Tool Center Outlet High Speed Rix Rotary Union

Original price was: $110.00.$106.00Current price is: $106.00.

- Max Speed: 5,000 RPM

- Max Temperature: 60 °C (140 °F)

- Max Pressure: 10 bar (145 psi)

- Fluid Type: Coolant oil (VG10)

Description

RIX Rotary Union: Product Overview

The RIX Rotary Union is a cutting-edge solution designed for efficient fluid transfer in various industrial applications. Engineered for high performance and reliability, this rotary union is particularly well-suited for ball screw cooling and other applications requiring precise coolant management. With its innovative design and advanced features, the RIX Rotary Union enhances operational efficiency while minimizing energy consumption.

Key Features of Rix Rotary Union

Key Features of Rix Rotary Union

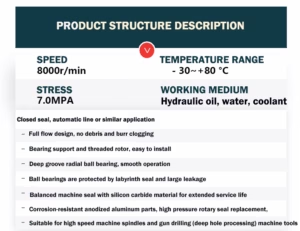

Breakthrough in speed and pressure resistance

RIX rotary joints increase the normal working speed to 15,000/min through the built-in bearing structure design, and some models (such as LA-1P02) can reach 50,000/rpm under specific configurations. At the same time, its pressure resistance range covers 7-20MPa, far exceeding the industry average. Taking the LX84-7920 model as an example, this product is designed for machine tool spindle cooling scenarios. It can withstand 0.5-7MPa pressure in cutting fluid delivery to ensure a stable supply of coolant during high-speed cutting.

Innovation in sealing technology

Silicon carbide sealing material is used, which has wear resistance and automatic lubrication performance, supports ultra-high-speed dry operation and high-pressure coolant environment, and can achieve leakage-free operation under ultra-high-speed dry operation (such as ESX20M series) and high-pressure coolant environment (such as L40 series). Test data shows that under a pressure of 20MPa, its leakage is far lower than the industry standard.

Modular design to adapt to complex working conditions

RIX provides diversified solutions for different media requirements. It covers machine tool spindle cooling (supported by models such as LA-1P02 and LX86V-244C), semiconductor manufacturing (L40/MFES series), floating oil recovery, and other scenarios, meeting the transportation requirements of different media (cutting fluid, oil, dry air, pure water, etc.).

Bearing technology breakthrough

The built-in bearing structure design improves maintainability and service life, and solves vibration and leakage problems during horizontal use.

Application

Application

CNC machining center

In high-speed cutting scenarios, RIX rotary joints can withstand a speed of 50,000 r/min, ensuring that the cutting fluid is delivered to the spindle at a constant pressure to avoid tool chipping due to insufficient cooling.

Semiconductor manufacturing

The L40/MFES series rotary joints control the amount of metal ion dissolution at the ppb level through the non-metallic main channel design, meeting the ultra-clean requirements for pure water and chemical solution delivery.

Oil drilling

In drilling equipment, RIX rotary joints can withstand high-pressure and high-temperature environments, ensuring the stability of power transmission and signal control, and reducing the risk of drilling accidents.

Floating oil recovery system

The MOS series rotary joints use a spiral design to achieve efficient floating oil recovery in harsh environments such as sludge and slag, and the continuous working recovery volume can reach 100 ml/hr.

Benifits

1. Dual guarantee of efficiency and quality

In the scenario of center water discharge of the machine tool spindle, the RIX rotary joint can achieve:

Reduce the iron chip winding rate by 80%

Through continuous coolant supply, metal debris generated during processing can be effectively removed.

Extend tool life by 30%

Center water discharge technology reduces the temperature of the cutting area and reduces tool wear caused by high temperatures.

Improve the surface finish of parts.

Stable coolant flow ensures processing accuracy and enhances product market competitiveness.

2. Reduce maintenance costs throughout the whole cycle

Reduce maintenance costs by 50%

The embedded design of bearings significantly improves the maintainability and replaceability of rotary joints, reducing downtime caused by bearing damage.

Reduce energy consumption by 20%

In the scenario of floating oil recovery, the RIX inner shaft rotary floating oil recovery machine (such as the MOS series) uses a spiral design to achieve efficient recovery in harsh environments such as sludge and slag.

3. Adapt to harsh working conditions and meet high industry standards

- In harsh environments such as oil drilling and oil recovery, RIX rotary joints can withstand high pressure, high temperature, or complex working conditions such as oil sludge and slag, ensuring the stable operation of the equipment.

- In semiconductor manufacturing, the L40/MFES series rotary joints control the amount of metal ion dissolution at the ppb level through the non-metallic main channel design, meeting the requirements of an ultra-clean environment.

Installation Requirements for the RIX Rotary Union in Vertical Applications

Orientation

The RIX Rotary Union can be installed in both vertical and horizontal orientations. However, if installed vertically, the rotor should ideally point downward to prevent potential damage. Installing with the rotor pointing upward may lead to component failure due to fluid accumulation or leakage issues.

Connection of Hoses

Flexible Hoses: Always use flexible hoses for connecting the rotary union to avoid stress on the unit. This flexibility helps accommodate any movement and prevents lateral loads on the bearings, which can lead to premature wear.

Hose Installation: Ensure that hoses are installed without stress or bends. They should be routed in a way that allows for easy drainage of any leakage, particularly when the rotary union is positioned vertically.

Leakage Management

Install a leakage or ventilation line to manage any function-related leakage that may occur during operation. This line should be positioned at the lowest point of the installation to facilitate proper drainage.

If connecting hoses from above, consider installing a check valve (with a switching pressure of less than 0.5 bar) near the rotary union to prevent backflow during operation.

Pressure and Residual Pressure Checks

Before installation, ensure that there is no feed pressure or residual pressure in the pipeline system of the machine. This precaution is critical for safe and effective installation.

Axial Force Considerations

Be aware of axial forces that may need to be absorbed by spindle bearings, especially in housing-supported models. The medium pressure at the effective diameter can create additional axial forces that must be accounted for during installation.

Installation Manual Reference

Always refer to the model-specific installation manual provided with the RIX Rotary Union for detailed instructions tailored to your specific model. This manual includes vital information regarding connection configurations and operational guidelines.

FAQ

What are the RIX Rotary Unions?

The RIX Rotary Unions are a specialized component designed for efficient fluid transfer in rotating applications. It is widely used in various industries, including machine tools, automotive, and rubber manufacturing, to provide reliable coolant and lubrication flow while minimizing wear and tear on machinery components.

How do the RIX Rotary Unions improve machine performance?

The RIX Rotary Unions enhance machine performance by ensuring continuous and efficient fluid transfer, which helps maintain optimal operating temperatures and reduces friction. This leads to improved tool life, reduced energy consumption, and overall higher productivity in manufacturing processes.

What industries commonly use the RIX Rotary Unions?

Industries that benefit from the RIX Rotary Unions include: Machine Tool Manufacturing, Automotive Production, Rubber and Tire Manufacturing, Paper and Pulp Processing, and Steel Production. These sectors utilize the rotary union for its reliability in fluid management under demanding conditions.

How does the design of the RIX Rotary Unions contribute to its durability?

The RIX Rotary Unions feature robust construction with high-quality materials designed to withstand high speeds and pressures. Its sealing technology minimizes leaks and wear, ensuring long-lasting performance even in harsh operating environments.

Can the RIX Rotary Unions handle dry running conditions?

Yes, certain models of the RIX Rotary Unions are designed to handle dry running conditions effectively. This capability allows for operation without fluid under specific circumstances, making it versatile for applications.

How do the RIX Rotary Unions compare to other rotary unions?

The RIX Rotary Unions are known for their high-speed capabilities, robust construction, and versatility across different fluids compared to other rotary unions.