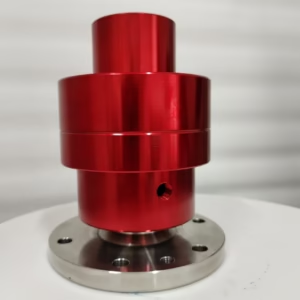

Hydraulic Rotary Joint for Sealed Fluid Transfer Solutions

Original price was: $35.00.$31.00Current price is: $31.00.

-

- <

li style=”list-style-t

-

- yp

e: non

- e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

- e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li style=”list-style-t

- tyle=”list-style-type: none;”>

- yp

e: non

e;”>

-

- <

li><strong>Size Range:</strong></p>

- <ul></

<p>strong

- > 1/8″

- (DN06) to 1 1/2″ (DN40)

- Maximum Pressure:</strong> Up to 400 bar

- Maximum Temperature: Up to 120°C

- Speed Capability: High-speed options available

- <stro

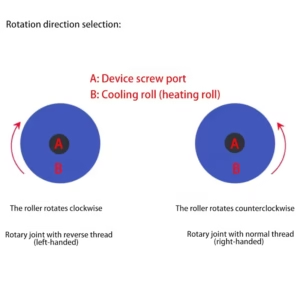

- ng>Thread Types:

LH & RH UNF, Metric, BSP & NPT

Description

A hydraulic rotary joint (rotary union) provides a sealed connection between stationary hydraulic piping and a rotating machine component. This swivel joint enables continuous transfer of hydraulic oil and other fluids under high pressure into rotating equipment, without leakage or torsion on the lines. By maintaining robust seals, the hydraulic rotary joint allows rotating drums, spindles, or tables to receive hydraulic power or coolant while spinning. These devices (also called rotary unions or swivel joints for hydraulic oil) are used in demanding applications – from CNC machine tools and automated packaging lines to wind turbine pitch systems – wherever reliable, leak-free rotation is required.

Key Features

High-Pressure Performance

Engineered for hydraulic service, these hydraulic rotary joints are designed to withstand very high pressures (commonly up to 250–350 bar and beyond in specialized units). Precision mechanical seals (balanced face seals or lip seals) maintain leak-free operation even under extreme pressure.

Wear-Resistant Materials

Critical components (housings, shafts) are made of stainless steel, alloy steel, or aluminum, providing excellent corrosion and abrasion resistance. Robust bearings and hard-wearing seal materials ensure long life in harsh conditions.

Multi-Passage Capability

Available with multiple fluid passages (from single-circuit up to 24 channels), our rotary unions can simultaneously transfer multiple media (e.g., separate hydraulic circuits or oil+coolant) through a single compact unit. Engineers individually seal each channel to prevent cross-contamination.

360° Continuous Rotation

The swivel design permits unlimited rotation without twisting hoses, supporting continuous 360° motion. Advanced bearing arrangements and precision machining keep friction low, reducing wear and heat build-up.

High-Speed Compatibility

Specialized versions with gap seals or dynamic sealing can operate at high RPM. Gap-seal rotary joints, for example, allow smooth rotation at speeds up to ~1000 RPM or more without excessive friction. Low-torque designs minimize inertia on the drive.

Durable, Low-Maintenance Design

Leading manufacturers emphasize long service life and minimal maintenance. Manufacturers conduct rigorous testing on each unit and can integrate predictive-maintenance sensors to monitor performance. Overall, engineers design these rotary unions to operate reliably year after year under heavy-duty cycles.

Versatile Media Handling

In addition to hydraulic oil, they support various fluids – water, coolants, air/gas, and other process media. Models are offered for a wide temperature range (typically –40°C to +200°C, with special designs up to +390°C) and for aggressive or non-Newtonian fluids as needed.

Applications

Hydraulic rotary joints are used across many industries where fluids must transfer to moving parts. Common applications include:

CNC Machine Tools & Automation

Deliver hydraulic power or coolant to rotating spindles, rotary tables, and machining centers. Multi-passage joints feed multiple tool heads or circuits in milling and turning machines for precise, uninterrupted operation.

Construction & Mining Equipment

Supply hydraulic fluid to rotating booms, turrets, and attachments (cranes, excavators, rock drills) where unrestricted motion and heavy-duty sealing are essential.

Wind Turbines (Pitch/Yaw Systems)

Transfer hydraulic oil from the stationary nacelle to the turning hub and blade-pitch cylinders. High-quality swivel joints ensure reliable pitch actuation under variable wind loads, minimizing oil leakage.

Injection Molding & Plastics

Provide cooling water or hydraulic fluid to rotary mold tables and turbines in injection and blow molding machines. Swivel unions allow continuous mold rotation while circulating heat-transfer fluid.

Packaging & Printing Machinery

Enable continuous flow of oils, inks, and coolants in high-speed rotary packaging lines and printing presses. Uninterrupted fluid supply prevents thermal deformation and maintains product quality.

Marine & Offshore Equipment

Used in shipboard loading arms, swivel hoses, and drilling rigs to transfer oil, fuel, or water between fixed infrastructure and rotating joints. Multi-channel unions streamline complex fluid routing on marine vessels.

Renewable Energy & Utilities

Feed hydraulic or water circuits in solar trackers, turbine yaw systems, and steam-generators. Rotary joints enhance efficiency and uptime in renewable energy applications.

Why Choose Us

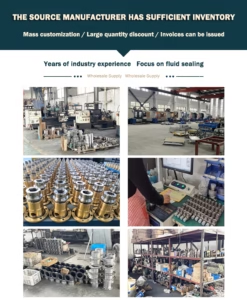

Proven Expertise

Backed by decades of experience and in-house R&D, we design and produce hydraulic rotary joints with precision engineering. Our team understands the challenges of rotary fluid transfer in North American and European markets.

Certified Quality & Materials

We maintain strict quality control and comply with international standards (PED 2014/68/EU, AD2000-HPO, EN ISO 3834, etc.). All critical parts come from audited suppliers, and each unit is fully tested before shipment. This yields reliable performance and longer uptime.

Customized Solutions

With numerous patents and a full prototyping capability, we tailor joint designs to your needs – special media, extreme pressures or temperatures, multi-circuit configurations, etc. Every rotary joint is engineered to match the precise application requirements.

Global & Local Support

We offer worldwide logistics and on-site service. Our distribution network spans North America and Europe, including authorized service centers (USA, Italy, etc.) and 24/7 spare-parts supply. Local teams are available to assist with installation, start-up, and maintenance anywhere in NA/EU.

Comprehensive Service

From initial inquiry through the product life cycle, we provide technical guidance, digital documentation, and maintenance support. Advanced options like integrated sensors for condition monitoring (Industry 4.0) and ATEX-certified versions are available to meet stringent industrial requirements.

FAQ

Q: How do I select the right hydraulic rotary joint?

A: Identify your maximum operating pressure, rotational speed, media type, number of required passages, and mounting interface. Choose a unit whose rated pressure and RPM exceed your needs. Always verify compatibility with the hydraulic fluid and temperature range. For best results, consult the factory or an engineering specialist – proper selection avoids overloading the joint’s design limits.

Q: What fluids, pressures, and temperatures can this joint handle?

A: Our rotary unions handle standard hydraulic oils, water-based coolants, glycols, etc. Pressures up to ~350 bar (5,000 psi) are typical, and special high-pressure versions exceed 400 bar. The temperature range is roughly –40°C to +200°C in common models, with high-temp designs available to ~+390°C for hot oil. (Check fluid compatibility and viscosity for your application.)

Q: What maintenance is required?

A: These joints require minimal upkeep. We recommend a periodic inspection schedule – check for seal wear, bearing condition, and lubrication of any lubrication fittings. Replace seals at regular intervals or when wear is evident. Proper installation and alignment are critical; following the manufacturer’s instructions will maximize life. In practice, failures are usually preventable with correct assembly and scheduled maintenance.

Q: Can you provide custom or multi-passage configurations?

A: Yes – our engineers specialize in custom rotary unions. We can incorporate multiple passages (up to 24 or more), special flange connections, exotic materials or seals, and complete turnkey assemblies. Every joint is built to your spec, whether it’s a simple single-channel swivel or a complex multi-circuit manifold.

Q: How can I get a quote or sample?

A: Simply contact our sales team with your application details (flow rate, pressure, media, speed, etc.). We will assist with model selection and provide a competitive quote. Sample units can be arranged for testing. Our goal is to support your project from initial inquiry to long-term operation.

Get a Quote / Contact Us

Ready to enhance your hydraulic systems?

- Get a Quote: Send us your requirements and receive a tailored price and delivery schedule.

- Request a Sample: Test our rotary joint in your system. We’ll provide a demo unit for evaluation.

- Contact Technical Support: Our engineers are available for consultation on selection, installation, and maintenance.

Please reach out today to discuss your hydraulic rotary joint needs!