Corrugated Cardboard Machine Part Rotary Joint for Steam

Original price was: $40.00.$30.00Current price is: $30.00.

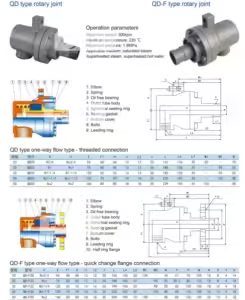

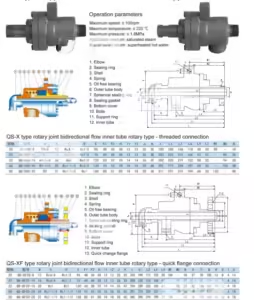

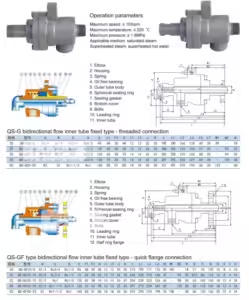

- Connection: Thread/The flange

- Product name: Hot Oil Steam Rotary Joint

- Color: Can be customized

- Medium: Hot water vapor, Steam

- Size: 1/2″~4″

- Surface treatment: Spray paint

- Thread: BSPP BSPT NPT METRIC

- Max Speed: 100RPM

- Max Temperature: 220℃

- Max Pressure: 1.8mpa

Description

A Corrugated Cardboard Machine Part Rotary Joint for Steam is a specialized mechanical device used to transfer steam from a stationary supply pipe into a rotating component—typically a heated roll—within a corrugated cardboard production line. Also known as a steam rotary union, this component plays a critical role in maintaining consistent heat distribution, ensuring proper adhesion and drying of the cardboard layers.

In the corrugation process, steam is used to heat various rollers, including corrugating rolls, preheaters, preconditioners, and double-facer rolls. These heated rollers apply the necessary temperature and pressure to shape the fluted medium, bond it with linerboard, and dry the final product. Because many of these rollers rotate continuously, a rotary joint is essential to allow the steam to flow into them without leaking, while still permitting free rotation.

The rotary joint seals the interface between the stationary steam line and the rotating roll. It ensures a leak-free, pressurized steam flow to the rotating part and, in some configurations, also allows for the return of condensed steam (condensate) via a dual-flow system.

| Specification | Detail |

|---|---|

| Media | Steam |

| Temperature Range | Up to 200°C (392°F) |

| Working Pressure | Up to 16 bar |

| Speed Range | Up to 300 RPM |

| Seal Type | Carbon Graphite / SiC |

| Body Material | Brass / Stainless Steel / Iron |

| Thread/Flange Options | BSP, NPT, DIN, ANSI |

Key Features

High-Temperature Resistance

Built to withstand saturated and superheated steam up to 250°C (482°F), with pressure ratings up to 20 bar, ensuring stable operation in demanding environments.

Durable Seal Technology

Equipped with precision carbon-graphite or silicon carbide seals that ensure long life, low friction, and exceptional thermal stability even under high-speed rotation.

Self-Supporting Design

Available in both supported and self-supported options to suit various roller lengths and mounting configurations.

Corrosion-Resistant Construction

Constructed from stainless steel, cast iron, or bronze alloys with anti-corrosion surface treatment for longevity in humid or chemically aggressive environments.

Dual-Flow or Single-Flow Options

Choose between a single passage for standard steam service or dual passage models for simultaneous steam inlet and condensate return.

High-Speed Capability

Designed for speeds up to 300 RPM, enabling use in fast-running corrugator lines without compromising joint integrity.

Applications

The Corrugated Cardboard Machine Part Rotary Joint for Steam plays a critical role in the corrugated paperboard production industry, particularly in systems that require efficient and reliable steam transmission between stationary piping and rotating machinery components.

1. Corrugator Dryer Sections (Heating Drums)

In single-facer and double-facer lines, rotary joints are installed on rotating drying drums or hot plates to supply and regulate steam.

They ensure even heat distribution across the drum surfaces, which is essential for consistent paperboard quality.

The rotary joint enables continuous rotation of the drums without steam leakage, improving operational safety and drying efficiency.

2. Preheater & Preconditioner Units

Steam rotary joints are used in preheater rolls to pre-warm the liner or medium paper before it enters the corrugating roll.

This improves adhesive bonding and reduces warpage or delamination in the finished board.

Precise steam control through the joint helps optimize moisture levels, improving board strength and flatness.

3. Double Backer Sections

Rotary joints are installed on steam-heated plates in the double backer to maintain the correct temperature required to bond the liner and medium under pressure.

Consistent heating leads to stable gluing performance and uniform board thickness.

4. Steam Distribution Manifolds & Condensate Return Systems

Used as a key link between steam headers and rotating units in the system.

The rotary joint allows for condensate return in dual-flow systems, improving steam cycle efficiency and energy savings.

5. Single Facer Corrugators

These systems use rotary joints on the corrugating rolls to maintain high-speed steam heating, ensuring proper flute formation and paper shaping.

Benefits in Real-World Applications

🌀 Stable Rotation at High Temperatures

Keeps your rolls rotating smoothly under intense thermal load.

⚙️ Minimized Steam Leakage

Sealing technology ensures tight control and long service intervals.

📏 Improved Dimensional Accuracy of Boards

Even heat means fewer defects and greater consistency.

💰 Energy Efficiency & Reduced Downtime

Proper steam usage leads to energy savings and fewer breakdowns.

In short, whether you’re producing 3-ply, 5-ply, or 7-ply corrugated boards or using semi-automatic or fully automatic production lines, our steam rotary joint ensures that your system operates with optimal heat transfer, minimal maintenance, and maximum productivity.

Why Choose Our Steam Rotary Union?

Our steam rotary unions stand out due to their robust construction and adaptability across various industries. With a commitment to excellence in product quality and customer service, we ensure that our solutions not only meet but exceed industry standards.

🔩 OEM & Customization Available

We offer custom sizes and configurations to meet your specific corrugator equipment requirements.

⚙️ Reliable Performance

Designed to operate under 24/7 continuous working conditions.

🌍 Global Shipping

Fast delivery to Asia, Europe, North America, and more.

🔧 Technical Support

Installation guidance and operational consultation are provided by our engineers.

🛡️ Quality Guarantee

ISO 9001 certified production process and strict quality control.

FAQ

FAQ

Q1: How do I know which rotary joint model fits my corrugator machine?

A: Simply provide us with details such as steam pressure, temperature, rotation speed, connection size, and application type. Our engineers will recommend a suitable model.

Q2: Can you supply custom rotary joints for specific equipment?

A: Yes. We support full OEM customization for flange type, material, and sealing technology according to your drawing or parameters.

Q3: Is the rotary joint suitable for continuous high-temperature operation?

A: Absolutely. Our rotary joints are designed to withstand 24/7 steam exposure at high temperature and pressure, perfect for corrugating lines.

Q4: What’s your minimum order quantity (MOQ)?

A: We accept small trial orders. MOQ can be as low as 1 piece for standard models.

Q5: Do you provide installation support?

A: Yes, we offer technical guidance via video or PDF, and on-site support is available for bulk orders.

A Corrugated Cardboard Machine Part Rotary Joint for Steam may be a small component, but its impact on the corrugating process is significant. It ensures the precise delivery of steam to rotating rollers, helping you maintain board quality, machine uptime, and production efficiency.

If you’re in the packaging or paperboard industry, using the right rotary joint can greatly influence your plant’s performance. Investing in high-quality, well-engineered rotary unions ensures reliability, energy savings, and long-term cost reduction.

📞 Contact Us Now

For premium Corrugated Cardboard Machine Part Rotary Joint for Steam, send us an inquiry today!

We guarantee fast response, competitive pricing, and technical expertise to support your corrugator production success.