High Efficiency Pneumatic Dublin 1690 000 105 Rotary Union

Original price was: $350.00.$320.00Current price is: $320.00.

- Max Pressure (Air): 150 PSI

- Max Pressure (Hydraulic Oil): 3000 PSI

- Max Flow Rate (Air): Up to 40 CFM (1132 L/min)

- Max Speed: Up to 3000 RPM

- Rotor Connection: 1″-11 G RH

- Housing Connection: 1/4″-18 NPT

- Operating Temperature: Up to 250°F (121°C)

Description

Dublin 1690-000-105 Air Rotary Union Product Details

If you are searching for a reliable, high-performance rotary union but want to reduce your costs without compromising on quality, our alternative rotary union to the Dublin 1690 000 105 is the perfect choice. Engineered to meet and exceed industry standards, this rotary union offers the same robust functionality and durability as the original Deublin model, but at a significantly lower price.

This product is designed for pneumatic and air rotary applications, featuring a dual-channel design, balanced mechanical seals, and a self-supported construction, making it ideal for low-speed air clutches, brakes, and other industrial pneumatic systems. Our alternative rotary union is the smart choice for businesses looking to optimize their operational costs while maintaining excellent performance.

The Dublin 1690 000 105 rotary union is well-known for its durability and precision in air applications. However, the high cost of original branded rotary unions can be a barrier for many companies. Our alternative rotary union offers a cost-effective solution without sacrificing reliability, helping you reduce downtime and maintenance expenses.

Key Features of Dublin 1690 000 105 Rotary Union

Dual 1/4″ Channel Design

The 1690 series rotary union incorporates two independent 1/4-inch channels, allowing simultaneous air flow through separate passages without cross-contamination, enhancing system reliability and performance.

Balanced Mechanical Seals

Equipped with advanced balanced seals made from carbon graphite and tool steel, these seals minimize wear and friction, ensuring smooth operation and longer service life even under continuous use.

Self-Supported Construction

The rotary union is self-supported, eliminating the need for external bearing support, simplifying installation, and reducing overall system complexity.

Compact and Durable

Designed with a compact footprint and forged brass housing, the union withstands harsh industrial conditions while maintaining high precision and reliability.

Low-Speed Air Applications

Optimized for low-speed pneumatic applications such as air clutches, brakes, and other air-driven machinery components, supporting speeds up to 1000 RPM with stable performance.

Lubrication Port

Features an oil port for re-lubrication to maintain optimal seal and bearing performance, reducing maintenance intervals and extending operational life.

Versatile Mounting

Suitable for various industrial setups with standard NPT or BSP thread options for easy integration into existing pneumatic systems.

Advantages Over the Dublin 1690 000 105 Rotary Union

| Feature | Dublin 1690 000 105 | Our Alternative Rotary Union |

|---|---|---|

| Price | Premium, higher cost | More affordable, cost-effective |

| Seal Material | Carbon graphite & tool steel | Equivalent high-quality materials |

| Construction | Self-supported forged brass | Same durable forged brass housing |

| Speed Range | Up to 1000 RPM | Up to 1000 RPM |

| Maintenance | Requires periodic lubrication | Same lubrication port included |

| Warranty & Support | Manufacturer warranty | Competitive warranty and customer support |

| Customization Options | Limited to Deublin’s catalog | Flexible options available |

About Our Company

We specialize in manufacturing high-quality rotary unions tailored for industrial pneumatic and air applications. Our products are engineered with precision and tested rigorously to ensure they meet the demanding requirements of modern manufacturing and automation industries. With a focus on cost-effective solutions, we help businesses improve efficiency while reducing expenses.

Why Choose Our Alternative Dublin 1690 000 105 Rotary Union?

Cost Savings

Our rotary union offers a significant price advantage over the Dublin 1690 000 105, helping you reduce capital expenditure.

High Quality

Manufactured with premium materials and tested for durability, our product meets or exceeds industry standards.

Reliable Performance

Balanced seals and self-supported design ensure smooth operation and long service life.

Easy Installation

Compatible with standard thread sizes and designed for self-support, installation is quick and hassle-free.

Reduced Downtime

The lubrication port and durable construction minimize maintenance needs, keeping your operations running smoothly.

Customer Support

We provide responsive technical support and warranty coverage to ensure your satisfaction.

FAQs of Dublin 1690 000 105 Rotary Union

Q1: Can I use this union with MQL or dry air?

Yes. It is designed for both MQL and compressed air, as well as water-based coolants.

Q2: What’s the difference between 1690-000-105 and 1690-000-106?

The core design is similar, but the shaft connection dimensions may vary. Always check your OEM specs.

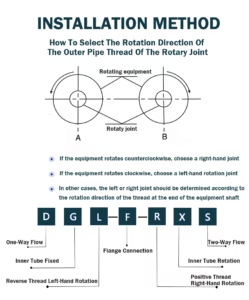

Q3: Is this suitable for reverse rotation?

Yes, the seal mechanism is bi-directional and safe for clockwise and counterclockwise rotation.

Q4: How do I verify compatibility with my spindle?

Send your machine model and coolant system specifications to our support team for a free consultation.

Installation and Maintenance Guidelines

Installation and Maintenance Guidelines

Alignment

Ensure precise alignment with the rotating shaft to avoid premature seal wear.

Lubrication

Regularly use the included oil port to lubricate bearings and seals, especially in continuous operation.

Thread Compatibility

Confirm NPT or BSP thread type before installation for leak-free connections.

Operating Speed

Do not exceed 1000 RPM to maintain seal integrity and prolong service life.

Periodic Inspection

Check for signs of wear or leakage and replace seals as necessary to avoid downtime.

Conclusion and Call to Action

If you are looking for a cost-effective, durable, and reliable alternative to the Dublin 1690 000 105 rotary union, our product is the ideal solution. It combines the essential features and performance of the original model with a more attractive price point, helping you optimize your budget without sacrificing quality.

Contact us today to learn more about our alternative rotary union, request a quote, or discuss customization options tailored to your specific industrial needs. Upgrade your pneumatic systems with confidence and save money with our trusted rotary union solutions.