H Series High Temperature Rotary Union for Fluid Systems

Original price was: $60.00.$52.00Current price is: $52.00.

- Max Pressure: Up to 15,000 PSI (1,000 bar)

- Max Temperature: Up to 300°C (572°F)

- Rotational Speed: Up to 3,500 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

Description

The H Series High Temperature Rotary Union is purpose-built to handle the demanding requirements of extreme heat applications. Engineered for precision and durability, this rotary union ensures smooth and leak-free transfer of steam, thermal oil, and other high-temperature fluids across rotating interfaces. With rugged construction, advanced sealing technology, and customizable options, the H Series is ideal for industries where thermal resistance and continuous rotation are critical.

Whether you’re operating in a die casting plant, rubber mill, or plastic extrusion line, the H Series provides the durability and performance you can count on—even at elevated temperatures.

Key Features

Wide Temperature Range

Handles temperatures up to 300°C (572°F), making it ideal for high-temperature applications in industries such as plastics, paper, textiles, and chemical processing.

Robust Pressure Rating

Supports pressures up to 28 bar (406 PSI), ensuring safe and efficient operation even under challenging conditions.

Versatile Media Compatibility

Suitable for steam, hot water, cooling water, heat transfer oil, and gas, providing flexibility for diverse industrial processes.

Maintenance-Free Design

Incorporates self-lubricating carbon plain bearings, eliminating the need for regular greasing and reducing overall maintenance costs.

Modular and Flexible

The modular system allows for customization to meet specific operational requirements, including adaptable connection configurations and optional nitrogen blanketing.

Advanced Sealing Technology

Features balanced sealing designs and high-precision ball bearings for zero leakage and extended service life.

High Reliability and Longevity

Engineered with high-quality materials such as stainless steel shafts and brass housings, ensuring long-term durability and resistance to wear.

Applications

The H Series High Temperature Rotary Union is engineered for diverse industrial environments requiring fluid transfer under high heat and continuous motion:

1. Plastics and Rubber Processing

Used in calendaring, extrusion, and injection molding machines to circulate thermal oil or steam for precise mold temperature control.

2. Steel and Metal Manufacturing

Handles high-temp water or oil in roll heating systems and continuous casting equipment where durability is essential.

3. Paper and Textile Industries

Transfers steam to dryer cans or thermal oil to textile rollers, maintaining consistent temperature and ensuring product quality.

4. Chemical and Petrochemical Plants

Facilitates the safe transfer of heated media in reactors and mixers, ensuring thermal stability and chemical resistance.

5. Food and Beverage Processing

Ideal for steam sterilization or jacketed heating systems where high-temperature sanitation is required.

Why Choose Our High Temperature Rotary Union?

Our High Temperature Rotary Union stands out due to its innovative design and exceptional performance capabilities. With a commitment to quality and reliability, this product not only meets but exceeds industry standards, providing a dependable solution for your high-temperature fluid transfer.

1. Superior Performance in Extreme Conditions

The H Series is engineered for high reliability in extreme temperatures and pressures, ensuring uninterrupted operation and minimizing downtime in critical industrial processes.

2. Low Maintenance and Cost Efficiency

With its self-lubricating bearings and minimal moving parts, the H Series reduces the frequency and cost of maintenance, providing long-term savings for your facility.

3. Flexible and Customizable

The modular construction allows for easy adaptation to specific requirements, including different connection types, flange positions, and optional features such as nitrogen blanketing for enhanced oil protection.

4. Safety and Compliance

Available with ATEX certification for use in potentially explosive environments, the H Series meets stringent international safety standards.

5. Global Support and Service

Supported by a worldwide network of authorized service centers and 24-hour spare parts supply, ensuring rapid response and minimal downtime.

FAQ

Q1: What media can the H Series High Temperature Rotary Union handle?

A: It is suitable for steam, hot water, cooling water, heat transfer oil, and various gases.

Q2: Is the rotary union maintenance-free?

A: Yes, the self-lubricating bearings and robust construction make it virtually maintenance-free during normal operation.

Q3: Can the rotary union be customized for specific applications?

A: Absolutely. The modular design allows for customization of connection types, sealing mechanisms, and optional features to meet unique operational requirements.

Q4: Does the product comply with international safety standards?

A: Yes, it is available with ATEX certification and manufactured according to recognized international standards.

Q5: How can I get support or spare parts?

A: With a global network of dealers and 24-hour spare parts supply, support is always close at hand.

How to Order

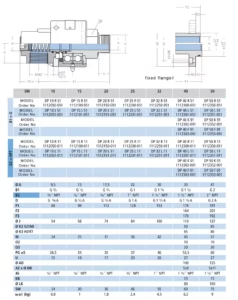

To select the right H Series High Temperature Rotary Union for your application, please provide:

- Media type (steam, water, oil, gas)

- Operating temperature and pressure

- Required connection type and size

- Any specific customization needs (e.g., ATEX certification)

Optimize your industrial process with the H Series High Temperature Rotary Union—engineered for performance, reliability, and peace of mind.