- Pressure Rating: Up to 5000 PSI (customizable)

- Temperature Range: -20°C to 200°C (-4°F to 392°F)

- Port Sizes: 1/8” to 2” (custom sizes available)

- Rotation Speed: Up to 1000 RPM (higher speeds available upon request)

Description

The H Series Dual Passage Rotary Union for Printing Ink is a rugged, high-performance rotary coupling designed for modern printing machinery. It delivers continuous, leak-free fluid transfer to rotating print cylinders, enabling a constant supply of ink from stationary pumps to high-speed rollers. Its dual independent channels allow two separate media (e.g., ink and coolant or compressed air) to flow simultaneously, eliminating the need for multiple unions and preventing. Constructed from corrosion-resistant 316L stainless steel with precision-balanced PTFE composite seals, the H Series union is built to withstand demanding press conditions. The result is uniform ink delivery, higher print quality, and minimal maintenance downtime even under high speeds and pressures.

Our Dual Passage Rotary Union is specifically engineered for applications requiring the simultaneous transfer of two independent media, such as air, hydraulic fluid, or vacuum, between stationary and rotating components. Built with precision and using premium-grade materials, this rotary union ensures reliable operation, minimal leakage, and superior durability even under demanding conditions.

Whether you need to transfer compressed air, cooling fluids, or hydraulic oil in automated machinery, this dual-channel rotary joint provides a seamless, maintenance-friendly solution

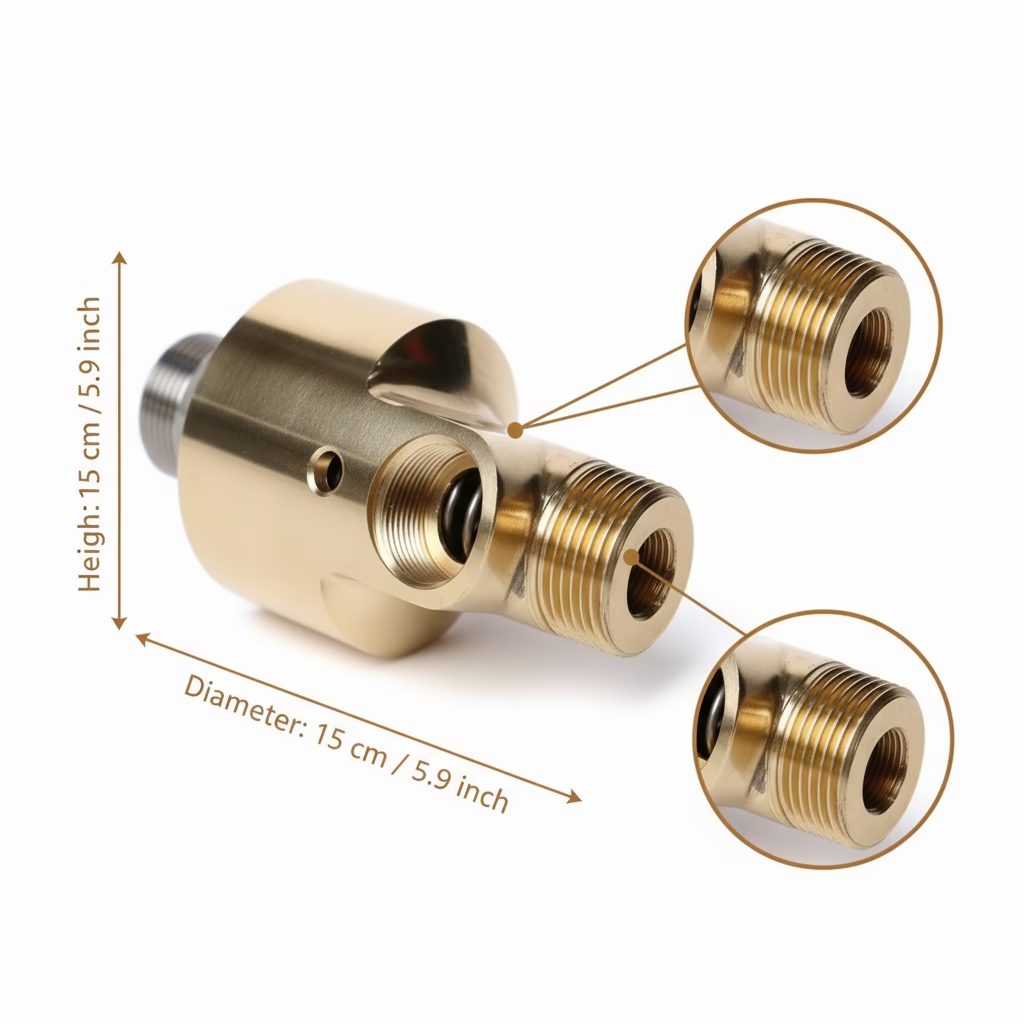

| Parameter | Specification |

|---|---|

| Number of Passages | 2 (Dual Passage) |

| Connection Type | 1/4"-18 NPT, BSPP, or SAE-ORB |

| Material | Stainless Steel, Carbon Graphite |

| Max Pressure | Up to 7,500 PSI (515 BAR) |

| Max Speed | Up to 500 RPM |

| Through Bore | 0.375" to 0.75" (varies by model) |

| Length | Approx. 4.7" (varies by model) |

| Diameter | Approx. 3.7" (varies by model) |

| Min. Torque to Rotate | 5.7 ft-lbs (7.73 Nm) |

Key Features

Key Features

Dual Independent Channels

Two separate flow paths let you deliver ink and a secondary medium (such as water for cooling or air pressure) at once, reducing plumbing complexity and space requirements.

Precision Sealing (Zero Leakage)

Balanced, spring-loaded PTFE composite seals ensure virtually leak-proof operation. These high-quality seals prevent mixing of media and dramatically reduce maintenance, even under high pressure.

High-Speed Capability

Engineered for modern presses, it supports rotation speeds up to ~3500 RPM. High-performance bearings and optimized clearances enable smooth operation at high RPM, ensuring consistent ink transfer on fast-running machines.

High Pressure & Temperature Tolerance

Rated for heavy-duty use, it handles pressures up to approximately 250 bar (3,625 psi) and temperatures up to ~250 °F (121 °C). This wide operating range makes it suitable for hot or solvent-based inks and harsh press environments.

Robust Construction

The housing and internal components are made of premium 316L stainless steel (optionally brass or carbon steel), providing excellent resistance to corrosion from inks and cleaning agents. This durability extends service life in the harsh chemical environment of printing presses.

Compact, Modular Design

The H Series’ self-contained design minimizes size and weight. It can be configured with standard NPT or BSP threaded ports and flange mounts to fit various press models. Modular cartridge seals allow easy replacement without dismantling the entire union.

Low Maintenance

Features such as external lubrication fittings and optional seal-wear indicator plugs simplify routine service. High-quality materials and seals maximize service intervals, helping printers achieve higher uptime and lower total cost of ownership.

Applications of Dual Passage Rotary Union

Rotary unions are integral to printing machines, seamlessly conveying fluids such as inks, cooling water, and air between fixed supply lines and rotating cylinders. The H Series Dual Passage union is ideal for applications like:

Offset and Flexographic Presses

Delivers ink to each color deck while concurrently supplying water (for dampening) or chilling fluid to inking rollers. This ensures uniform ink viscosity and temperature control throughout long runs.

Label and Packaging Printing

Supports high-speed rotary labelers and carton printers by feeding multiple inks (or inks plus cleaning solvent) simultaneously. Its high-pressure rating and dual channels help achieve precise registration and quick color changes with minimal downtime.

Web-Fed and Magazine Printing

Integrates into large web-offset presses to circulate fountain solution and coolant to large-diameter chill rollers. The robust design handles the heavy cyclic loads and rapid acceleration of modern newspaper and magazine lines.

Ink Coaters and Specialty Presses

Used in coating machines and industrial inkjet systems where separate delivery of ink and compressed air (for atomization or drying) is required. The dual-flow union simplifies system design by combining these flows in one compact unit.

Custom Printing Equipment

Any printing or converting machinery that needs simultaneous transfer of two media (e.g., ink plus pneumatic controls or ink plus water) will benefit. The H Series union can be tailored (materials, port types, passage sizes) to fit the exact media and mounting needs of custom presses.

Why Choose the H Type Dual Passage Rotary Union?

The H Series dual rotary union combines proven reliability with advanced engineering. Its superior sealing technology and rugged materials yield consistent, high-quality ink transfer, even under the extreme speeds and pressures of modern printing. By handling two media simultaneously, it streamlines machine design and cuts maintenance needs. In practice, this translates to higher productivity, better print accuracy, and reduced operational costs. When long print runs demand zero tolerance for ink starvation or fluid leaks, the H Series Dual Passage Rotary Union delivers the performance and peace of mind that printing press OEMs and production engineers require.

1. Superior Sealing and Leak Prevention

The rotary union employs advanced sealing materials such as carbon graphite and silicon carbide, ensuring minimal leakage even under high pressure and temperature variations. This reduces downtime and maintenance costs, enhancing operational efficiency.

2. Dual Independent Flow Passages

Unlike single-passage rotary unions, the H Type design supports two completely independent flow channels. This allows for the simultaneous transfer of different media types—such as hydraulic oil and coolant—through one compact unit, optimizing space and simplifying piping layouts.

3. Robust Construction for Harsh Environments

Constructed from high-grade carbon steel or stainless steel, this rotary union withstands corrosion, abrasion, and mechanical stress. The black oxide finish on carbon steel models adds an extra layer of protection against wear and oxidation.

4. Flexible Installation and Integration

With multiple thread standards and shaft sizes, the H Type Dual Passage Rotary Union can be easily integrated into existing systems. Optional O-ring face seal glands facilitate flush mounting, improving sealing integrity and simplifying assembly.

5. High-Speed and High-Pressure Performance

Engineered to handle rotational speeds up to 500 RPM and pressures up to 300 bar, this rotary union meets the demands of modern industrial machinery, ensuring smooth and reliable fluid transfer without compromising performance.

FAQ

Q1: What is the advantage of a dual-passage rotary union over a single-channel union?

A: A dual-passage (dual-flow) union carries two separate fluids or gases at once, saving space and simplifying design. Instead of installing two unions for ink and coolant (or ink and air), one H Series dual union handles both. This reduces potential leak points and maintenance. Overall, dual-flow unions boost system efficiency by integrating multiple media in one compact device.

Q2: What types of media can each channel carry?

A: Each channel operates independently, allowing you to use one for printing ink (either water-based or solvent-based) and the other for a different medium. Common combinations include ink plus water (for roll cooling), ink plus compressed air (for pneumatic controls), or ink plus cleaning solvent. The union’s seals are compatible with a wide range of fluids and gases. Always confirm chemical compatibility with the manufacturer, especially for aggressive solvent inks.

Q3: What are the operating limits (pressure, temperature, speed)?

A: Engineers designed the H Series dual rotary union for heavy-duty use. It typically handles pressures up to ~250 bar (3,625 psi) and temperatures up to ~250°F (121°C). Max rotational speed is around 3,500 RPM, depending on fluid type and port size. These ratings make it suitable for most high-speed printing applications. Refer to the specification table above for exact values and consult factory data for customized versions.

Q4: How is the H Series rotary union maintained?

A: Maintenance is straightforward. Routine checks for external leaks or unusual vibration are recommended. The union’s seals may need periodic replacement depending on usage. Most users report needing only occasional seal changes and lubrication due to its durable construction. External grease fittings and optional seal wear indicators simplify servicing, minimizing press downtime.

Q5: Can this rotary union be customized to specific needs?

A: Yes. The H Series design is modular. You can choose different housing materials (e.g., brass, carbon steel), port sizes, or threaded connections (NPT, BSP, etc.) to match your press hardware. Custom versions can also adjust pressure or temperature ratings for special applications. Work with the supplier to select the right options for your ink type, operating pressure, and mechanical mounting.

Conclusion

Our Dual Passage Rotary Union offers a reliable, efficient, and customizable solution for dual media transfer in rotating machinery. Designed with advanced sealing technology and robust materials, it meets the highest industrial standards for performance and durability. Optimize your pneumatic and hydraulic systems with this compact, leak-proof rotary union engineered for continuous operation and minimal maintenance.

Order with Confidence

Enjoy fast shipping, quality assurance, and dedicated customer support. Upgrade your rotating system today with our Dual Passage Rotary Union – engineered for performance, built to last.