Machine Tool High Speed Rotary Union

Original price was: $60.00.$55.00Current price is: $55.00.

- Max Rotational Speed: Up to 42,000 RPM

- Max Pressure: Up to 250 bar

- Nominal Size: 0.1 in – 0.5 in

- Media Types: Supported Coolant, air, hydraulic oil

- Temperature Range: -20°C to 100°C

Description

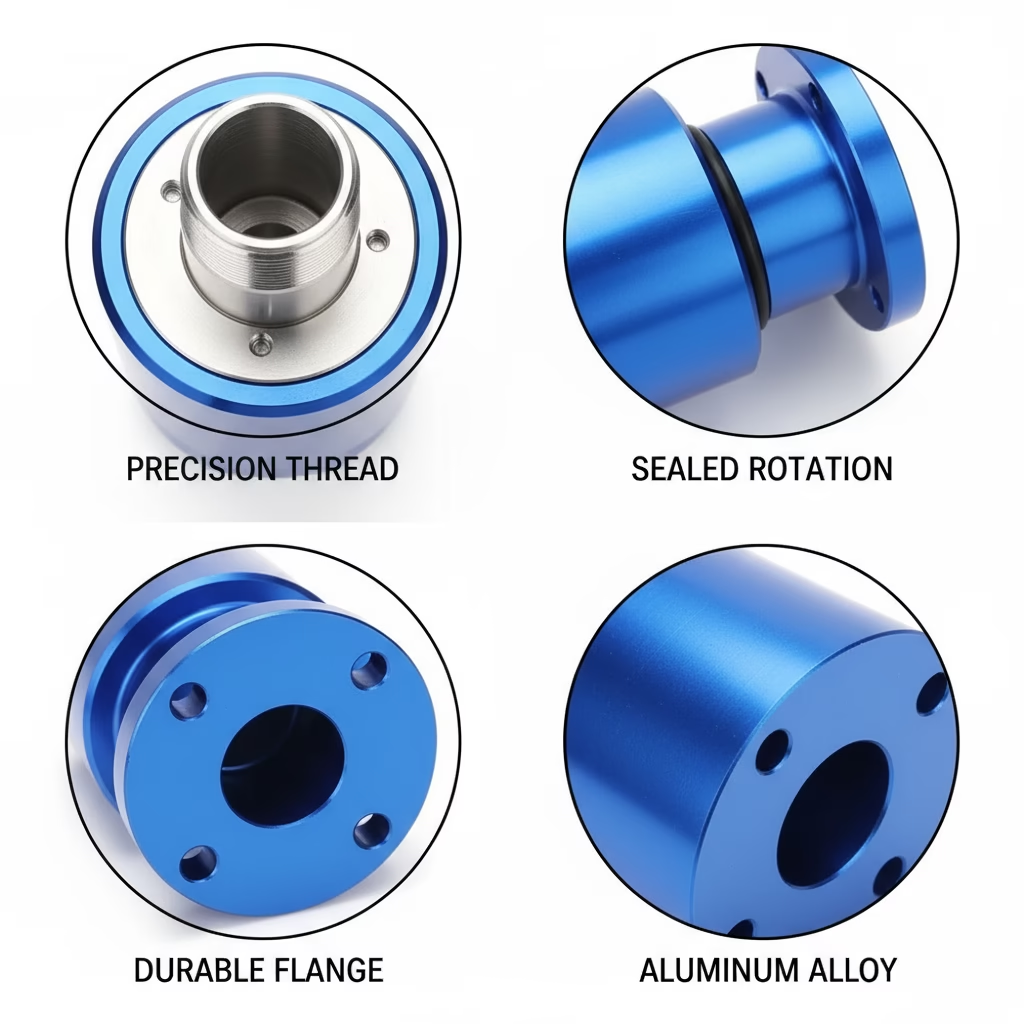

Product Overview: Machine Tool High-Speed Rotary Union

Introducing the Machine Tool High-Speed Rotary Union, a precision-engineered solution designed to optimize fluid transfer in high-performance machining applications. This rotary union is essential for ensuring efficient coolant and air delivery to rotating machinery, enhancing productivity and operational efficiency in various industrial settings. The Machine Tool High Speed Rotary Union is a critical component engineered for modern machine tools, enabling efficient transfer of coolant and other fluids to high-speed rotating spindles. Designed to support cutting-edge machining operations, this rotary union ensures optimal thermal management, lubrication, and operational reliability, even under the most demanding conditions.

| Parameter | Specification |

|---|---|

| Maximum Speed | Up to 24,000 rpm |

| Maximum Pressure | Up to 140 bar (2030 psi) |

| Flow Rate | Approx. 24.3 L/min (6.4 GPM) |

| Seal Material | Tungsten carbide / Silicon carbide |

| Body Material | Aluminum or Stainless Steel |

| Temperature Range | Up to 71°C (160°F) |

| Connection Sizes | 1/4", 3/8", M16x1.5 |

Machine Tool High Speed Rotary Union: Pain Points & Solutions

Pain Point 1: Leakage and Seal Failure

Problem: Leakage is the most common issue in rotary unions, often caused by worn or damaged seals, improper installation, or incompatible fluids. Leaks lead to coolant loss, spindle contamination, and potential machine downtime.

Solution: Our rotary unions feature advanced tungsten carbide or silicon carbide balanced seals that are micro-lapped for durability and low friction, significantly reducing leakage risks. Proper installation, following manufacturer guidelines, and using compatible coolants ensure long-lasting seal integrity and leak-free operation. Regular inspection and timely seal replacement prevent unexpected failures.

Pain Point 2: Excessive Wear and Bearing Damage

Problem: High-speed rotation and poor lubrication can cause premature wear on bearings and internal components, leading to noise, vibration, and eventual failure.

Solution: We use high-quality stainless steel bearings designed for high rpm operation and low friction torque. Our rotary unions support proper lubrication intervals and dry run capability, preventing damage during idle periods. Routine maintenance and filtration of coolant to 50 microns or finer protects bearings from abrasive particles.

Pain Point 3: Overheating and Temperature Issues

Problem: Overheating caused by high friction or inadequate coolant flow can damage seals and reduce union lifespan, affecting spindle performance.

Solution: Our design optimizes fluid flow channels and uses materials with excellent thermal conductivity. The unions maintain stable temperatures even at high speeds, supported by efficient coolant delivery systems. Monitoring operating conditions and using recommended coolants helps avoid temperature-related failures.

Pain Point 4: Noise and Vibration During Operation

Problem: Misalignment, imbalanced components, or worn bearings can cause excessive noise and vibration, impacting machining precision and equipment longevity.

Solution: Each rotary union is precision-balanced and assembled with tight tolerances to minimize vibration. Installation by qualified personnel following exact alignment procedures ensures smooth, quiet operation. Periodic alignment checks and bearing inspections maintain optimal performance.

Pain Point 5: Reduced Rotation Speed or Binding

Problem: Debris, improper lubrication, or mechanical obstruction can reduce rotation speed or cause binding, leading to machining errors and downtime.

Solution: Our unions feature smooth internal flow paths and dry run seals that prevent contamination buildup. Regular cleaning, proper lubrication, and filtration prevent blockages. Quick access for maintenance allows prompt removal of debris and ensures continuous high-speed operation.

Key Features of Machine Tool High Speed Rotary Union

Key Features of Machine Tool High Speed Rotary Union

Exceptional Speed Capability

Designed to operate at speeds up to 42,000 RPM, this union ensures rapid and efficient fluid transfer, making it ideal for high-speed machining processes.

High-Speed Capability

Engineered to withstand spindle speeds up to 24,000 rpm, the rotary union supports ultra-fast machining processes without compromising fluid delivery or seal integrity.

Versatile Media Compatibility

Capable of transferring a variety of media, including coolant, air, hydraulic oil, and other fluids, making it suitable for diverse industrial applications.

Balanced and Micro-Lapped Seals

The union uses advanced seals made from tungsten carbide or silicon carbide, micro-lapped to optical flatness, ensuring minimal friction, exceptional wear resistance, and long service life.

Versatile Fluid Compatibility

Suitable for water-based coolants, cutting oils, compressed air, Minimum Quantity Lubrication (MQL), and even dry air applications, providing flexibility across various machining environments.

Durable Construction

Featuring stainless steel rotors and aluminum or stainless steel housings, these unions offer corrosion resistance and robust mechanical strength.

Dry Run Capability

The seals remain closed and effective even when no fluid passes through (dry run), preventing contamination and damage during machine startup or idle periods.

Why Choose Our Machine Tool High Speed Rotary Union?

Our rotary unions are manufactured with precision engineering and rigorous quality control, ensuring:

- Reliable performance at extreme speeds and pressures.

- Extended service life with minimal downtime.

- Compatibility with a broad range of industrial fluids.

- Expert technical support and customization options.

Applications of Machine Tool High Speed Rotary Union

The high-speed rotary union is integral to numerous machine tool operations:

CNC Machining Centers

Facilitates the delivery of coolant and lubricants to cutting tools, enhancing tool life and machining accuracy.

Rotary Tables

Enables the transfer of hydraulic or pneumatic power to rotating fixtures, ensuring precise positioning and clamping.

Spindle Heads

Allows for the continuous supply of fluids to rotating spindles, maintaining optimal operating temperatures and reducing wear.

Drilling and Milling Machines

Ensures efficient chip removal and cooling during high-speed drilling or milling operations.

FAQ of Machine Tool High Speed Rotary Union

What is a Machine Tool High-Speed Rotary Union?

A Machine Tool High-Speed Rotary Union is a device that allows for the transfer of fluids, such as coolant or air, from a stationary source to a rotating component in high-speed machining applications. It is designed to operate at speeds often exceeding 20,000 RPM while maintaining pressure and preventing leaks.

What are the key applications of high-speed rotary unions in machine tools?

High-speed rotary unions are primarily used in CNC machines, lathes, milling machines, and robotic arms. They facilitate efficient coolant delivery and pneumatic air transfer, which are crucial for maintaining optimal tool performance and extending tool life during machining processes.

How do high-speed rotary unions improve machining efficiency?

By providing a continuous supply of coolant or air at high speeds, these rotary unions help reduce tool overheating and wear, enabling faster feed rates and improved machining accuracy. This leads to higher productivity and better-quality finished products.

What materials are commonly used in the construction of rotary unions?

High-speed rotary unions are typically made from durable materials such as brass, aluminum, stainless steel, and specialized polymers for seals. These materials provide corrosion resistance and durability necessary for high-pressure and high-speed applications.

What is the maximum pressure rating for machine tool rotary unions?

Most machine tool high-speed rotary unions can handle pressure ratings ranging from 100 bar (approximately 1450 PSI) to 250 bar (approximately 3625 PSI), depending on the specific model and design intended for different applications.

Can high-speed rotary unions operate in dry run conditions?

Yes, many modern designs allow for dry run operation, meaning they can function effectively without fluid passing through. This feature is particularly useful in applications where intermittent operation without media is necessary.

What innovations are currently influencing the design of rotary unions?

Innovations include advancements in seal technology (such as tungsten carbide seals), improved bearing designs for reduced friction, and integrated systems that combine electrical slip rings with rotary unions for more efficient data and media transfer.

How do you select the right high-speed rotary union for your application?

When selecting a rotary union, consider factors such as operating speed, pressure requirements, fluid type (coolant or air), temperature range, and specific mounting configurations. Consulting with manufacturers can provide insights into custom solutions tailored to specific needs.

What maintenance practices are recommended for high-speed rotary unions?

Regular inspection for leaks and wear on seals is essential for maintaining performance. Lubrication of bearings may also be necessary, depending on the design. Following manufacturer guidelines will help ensure longevity and reliability.

What are the benefits of using a machine tool rotary union over traditional methods?

The use of unions enhances operational efficiency by allowing continuous fluid transfer without interruptions caused by manual connections or disconnections. They also reduce wear on components, decrease maintenance needs, improve safety by preventing leaks, and enable higher precision in machining operations.

Conclusion

Conclusion

The Machine Tool High Speed Rotary Union represents a paradigm shift in CNC machining, combining high-speed dynamics, intelligent monitoring, and modular flexibility. As industries transition toward smart manufacturing, this product stands as a cornerstone for achieving micron-level precision, energy efficiency, and operational reliability. For manufacturers aiming to lead in Industry 4.0, adopting this technology is not merely an upgrade—it’s a strategic imperative.