High Speed Pneumatic Rotary Union for Industrial Systems

Original price was: $35.00.$30.00Current price is: $30.00.

- Max Pressure: Up to 10 bar (145 psi)

- Max Temperature: Up to 80°C (176°F)

- Rotational Speed: Up to 3,000 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

Description

The High Speed Pneumatic Rotary Union is expertly engineered to deliver smooth, reliable, and leak-free air and fluid transfer in high-speed industrial applications. Utilizing cutting-edge seal and bearing technology ensures that pressurized air or gases maintain their integrity during transmission, even at high rotational speeds. This rotary union is essential for applications requiring precise air delivery, such as paint robots in automotive manufacturing, rotary tables in packaging, and wind turbine blade systems in renewable energy.

The union’s innovative design incorporates high-performance seals that resist wear and withstand exposure to varying pressures and temperatures, ensuring long-lasting operation. Its low torque profile reduces mechanical stress on machinery, enhancing overall equipment lifespan and reducing maintenance costs.

Available in both single and multiple passage models, it caters to simple and complex operational needs. The multiple passage rotary unions allow the simultaneous transfer of different gases or air streams, making them ideal for sophisticated industrial processes.

Constructed with premium materials, this rotary union offers excellent corrosion resistance and mechanical strength, suitable for harsh industrial environments.

How pneumatic rotary union work?

How pneumatic rotary union work?

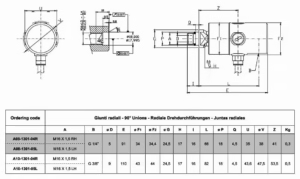

High Speed Pneumatic Rotary Union Technical Specifications

| Specification | Details |

|---|---|

| Max Air Pressure | 250 PSI |

| Max Hydraulic Pressure | 1,000 PSI |

| Max Vacuum Pressure | 28" Hg |

| Max Operating Temperature | 225°F (107°C) |

| Seal Material | Carbon Graphite-to-Carbide |

| Housing Material | Hastelloy, Super-Duplex Stainless Steel, Aluminum |

| Bearing Type | Stacked Radial Contact Ball Bearings |

| Thread Types | All Common Thread Types Available |

Key Features of Our High-Speed Pneumatic Rotary Union

Our high-performance rotary union is purpose-built for high-speed pneumatic applications. Explore the key features that set our product apart:

🚀 Ultra-High Rotational Speed – Up to 10,000 RPM

We engineer every union with precision-balanced components to withstand extreme rotational speeds. This makes it ideal for demanding applications like CNC spindles, rotary tables, and robotic tooling that operate at high RPMs.

💨 Non-Contacting Seal Technology

The union uses labyrinth or air-sealing systems that eliminate friction and wear. This zero-contact sealing minimizes heat generation and dramatically extends the service life, while preventing leaks during high-speed rotation.

🔩 Compact & Lightweight Structure

Our design focuses on reducing the overall footprint and weight. It’s perfect for systems where space is limited and load sensitivity is critical, such as in robotic end-effectors and automated packaging equipment.

⚙️ Durable, Corrosion-Resistant Materials

We manufacture the housing from anodized aluminum or stainless steel, ensuring excellent corrosion resistance and strength. The internal components are made to handle compressed air, inert gases, and vacuum environments safely.

🔄 Multi-Passage Air Transfer Capability

Choose from 1, 2, or 4 independent air channels, enabling you to control multiple pneumatic circuits through a single rotary joint. Each passage is completely sealed to prevent cross-contamination between air flows.

🧩 Flexible Port & Mounting Options

We offer standard NPT, BSPT, and metric threads, plus optional flange or face mounting styles. These configurations make it easy to integrate the union into both new machinery and retrofitted systems.

🌡️ Broad Operating Temperature Range

Our unions perform reliably in environments ranging from -10°C to +80°C, and optional seals (like FKM or PTFE) allow for higher or chemically aggressive conditions. This makes them suitable for laboratory automation, medical devices, and factory robotics.

🔧 Maintenance-Free Operation

Thanks to non-contacting seals and high-precision bearings, the union requires little to no maintenance. This reduces downtime, cuts costs, and supports long-term continuous use in 24/7 automation environments.

🔌 Vacuum & Compressed Air Compatibility

Whether your system requires positive air pressure or vacuum, our rotary union ensures smooth and uninterrupted flow. The inner flow path is optimized to reduce turbulence and pressure drops, even under high flow conditions.

🌍 OEM & Custom Engineering Support

We can match or replace existing Deublin or DSTI models with improved pricing and lead time. Additionally, we offer fully customized rotary air connectors to fit your unique system specifications or international project needs.

Applications of High Speed Pneumatic Rotary Union

Manufacturing Automation

Essential for pneumatic tools and robotic arms in assembly lines, providing a reliable supply of compressed air for enhanced productivity.

Textile Production

Used in textile machinery for efficient operation of pneumatic controls, ensuring smooth fabric handling and processing.

Food Processing

Supports equipment that requires pneumatic control systems for packaging and processing applications, ensuring food safety through reliable operation.

Automotive Industry

Ideal for use in assembly lines where high-speed pneumatic tools are employed to improve efficiency and precision.

Why Choose Our High Speed Pneumatic Rotary Union?

Choosing the right pneumatic rotary union is crucial for high-speed automation systems. Here’s why thousands of engineers, OEMs, and industrial buyers trust our solution:

🔩 Engineered for Ultra-High Speed Applications

We design our pneumatic rotary unions to operate smoothly at speeds up to 10,000 RPM. This makes them ideal for CNC spindles, robotic arms, and other high-speed rotating systems where traditional swivel joints fail.

💨 Zero-Leakage Air Transfer

Our unions feature advanced non-contacting seals that deliver consistent, leak-free performance. Whether you’re transferring compressed air or vacuum, you can expect maximum efficiency with minimal air loss—critical for precision automation.

🔄 OEM-Compatible Design

You can directly replace expensive brands like Deublin, DSTI, or Maier with our products—without needing to redesign your setup. We match mounting dimensions, port threads, and passage configurations, making our rotary unions the perfect OEM alternative.

⚙ Customization Options for Any Industry

We support custom features like:

1, 2, or 4 air channels

Metric/NPT/BSPT threads

Flange mounting

High-temperature or corrosion-resistant coatings

Whether for robotic welding, food packaging, or semiconductor automation, we tailor solutions to your specific needs.

💰 Competitive Factory Pricing

By manufacturing in-house, we eliminate excessive middleman costs. This enables us to offer premium-quality rotary air unions at competitive prices, particularly for OEM and bulk orders.

🚚 Fast Lead Time & Global Delivery

We keep popular models in stock and offer rapid customization turnaround. With reliable shipping via DHL, FedEx, and sea freight, we serve clients worldwide—from Europe to North America to Southeast Asia.

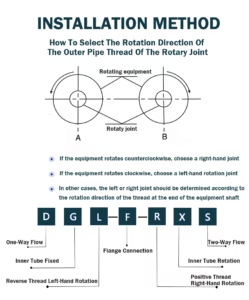

Instructions

1. Keep the drum and pipe wall clean, pay more attention to new equipment, and add filters when necessary to avoid abnormal wear of the rotary joint caused by foreign matter.

2. When the rotary joint is found to be leaking, stop the machine in time to check the cause of the leak, and do not work at high speed to avoid abnormal damage to some parts.

3. Do not run it idling for a long time when the medium is not flowing.

4. The structure inside the rotary joint will rust due to long-term disuse of the machine. Please note that if you clean the rust before using it, it will be stuck and dripping.

5. For those with oil-filled devices, please fill them with oil regularly to ensure the reliability of the bearing operation.

6. The rotary joint that circulates the hot medium should be heated gradually to avoid sudden temperature changes.

Maintenance instructions

1. When disassembling the rotary joint, pay attention to the impact of excessive temperature on the body. 2. When disassembling and opening the rotary joint, pay attention to the assembly sequence and keep the original state of the internal structural components to analyze the cause of the leak.

3. Check the wear condition and thickness change of the sealing surface (normal wear is 5-10mm); observe the friction track of the sealing surface to see if there are problems such as three-point intermittent contact or contact surface. This is an abnormal wear condition and should be repaired in time.

FAQ

Q1: Can this rotary union handle both air and hydraulic oil at the same time?

A1: Yes, our multi-passage rotary unions can handle different media independently without cross-contamination.

Q2: Is this rotary union suitable for vacuum applications?

A2: Absolutely. It is specifically designed to handle both vacuum and positive pressure systems efficiently.

Q3: Can I customize the connection size and thread type?

A3: Yes, we offer various thread types such as NPT, BSP, and custom options to fit your specific requirements

⭐ Customer Reviews

⭐ Customer Reviews

“We replaced our Deublin units with these and got equal performance at half the cost.”

— Manufacturing Engineer, Germany

“Lightweight, reliable, and easy to install. Runs smoothly at 9000+ RPM.”

— Automation OEM, Korea