Fluid Rotary Joint for Hydraulic and Pneumatic Applications

Original price was: $20.00.$15.00Current price is: $15.00.

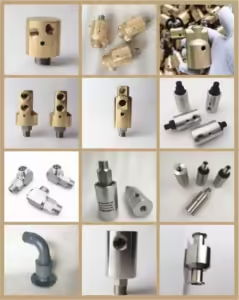

- Product Name: H Type Fluid Rotary Joint

- Media Supported:</strong> Steam, Water, Hot Oil, Air, Coolant

- Working Pressure: Up to 30 bar / 435 PSI

- Rotational Speed: Up to 3000 RPM

- Temperature Range: -20°C to 250°C

- Number of Passages: Single or Dual

- Body Material: Carbon Steel / Stainless Steel / Cast Iron

Description

The H Type Fluid Rotary Joint is a versatile and high-performance rotary union engineered for reliable fluid transmission between fixed and rotating equipment. Designed for industrial use, this joint offers a balanced seal structure and robust bearing system that supports high-pressure, high-speed, and high-temperature environments.

Whether transferring water, steam, thermal oil, or air, the H-type rotary joint ensures stable media flow with minimal leakage, making it an ideal solution for machinery in steel mills, textile plants, paper manufacturing, and plastic molding.

Manufactured with hardened alloys and precision machining, this fluid rotary joint offers long service life, reduced maintenance, and customizable interfaces to match specific operational needs.

| Parameter | Specification Example |

|---|---|

| Material | Brass, Stainless Steel |

| Shaft Material | Stainless Steel |

| Seal Type | Balanced mechanical seals |

| Bearing Type | Double ball bearings |

| Connection Types | Threaded (left/right), Flanged |

| Max Pressure | Up to 10 bar (varies by model) |

| Max Temperature | Up to 200°C (depending on seals) |

| Rotation | 360° continuous rotation |

| Fluid Compatibility | Water, Steam, Thermal Oil, Gas |

Key Features of the fluid rotary joint

Key Features of the fluid rotary joint

🔩 Robust Construction for Long-Term Reliability

Our fluid rotary joints are manufactured using high-grade stainless steel, brass, or aluminum alloy, offering superior resistance to corrosion, wear, and thermal expansion. The hardened rotor surface and precision-machined seals ensure minimal internal leakage even under high pressure.

🔧 Advanced Sealing Technology

Each unit incorporates carbon-graphite, mechanical, or elastomeric seals, specially designed to withstand the operating media and temperature range. These zero-leakage seals help avoid costly downtime and contamination.

⚙️ Smooth Rotational Performance

Equipped with high-precision bearings and a dynamically balanced rotor, the joint maintains low-friction torque and stable rotation, even at speeds up to 10,000 RPM. This results in reduced mechanical stress and enhanced operational efficiency.

🌡️ Wide Temperature and Pressure Range

From -30°C to 250°C and with pressure ratings of up to 300 bar, our fluid rotary joints can withstand extreme industrial environments. Optional cooling jackets are available for high-temperature applications.

🔄 Single, Dual & Multi-Passage Configurations

Choose from a variety of single-flow, dual-flow, or multi-passage rotary unions to suit your operational needs. Our multi-port designs support the simultaneous transfer of different media (e.g., hydraulic fluid and coolant) without cross-contamination.

🧩 Customizable Interface Options

We offer a full selection of threaded, flanged, and quick-connect adapters to match different shaft sizes, pipe fittings, or OEM equipment requirements.

🛠️ Low Maintenance & Easy Installation

Designed for minimal service requirements, most units are pre-lubricated for life and feature a modular design for fast installation and replacement.

Applications

Applications

Textile Industry

The H-type joint supplies hot water and steam to rotating dyeing machines and drying drums. It ensures even heating and prevents condensation buildup during fabric processing.

Paper Manufacturing

In drying cylinders and calender rolls, the joint allows for efficient thermal oil or steam flow. Its high sealing performance supports continuous operation under high load and temperature.

Plastic and Rubber Machinery

Molding systems use this rotary joint to control temperature via hot oil or water in rotating molds. It helps stabilize mold temperature and reduces cycle times.

Steel Rolling Mills

Rotating components, such as cooling drums or roll chocks, require consistent water flow. The joint’s pressure and heat resistance make it ideal for these harsh environments.

Food Processing

Steam and water rotary transmission is common in rotating ovens or cookers. The H-type rotary joint meets hygiene and temperature demands safely and efficiently.

Why Choose Our Rotary Joint Supplier?

Factory-Direct Source

We manufacture and supply directly, ensuring better control of quality and cost.

Customization Experts

We adapt materials, thread types, seal specs, and sizes to match your application.

Global Experience

Exported to over 60 countries for industries including paper, textile, plastics, and metallurgy.

Quick Turnaround

Most standard models ship within 7–10 working days.

Technical Support

Receive drawings, manuals, or support from our experienced engineering team.

FAQ

FAQ

Q1: What makes the H-type rotary joint different from standard models?

A1: The H type features a balanced seal structure and is built for higher temperatures and pressures, making it ideal for demanding thermal and fluid systems.

Q2: Can I use this rotary joint for steam and hot oil applications?

A2: Yes. It’s specifically designed to handle high-temperature media like steam and thermal oil with appropriate sealing materials.

Q3: Are multi-channel (dual-passage) versions available?

A3: Yes. We offer both single-passage and dual-passage designs to accommodate complex fluid control systems.

Q4: Can I customize thread type and connection interface?

A4: Absolutely. We support BSP, NPT, SAE, and flanged threads depending on your equipment requirements.

Q5: What’s the typical service life of the H-type rotary joint?

A5: With proper installation and routine maintenance, the joint can operate for 1–3 years under normal industrial use.