Dual Pneumatic Rotary Union-Precision Air Transfer with Dual Passages

Original price was: $100.00.$90.00Current price is: $90.00.

- Max Pressure: 250 PSI (17 Bar)

- Max Speed: 500 RPM

- Port Size: 1/4″ NPT (BSPP Optional)

- Body Material: Hardcoat Anodized Aluminum

- Rotary Seal: Carbon Graphite

- Operating Temp: -20°F to 250°F (-29°C to 121°C)

- Weight: 0.65 lbs (295g)

Description

Dual Pneumatic Rotary Union Product Overview

The Dual Pneumatic Rotary Union is a precision-engineered solution designed to transfer two independent air or gas flows simultaneously while maintaining smooth 360-degree rotation. This dual passage rotary union ensures leak-free, high-speed, and high-pressure air transfer, making it essential for modern pneumatic systems, robotic arms, automated machinery, and industrial processing equipment.

We construct our Dual Pneumatic Rotary Union from high-quality materials, ensuring exceptional durability and long-lasting performance. Manufactured with high-quality materials such as stainless steel and anodized aluminum, this rotary union offers excellent corrosion resistance, long service life, and superior sealing performance. The precision-machined components and advanced sealing technology guarantee leak-free operation, even under high-pressure and high-speed conditions. With a wide range of temperature and pressure ratings, this rotary union is suitable for a variety of fluids, including air, water, oil, and chemicals.

| Parameter | Value/Options |

|---|---|

| Number of Channels | 2 (Dual Passage) |

| Media Compatibility | Air, inert gas, hydraulic fluid |

| Pressure Rating | Up to 50MPa (varies by model) |

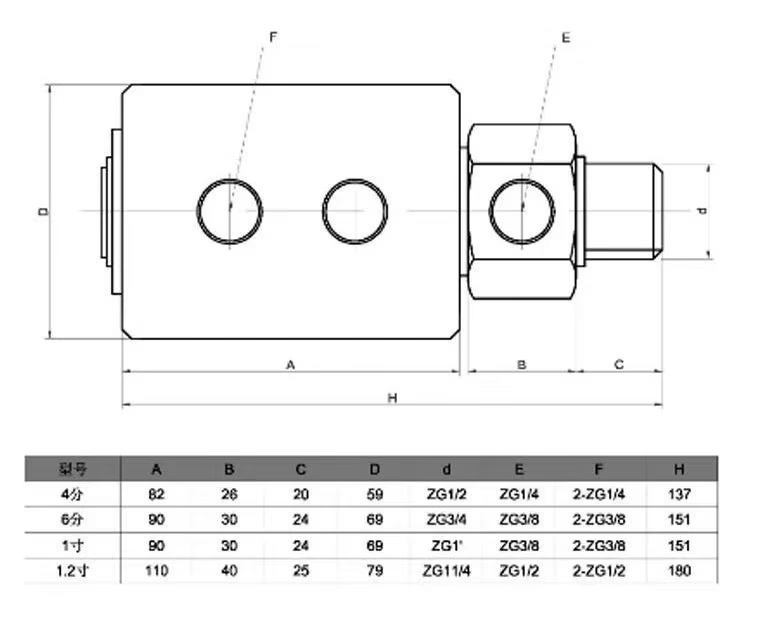

| Interface Size | G1/8", G1/4", G3/8", G1/2", G5/8" |

| Material | Stainless steel, carbon graphite, ceramic seals |

| Rotation Speed | Suitable for high-speed and low-speed operation |

| Customization | Available (contact for details) |

Key Features of Dual Pneumatic Rotary Union

Dual-Passage Design

Enables independent, simultaneous transfer of two different air or gas streams, preventing cross-contamination with dedicated sealing for each channel.

High-Quality Sealing Technology

Features balanced mechanical seals and compounded O-rings for long service life, minimal maintenance, and superior leak resistance-even at high speeds and pressures.

Heavy-Duty Construction

Manufactured from corrosion-resistant stainless steel and high-grade materials, ensuring durability in harsh industrial environments and continuous operation.

Versatile Applications

Ideal for pneumatic clutches, brakes, machine tool spindles, printing machinery, packaging equipment, and more, wherever dual media transfer is essential.

Customizable Interface

Available in multiple channel sizes (G1/8″, G1/4″, G3/8″, G1/2″, G5/8″) and pressure ratings up to 50MPa. Custom solutions are available to match your specific requirements.

Why Choose Us?

Quality Assurance

We commit to providing our customers with the highest quality products and services. All of our products undergo rigorous testing to ensure compliance with international standards and regulations.

Expertise and Experience

With years of experience in the industry, our team of experts possesses the knowledge and skills to deliver tailored solutions that meet your specific needs.

Customer Support

We offer comprehensive customer support, including technical assistance, installation guidance, and after-sales service. Our dedicated team of professionals is always ready to help you with any questions or concerns you may have.

Competitive Pricing

We offer competitive pricing without compromising on quality. Our goal is to provide you with the best value for your money.

Application

Dual passage rotary unions play a crucial role in the printing machinery sector, enabling efficient and simultaneous transfer of multiple fluids. Here are the typical applications of dual passage rotary unions in printing machinery:

Ink Supply Systems

Dual passage rotary unions are essential for managing the flow of inks in printing presses. They allow for the simultaneous transfer of different ink types or colors, ensuring that the printing process remains uninterrupted and that colors can be mixed or switched without downtime.

Coolant Circulation

In high-speed printing operations, maintaining optimal temperatures is vital. Dual passage rotary unions facilitate the concurrent flow of coolant alongside ink, helping to regulate the temperature of the printing heads and prevent overheating, which can lead to print quality issues.

Cleaning Systems

Printing machinery often requires regular cleaning to maintain performance and quality. Dual passage rotary unions can manage the flow of cleaning fluids while simultaneously handling inks or other operational fluids, streamlining maintenance processes without interrupting production.

Pneumatic Control

In many printing applications, pneumatic systems are used to control various functions such as paper feeding and alignment. Dual passage rotary unions enable the simultaneous transfer of air and other fluids (like lubricants), optimizing the operation of these pneumatic systems.

Lubrication Systems

Proper lubrication is critical for the smooth operation of moving parts in printing machines. Dual passage rotary unions can deliver lubricant while also managing other fluids necessary for operation, ensuring that all components function efficiently without cross-contamination.

Temperature Control

In addition to cooling systems, dual passage rotary unions can be used to manage heated fluids that maintain optimal operating temperatures for certain inks or substrates, enhancing print quality and consistency.

Multi-Color Printing

For machines that require multiple colors to be printed simultaneously, dual passage rotary unions allow for the efficient transfer of different colored inks, facilitating faster production times and reducing waste.

Integration with Automated Systems

As printing technology advances towards automation, dual passage rotary unions are integrated into automated systems where multiple media need to be transferred seamlessly, enhancing overall productivity.

Environmental Control

In some printing processes, it is necessary to manage vapors or other byproducts. Dual passage rotary unions can help in simultaneously transferring air or vacuum while managing other operational fluids, contributing to a cleaner working environment.

Custom Applications

Many modern printing setups require customized solutions tailored to specific operational needs. Dual passage rotary unions can be designed to meet unique requirements, ensuring compatibility with various fluids and operational parameters.

FAQ

Q: What is a dual pneumatic rotary union?

A: It’s a device that allows two separate air or gas streams to pass between stationary and rotating parts, using independent passages and seals for each stream.

Q: How do I select the right rotary union?

A: Consider your application’s pressure, speed, media type, number of channels, and connection size. Contact us for expert guidance or custom solutions.

Q: Can you provide custom rotary unions?

A: Yes! We offer tailored designs to meet your specific fluid transfer needs, including cross-referencing for existing equipment.

Order Your Dual Pneumatic Rotary Union Today!

Upgrade your industrial equipment with our high-performance Dual Pneumatic Rotary Union. Contact us today to learn more about our products and services, or to place an order. We look forward to serving you!