Durable Rotary Union with Dynamic Mechanical Sealing System

Original price was: $70.00.$62.00Current price is: $62.00.

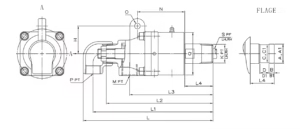

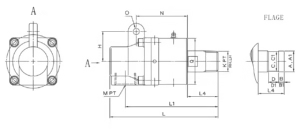

- Connection: Thread/The flange

- Product name: Water Hot Water Hot Oil mechanical seals rotary union

- Color: Can be customized

- Medium: water, hot oil

- Size: 20 32 40 50 65 80

- Surface treatment: spray paint

- Thread: BSPP BSPT NPT METRIC

- Max Speed: 750~2000RPM

- Max Temperature: 235℃

- Max Pressure: 10kg/cm*cm

Description

Product Overview

Our Mechanical Seals Rotary Union delivers superior sealing performance in high-speed rotating systems. Designed for durability and leak-proof operation, this rotary union is ideal for applications involving water, oil, steam, air, and other media. It integrates a high-precision mechanical seal system with advanced rotary sealing technology, ensuring stable operation under high pressure and extreme temperatures. Designed for seamless integration with pumps, mixers, centrifuges, and other rotating machinery, this rotary union features advanced mechanical seals that prevent fluid leakage, reduce downtime, and enhance equipment longevity.

Whether you’re upgrading rotating machinery, maintaining a manufacturing line, or designing a new piece of industrial equipment, this component provides efficient fluid transfer without compromising performance or safety.

Key Features

Reliable Mechanical Seal Technology

Our rotary unions are equipped with high-performance mechanical seals that maintain a consistent, leak-free seal between stationary and rotating components. This design is ideal for handling high-pressure and high-speed fluid transfer applications, ensuring extended service life with minimal maintenance.

Wide Media Compatibility

Compatible with a broad range of media, including water, steam, oil, coolant, hydraulic fluid, and air. The mechanical seal materials (such as carbon vs. ceramic, silicon carbide, or tungsten carbide) are selected based on media type and working temperature, offering excellent chemical resistance.

High Pressure and Temperature Resistance

Designed to operate under pressures up to 150 bar (2175 psi) and temperatures exceeding 200°C (392°F), making them ideal for demanding industrial environments such as steel, plastics, and paper manufacturing.

Versatile Design Options

Available in single-flow and dual-flow passages, with customizable port sizes (NPT, BSP, metric threads), housing materials (stainless steel, brass, aluminum), and mounting types (flange, threaded, foot-mount). This modular approach ensures easy integration into both OEM and retrofit systems.

Long Service Life and Low Maintenance

Thanks to precision-engineered seal faces and balanced seal loading, our mechanical seals and rotary unions reduce wear and friction, lowering maintenance requirements and operating costs over time.

Corrosion-Resistant Construction

Housing options in marine-grade stainless steel, anodized aluminum, or nickel-plated brass provide excellent protection in corrosive or wet environments, ideal for food processing, chemical plants, or offshore applications.

High-Speed Operation

Engineered with precision bearings and dynamic balancing for smooth performance at rotational speeds of up to 10,000 RPM, depending on size and media. Ideal for high-speed CNC machining and spindle cooling systems.

Application

Paper and Pulp Industry

Used in rotary steam cylinders and drying sections of paper machines.

Ensures continuous fluid transfer while withstanding high temperatures.

Helps prevent leakage and fiber contamination during paper processing.

Textile Dyeing and Finishing Equipment

Enables smooth transfer of steam and hot oil to rotating drums.

Maintains sealing performance under fluctuating pressure and rotation.

Improves dyeing uniformity and equipment reliability in textile plants.

Printing Presses

Provides leak-proof rotary sealing for ink and cooling systems.

Supports high-speed rotation essential for print consistency.

Reduces downtime caused by seal failure or fluid leaks.

CNC Machines and Rotary Tables

Transfers coolant or hydraulic oil to high-speed rotating tools.

Maintains tight sealing even at 5000+ RPM rotational speeds.

Prevents fluid loss that could affect machining precision.

Chemical and Pharmaceutical Equipment

Handles transfer of aggressive fluids in rotating reactors.

Mechanical seal materials resist chemical corrosion and abrasion.

Supports hygienic and leak-free processing for sensitive products.

Construction and Mining Equipment

Used in excavators, drilling rigs, and rotary joints for hydraulics.

Delivers fluid power between the stationary base and the rotating boom.

Withstands harsh outdoor environments and heavy-duty cycles.

Wind Turbines

Transfers hydraulic fluids to the pitch control and yaw system.

Works in a remote environment, rotating components exposed to temperature changes.

Prevents oil leakage and ensures continuous turbine operation.

Food and Beverage Processing

Used in rotary cookers, mixers, and sterilizers for steam/oil.

Constructed with FDA-compliant materials for hygiene compliance.

Delivers consistent heating or cooling in sanitary environments.

Plastic Injection Molding Machines

Provides rotary sealing for hot oil or water in mold temperature control.

Prevents leaks that could affect plastic product quality.

Supports high-speed cycling under precise temperature regulation.

Rubber and Tire Manufacturing

Used in calendar rolls and rotary drums for curing and shaping.

Handles high pressures and abrasive materials in tire processes.

Improves product uniformity and reduces maintenance downtime.

Benefits

Extended Service Life

The combination of advanced seal technology and durable materials significantly increases the lifespan of the rotary union, reducing the frequency of replacements and maintenance.

Low Maintenance Requirements

Designed for ease of use, our rotary unions feature on-machine seal replacement capabilities. This allows for quick servicing without removing the entire unit from the machinery, minimizing downtime.

High Operational Efficiency

With a maximum operating temperature of 500°F (260°C) and pressure ratings up to 360 psi (25 bar), our rotary unions are engineered to perform efficiently in demanding applications while maintaining a low pressure drop.

Customizable Solutions

We understand that every application is unique. Our rotary unions can be customized to meet specific requirements regarding size, sealing materials, and configurations to ensure optimal performance in your operational environment.

FAQ

Q1: Can this rotary union handle abrasive fluids?

A1: Yes, the mechanical seals are designed with durable materials suitable for handling mildly abrasive fluids. For highly abrasive media, please consult our technical team.

Q2: Is this rotary union suitable for food-grade applications?

A2: Absolutely. We offer sanitary-grade versions compliant with FDA and EHEDG standards.

Q3: How do I know which connection type to choose?

A3: Choose based on your existing system fittings—threaded for easy replacement, flanged for heavy-duty connections, or quick-connect for fast maintenance.

Enhance Your Industrial Process with Our Mechanical Seals Rotary Union

Invest in a mechanical seal rotary union that guarantees reliability, durability, and efficiency. Whether you operate in chemical processing, manufacturing, or food production, our rotary union ensures smooth, leak-free fluid transfer in rotating equipment.

Order now to experience superior sealing technology and elevate your system’s performance!