Dual Flow Rotary Union – HS Series for Efficient Fluid Transfer

Original price was: $20.00.$15.00Current price is: $15.00.

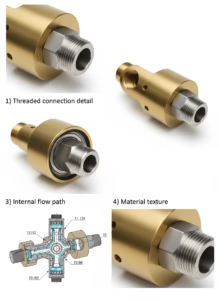

- Product name: HS-G rotary joints

- Material: Stainless Steel Brass

- Pipe Clamp Size: 15/20/32/40/50/65/80

- Max.Speed: 1000RPM

- Max. Pressure: 1.6MPa

- Max.Temperature: 100℃

- Applicable Medium: Water, oxygen, air, oil

Description

HS Dual Flow Rotating Joint: Product Overview

The HS Double Flow Dual Flow Rotating Joint is engineered for applications requiring the simultaneous transfer of two different media—such as steam and condensate, water and oil, or air and coolant—through a single rotating interface. With its robust construction, precision sealing, and long service life, this dual-flow rotary joint provides a reliable solution for continuous fluid transfer in demanding industrial environments.

Built to meet the high standards of modern manufacturing, the HS series ensures leak-free performance, low torque operation, and high rotational stability, making it ideal for machinery that operates under high temperature, high pressure, or continuous rotation.

Working Principle

The HS Double Flow Rotating Joint allows two separate media to enter and exit through independent channels while the machine is rotating.

One passage can be used for supply (inlet), and the other for return (outlet)—enabling efficient heat transfer or fluid circulation.

This dual-channel design eliminates the need for multiple rotary joints, reducing both installation space and maintenance complexity. Internal sealing components maintain perfect separation between the two passages, ensuring zero media mixing and high operational safety.

Key Features

Dual Flow Design:

Handles two independent flow paths for separate fluid or gas transfer, preventing cross-contamination between media.

Advanced Sealing Technology:

Utilizes mechanical seals made of carbon graphite and silicon carbide for exceptional wear resistance and thermal stability.

High Temperature & Pressure Capability:

Designed to withstand temperatures up to 180°C and pressures up to 20 bar, ensuring performance stability under harsh conditions.

Precision Bearings:

Incorporates double-row ball bearings for excellent support and smooth rotation, reducing vibration and extending service life.

Compact & Modular Construction:

Simplifies installation and maintenance, with options for both fixed and rotating syphon systems.

Versatile Connection Options:

Available in threaded, flanged, and custom connection types, suitable for integration with diverse machinery and piping systems.

Applications

The HS Double Flow Dual Flow Rotating Joint is widely used across various industries, including:

-

Paper & Printing Machines: For steam and condensate flow during drying and heating processes.

-

Plastic & Rubber Industry: For hot oil and water circulation in heating rollers and molds.

-

Textile Machines: For cooling or heating cylinders with dual medium systems.

-

Chemical Processing Equipment: For transferring fluids under mixed temperature and pressure environments.

-

Steel & Metal Processing: For coolant and lubricant circulation in rotating rolls or spindles.

-

Energy Systems: In turbines, generators, and rotary reactors for dual-medium circulation.

Why Choose Our HS Series?

Our HS Double Flow Dual Flow Rotating Joint combines German-inspired precision engineering with cost-effective performance.

Compared to leading brands such as Deublin or Maier, our HS series offers equivalent quality at a significantly more competitive price—without compromising performance or reliability.

Each rotary joint undergoes strict leak testing, balance calibration, and endurance trials before shipment, ensuring consistent operation from the first installation.

Conclusion

The HS Double Flow Dual Flow Rotating Joint offers an intelligent solution for engineers seeking to optimize fluid transfer performance, machine reliability, and system compactness. With its advanced dual-channel design, precision manufacturing, and flexible configuration, it stands out as a trusted choice across multiple industries.

Upgrade your system with the HS series and experience superior sealing performance, extended service life, and unmatched value in your rotating applications.