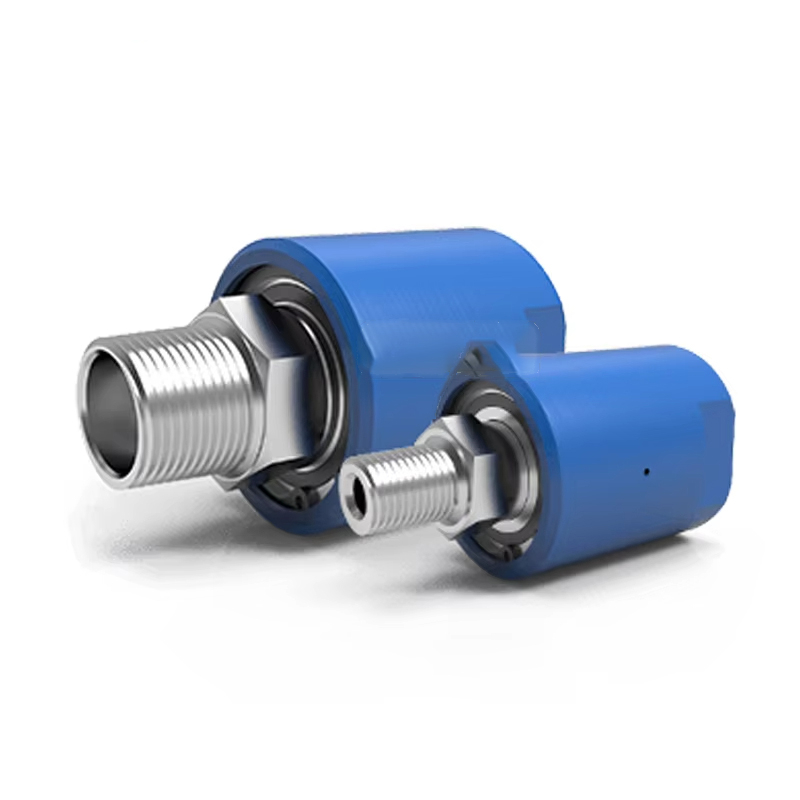

Pneumatic Rotary Union

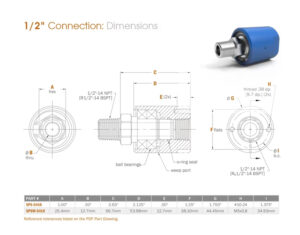

- Max Pressure: Up to 10 bar (145 psi)

- Max Temperature: Up to 80°C (176°F)

- Rotational Speed: Up to 3,000 RPM

- Materials: Stainless Steel, Carbon Graphite Seals

- Seal Type: Balanced Mechanical Seals

Description

Product Overview: Pneumatic Rotary Union

Introducing our Pneumatic Rotary Union, a vital component engineered for the seamless transfer of compressed air and gases between stationary and rotating machinery. Designed to enhance operational efficiency across various industrial applications, this rotary union ensures a continuous and leak-free flow while accommodating the dynamic movements of equipment.

Key Features

Key Features

Uninterrupted Airflow: Our pneumatic rotary unions are designed to provide a constant supply of compressed air or gas, allowing for continuous operation without interruptions. This feature is crucial in high-speed applications where downtime can significantly impact productivity.

Robust Construction: Built with high-quality materials such as stainless steel and advanced sealing technologies, our unions are engineered for durability and reliability in demanding environments.

Versatile Media Compatibility: Capable of handling not only air but also other gases and mixed media, these rotary unions are ideal for applications requiring flexibility in media transfer.

Applications

Manufacturing: Essential for pneumatic tools and robotic arms, providing a reliable supply of compressed air to enhance productivity on assembly lines.

Automotive Industry: Used in operating rotary tables and other pneumatic controls, ensuring precise operation in automotive manufacturing processes.

Textile Industry: Facilitates the operation of winders and textile machines by supplying consistent airflow for fabric rolling and processing.

Printing Industry: Integral to printing presses, where they maintain the functionality of pneumatic controls and regulate temperatures for optimal performance.

Food Processing: Supports equipment that requires pneumatic control systems for packaging and processing applications.

Benefits

Enhanced Operational Efficiency: By enabling seamless air transfer without the need for disconnection during rotation, our pneumatic rotary unions reduce downtime and improve overall system performance.

Safety Assurance: The robust design minimizes the risk of leaks, enhancing safety in environments where pressurized gases are used.

Easy Maintenance: Features such as external seal wear indicators allow for proactive maintenance scheduling, reducing unexpected downtime. Why Choose Our Pneumatic Rotary Union?

Why Choose Our Pneumatic Rotary Union?

Our Pneumatic Rotary Union is meticulously crafted to meet the rigorous demands of modern industrial applications. With a focus on reliability, efficiency, and performance, this product not only adheres to industry standards but also enhances operational capabilities across various sectors. What is a pneumatic rotary union?

What is a pneumatic rotary union?

A pneumatic rotary union is a mechanical device that enables the transfer of compressed air or gases between stationary and rotating components. It allows for continuous operation without the need for disconnection, ensuring a reliable and uninterrupted airflow in various industrial applications.

What are the key applications of pneumatic rotary unions?

Manufacturing: For pneumatic tools and robotic arms.

Automotive: In assembly lines for operating pneumatic controls.

Textile: To facilitate the operation of winders and other machinery.

Food Processing: In packaging machines that require pneumatic control.

How do pneumatic rotary unions prevent leaks?

These unions utilize advanced sealing technologies, such as balanced mechanical seals made from materials like carbon graphite, to create a robust barrier against leaks. This design minimizes the risk of air escape, ensuring safe operation in high-pressure environments.

What are the advantages of using pneumatic rotary unions?

Continuous Airflow: They provide a constant supply of compressed air, enhancing productivity.

Durability: Constructed from high-quality materials, they are designed to withstand harsh operating conditions.

Versatility: Capable of handling various gases and media types, making them adaptable to different applications.

What maintenance practices are recommended for pneumatic rotary unions?

Regular inspections for wear on seals and bearings.

Monitoring for leaks or pressure drops.

Ensuring proper lubrication where applicable.

Scheduling proactive maintenance based on wear indicators.

Can pneumatic rotary unions be customized for specific applications?

Yes, many manufacturers offer customizable solutions tailored to meet specific operational requirements, including variations in size, pressure ratings, and seal types to suit unique applications across different industries.

What materials are commonly used in pneumatic rotary unions?

Pneumatic rotary unions are typically constructed from durable materials such as stainless steel or aluminum for the body, with advanced sealing materials like carbon graphite or elastomers that provide resistance to wear and temperature extremes.

How do pneumatic rotary unions integrate with other systems?

Many pneumatic rotary unions can be combined with electrical slip rings or fiber optic rotary joints to allow simultaneous transfer of power or data alongside compressed air. This integration is crucial in applications where both fluid transfer and data communication are required.

What innovations are emerging in the design of pneumatic rotary unions?

Recent innovations include enhanced sealing technologies that improve durability under extreme conditions, designs that allow for higher rotational speeds, and smart monitoring systems that provide real-time performance data for proactive maintenance management.

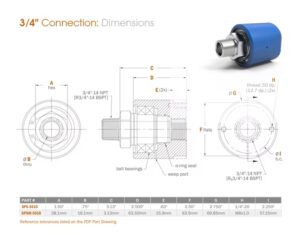

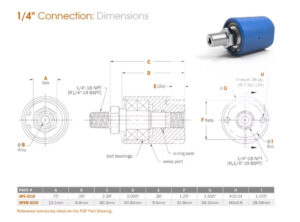

What factors should be considered when selecting a pneumatic rotary union?

When choosing a pneumatic rotary union, consider factors such as:

Operating pressure and temperature requirements.

Rotational speed capabilities.

The specific media being transferred (e.g., compressed air or gases).

Compatibility with existing systems and installation requirements.