Description

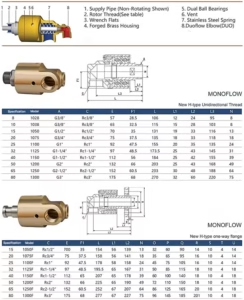

HD Mono Flow Rotating Joint: Product Overview

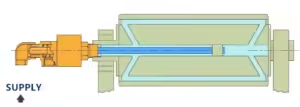

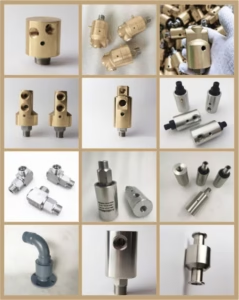

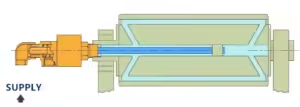

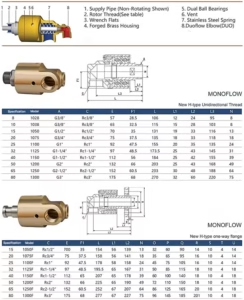

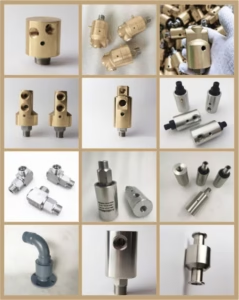

Introducing the HD Mono Flow Rotating Joint, a cutting-edge solution designed to meet the demanding needs of various industries. It is divided into one-way flow type HD type rotary joint and two-way flow type HS type rotary joint. It adopts plane sealing technology.This rotary joint is engineered for efficiency, reliability and versatility, making it an essential component in systems requiring fluid transfer while allowing for rotational movement.

Compact Design: It boasts a small size and lightweight construction, which facilitates easy installation and integration into existing systems.

Advanced Sealing Technology: Utilizing innovative plane sealing technology, this joint minimizes leakage and enhances operational efficiency, ensuring that your fluid transfer processes remain uninterrupted.

Low Friction Torque: Designed to reduce friction, the HD Mono Flow offers smooth operation even under high-speed conditions, contributing to lower energy consumption and extended service life.

Versatile Applications: Ideal for various media including water, oil, and hydraulic fluids, the HD Mono Flow is suitable for use in cooling systems, manufacturing processes, and other applications where rotational movement is required.

Our seals are on CNC machine tools and special grinding machines. The finished, mirror-like surface makes the seal more reliable and high-precision rolling bearings also used to make it rotate smoothly.

Our seals are on CNC machine tools and special grinding machines. The finished, mirror-like surface makes the seal more reliable and high-precision rolling bearings also used to make it rotate smoothly.

The Mono Flow Rotating Joint is perfect for:

The Mono Flow Rotating Joint is perfect for:

Cooling Systems: Efficiently transfers cooling fluids in machinery and equipment.

Manufacturing Processes: Ensures reliable fluid delivery in continuous production lines.

Hydraulic Systems: Provides seamless integration in hydraulic machinery for optimal performance.

What is the Mono Flow Rotating Joint?

What is the Mono Flow Rotating Joint?

The HD Mono Flow Rotating Joint is a rotary union designed for cooling applications. It allows for the efficient transfer of fluids such as water, hydraulic oil and coolant while enabling rotational movement. Its compact design and lightweight construction make it ideal for various industrial settings.

What industries commonly use the Mono Flow Rotating Joint?

Plastic Manufacturing: For cooling processes in calendering equipment.

Hydraulic Systems: To manage fluid transfer in hydraulic machinery.

Coating Machinery: Ensures efficient application of coatings by managing fluid flow.

What are the pressure and temperature ratings for the HD Mono Flow?

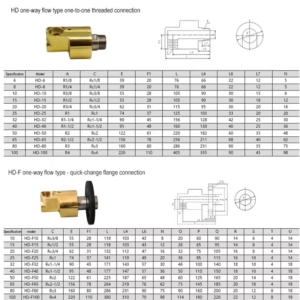

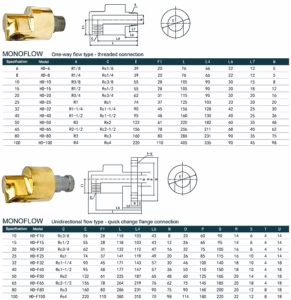

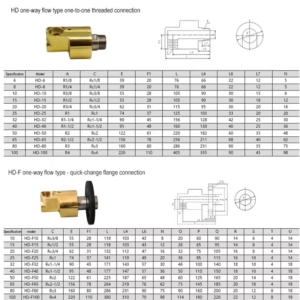

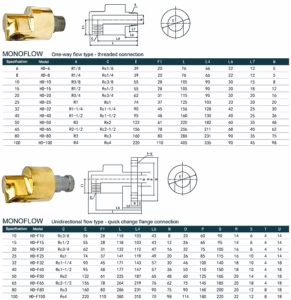

The HD Mono Flow Rotating Joint typically operates at a maximum pressure of up to 1.0 MPa (approximately 145 psi) and can handle temperatures ranging from 0°C to 250°C (32°F to 482°F), depending on the specific model and application.

How does the sealing mechanism work in the HD Mono Flow?

The sealing mechanism utilizes advanced plane sealing technology, which incorporates high-quality materials such as impregnated graphite and tungsten carbide to resist wear from impurities like rust and debris. This design ensures a reliable seal that minimizes leakage during operation.

What maintenance practices recommended for the HD Mono Flow?

Inspecting seals and bearings for wear.

Keeping the joint clean to prevent contamination.

Following manufacturer guidelines for specific maintenance schedules can extend the joint’s lifespan.

Can the HD Mono Flow customized for specific applications?

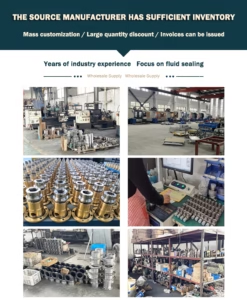

Yes, many manufacturers offer customization options for the HD Mono Flow Rotating Joint, allowing adjustments in size, material composition, seal types, and connection configurations to meet unique operational requirements.

What are some common applications for the HD Mono Flow Rotating Joint?

Cooling Systems: Managing cooling fluids in machinery and equipment.

Hydraulic Equipment: Facilitating fluid transfer in hydraulic systems.

Industrial Mixers: Ensuring continuous fluid flow during mixing processes.

How does the performance of the HD Mono Flow compare to other rotary joints?

The HD Mono Flow offers significant advantages such as lower friction torque, compact design, and advanced sealing technology compared to traditional rotary joints. These features contribute to enhanced efficiency, reduced maintenance needs, and improved operational reliability.

Where can I purchase an HD Mono Flow Rotating Joint?

The HD Mono Flow Rotating Joint can purchased through various industrial supply companies, specialized hydraulic equipment suppliers, or directly from manufacturers’ websites. It’s advisable to consult with sales representatives to ensure you select the right model for your specific application needs.

Our seals are on CNC machine tools and special grinding machines. The finished, mirror-like surface makes the seal more reliable and high-precision rolling bearings also used to make it rotate smoothly.

Our seals are on CNC machine tools and special grinding machines. The finished, mirror-like surface makes the seal more reliable and high-precision rolling bearings also used to make it rotate smoothly.

The Mono Flow Rotating Joint is perfect for:

The Mono Flow Rotating Joint is perfect for:

What is the Mono Flow Rotating Joint?

What is the Mono Flow Rotating Joint?