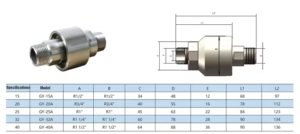

Inline 360 Degree Straight High Pressure Rotary Union

Original price was: $30.00.$24.00Current price is: $24.00.

- Maximum speed: 0-100 RPM

- Maximum pressure: 25 MPa

- Maximum temperature: 200 ℃

- Applicable media: gas, water, oil, air, etc.

Description

Inline 360 Degree Rotary Union – High-Performance Fluid and Air Transfer Solution

The Inline 360 Degree Rotary Union is a high-quality, durable component designed for efficient fluid or air transfer between rotating and stationary components. This high-pressure rotary joint is specifically designed for the dynamic connection of fluid media between rigid pipes, providing reciprocating or low-speed rotary motion. The design features high wear resistance and supports internal rotation with two rows of wide, deep groove ball bearings, ensuring flexible and smooth movement with strong support capacity. We can customize the connection dimensions to meet customer requirements. The seal uses German Obers seals, offering reliable sealing performance and a long service life. Ideal for use in machinery, automated systems, and high-speed equipment, it features a 360-degree rotation capability that allows for flexible installation and enhanced functionality.

Key Features of Inline 360 Degree Rotary Union

Wide, Deep Groove Ball Bearings

Equipped with large, wide, and deep groove ball bearings, ensuring smooth and stable operation without any wobble or instability. These bearings enhance performance and extend the service life of the rotary union, even under continuous rotational movement.

Smooth Operation with No Wobble

The design of the deep groove ball bearings ensures that the rotary union operates smoothly and evenly, eliminating any wobble or vibration. This results in reliable, consistent fluid and air transfer, enhancing system efficiency.

Pre-filled with Bearing Lubricant

The bearings are pre-filled with high-quality bearing grease, ensuring that they remain well-lubricated throughout their operation. This reduces wear and tear, minimizes maintenance needs, and ensures optimal performance over time.

Specialized Seals

The rotary union features custom-designed seals that provide superior protection against leakage, ensuring the safe and efficient transfer of fluids and air. These seals are crafted to withstand a wide range of operating conditions, enhancing the durability and reliability of the union.

Versatile Joint Configurations

The rotary union offers multiple joint configurations to accommodate complex on-site conditions and spatial constraints. Whether dealing with confined spaces or needing flexible rotation for fluid and air transfer, the union can be adapted to meet a variety of application requirements.

Applications of the Inline 360 Degree Rotary Union

Manufacturing Equipment: Facilitates fluid transfer in automated systems and assembly lines.

Car Wash Systems: Enable high-pressure water delivery for effective vehicle cleaning.

Industrial Cleaning Machines: Supports pressure washing and cleaning equipment requiring continuous fluid flow.

Hydraulic Systems: Ideal for hydraulic machinery that requires reliable fluid transfer during operation.

Advantages of using an Inline 360 Degree Rotary Union

Continuous Rotation

A 360-degree rotary union allows for uninterrupted rotation, enabling continuous movement without the need for stopping or repositioning. This feature actively benefits applications that require constant motion, such as robotic arms or automated machinery, by enhancing operational efficiency and ensuring smooth, uninterrupted performance.

Flexibility in Design

The 360-degree design provides greater installation flexibility, allowing for more versatile configurations in tight spaces. This adaptability can be crucial in complex machinery setups where space constraints are a concern, enabling better integration into existing systems.

Multiple Fluid Transfer

We can design many 360-degree rotary unions to accommodate multiple fluid pathways, enabling the simultaneous transfer of different fluids, such as hydraulic oil and coolant. This capability is advantageous in applications that require the management of various media without needing multiple unions.

Reduced Wear and Tear

With the ability to rotate continuously, 360-degree rotary unions help minimize friction and wear on components compared to 90-degree unions, which may experience more stress at the pivot point. This reduction in wear can lead to longer service life and lower maintenance costs.

Enhanced Performance in Dynamic Applications

In dynamic applications where equipment frequently changes direction or speed, a 360-degree rotary union provides superior performance by maintaining fluid flow without interruption. This feature is essential for high-speed operations, such as in manufacturing lines or automotive assembly.

Improved Safety

The design of a 360-degree rotary union can enhance safety by eliminating the risk of hose tangling or kinking that may occur with fixed-angle unions. This safety aspect is critical in environments where equipment mobility is essential, reducing the likelihood of accidents.

Higher Pressure Ratings

Many 360-degree rotary unions are engineered to handle higher pressure ratings compared to their 90-degree counterparts. This capability makes them suitable for more demanding applications, such as hydraulic systems that operate under high pressure.

Versatile Applications

The 360-degree rotary union proves versatile, making it ideal for use across various industries, including automotive, aerospace, and manufacturing. These industries rely on continuous fluid transfer, and the rotary union ensures smooth and efficient operation, meeting the demanding requirements of each sector. This adaptability makes it a preferred choice for many industrial applications.

Simplified Maintenance

Due to their design, many 360-degree rotary unions require less frequent maintenance than fixed-angle unions. The reduced complexity in managing fluid pathways can lead to easier servicing and lower operational interruptions.

Customizable Options

360-degree rotary unions often come with customizable features that can be tailored to specific application needs, including different connection types and sizes. This customization ensures that businesses can find solutions that fit their unique requirements effectively.

Order Now

Get your Inline 360 Degree Rotary Union today and take your machinery to the next level of performance and efficiency.