Cost-Effective Rotary Unions for Rubber and Plastic Machine

Original price was: $175.00.$153.60Current price is: $153.60.

- Media: Water, oil, steam, hot oil, and other media used in molding processes

- Temperature: Ambient to +260°C (+500°F)

- Pressure Rating: Up to 345 bar (5,000 psi) or higher, depending on the model

- Rotational Speed: Up to 1,500 rpm

- Corrosion Resistance: Constructed from stainless steel and specialized alloys

Description

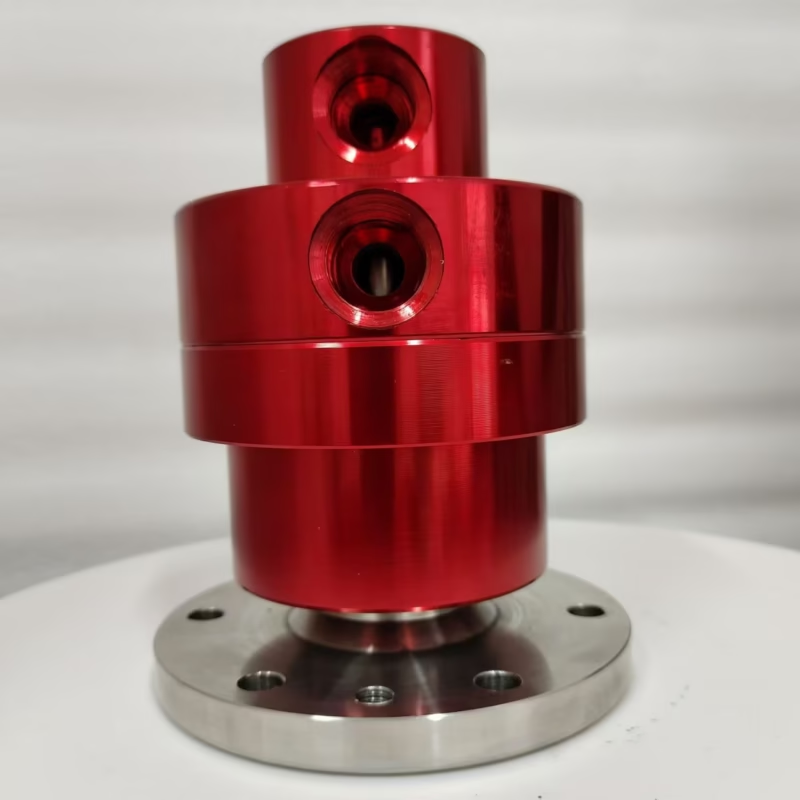

Rotary Union for Rubber and Plastic Molding Machine Product Overview

The Rotary Union for Rubber and Plastic Molding Machine is a precision-engineered component designed to transfer steam, water, oil, or cooling media into and out of rotating molds with maximum efficiency. Whether you are working in rubber injection molding machines, plastic extrusion equipment, or thermoforming systems, this rotary union delivers leak-free, high-performance fluid transfer under demanding temperature and pressure conditions.

Manufactured to meet international quality standards, this rotary joint is the ideal alternative to premium global brands, offering reliable performance at a more competitive price. Engineered with durable seals, advanced bearing support, and corrosion-resistant materials, it ensures long service life and minimizes downtime in production lines.

Key Features of Rotary Union for Rubber and Plastic Molding Machines

High-Performance Sealing Technology

Utilizes carbon graphite, ceramic, or hard-alloy seals for superior wear resistance.

Provides leak-proof operation in applications involving hot oil, steam, or cooling water.

Extends service intervals by reducing maintenance requirements.

Versatile Fluid Compatibility

Suitable for hot oil, steam, cooling water, compressed air, and hydraulic fluids.

Withstands a wide range of temperatures (up to 300°C / 572°F) and pressures (up to 25 bar).

Ideal for demanding rubber vulcanization and plastic molding processes.

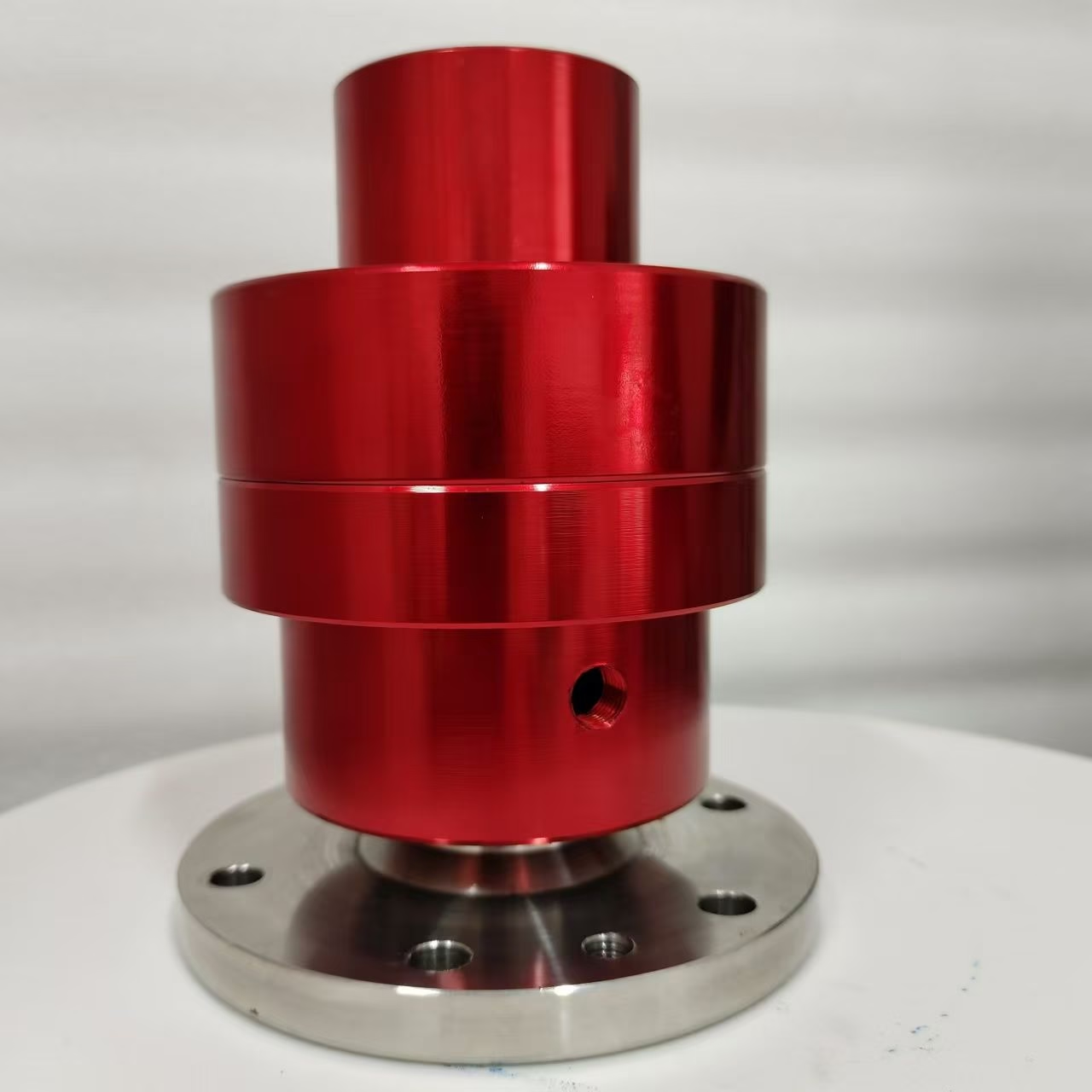

Heavy-Duty Construction

Built with stainless steel, ductile iron, or carbon steel housings for corrosion protection.

Internal components engineered for high-speed rotation and continuous duty cycles.

Extended service life ensures lower total cost of ownership.

Easy Installation & Maintenance

Available with threaded, flanged, or custom connections to fit multiple molding machine models.

Compact design allows for easy integration into existing systems.

Modular construction makes seal and bearing replacement simple.

Wide Application Range

Designed specifically for:

Rubber injection molding machines

Plastic compression molding machines

Thermoforming equipment

Extrusion lines

Rubber vulcanization presses

Ensures continuous and precise heat transfer for consistent product quality.

Application of Rotary Union for Rubber and Plastic Molding Machines

The Rotary Union for Rubber and Plastic Molding Machine is widely used across the rubber and plastics industry, where precise heat transfer and reliable fluid circulation are essential for ensuring mold accuracy, product consistency, and process efficiency. Below are the most common application scenarios:

Rubber Injection Molding Machines

Rotary unions are critical in rubber injection molding, where they transfer steam or hot oil into the mold to cure rubber products. Consistent heating ensures accurate shaping, uniform crosslinking, and long-lasting performance of rubber parts such as seals, gaskets, and industrial components.

Tire Vulcanization Presses

In tire manufacturing, the rotary union delivers high-pressure steam to the curing molds and removes condensate. This guarantees precise vulcanization, resulting in tires with superior strength, elasticity, and wear resistance.

Plastic Injection Molding Machines

For plastic injection molding, rotary unions circulate cooling water or thermal oil within the mold channels. This stabilizes mold temperatures, shortens cycle times, and ensures dimensional accuracy for components like automotive parts, electronic housings, and consumer products.

Plastic Compression Molding

In compression molding of thermoset plastics, rotary unions provide reliable transfer of heat transfer oil and cooling fluids, enabling uniform curing of complex-shaped components such as electrical insulators and structural composites.

Thermoforming Machines

Rotary joints regulate hot oil heating and water cooling in thermoforming molds, ensuring plastic sheets can be shaped accurately into trays, containers, and packaging materials without warping or dimensional defects.

Extrusion and Calendering Lines

Rotary unions supply cooling water and thermal oil to the extrusion dies and calender rolls. This keeps processing temperatures under control, resulting in smooth surfaces, stable output, and reduced scrap in plastic films, sheets, and rubber sheets.

Die-Casting Machines

In aluminum and zinc die-casting machines, rotary unions handle the circulation of oil and cooling fluids to maintain die temperatures. This prevents cracking, enhances surface finish, and prolongs die life.

Rubber Sheet Molding & Press Lines

In heavy-duty rubber molding presses, rotary joints manage steam heating and water cooling cycles, ensuring thick rubber sheets are cured evenly, avoiding internal stresses and defects.

Cooling Circuits in Rotating Machinery

Apart from molding, these rotary unions are used in auxiliary rotating equipment, transferring coolant or hydraulic oil in spindles, rollers, and rotating shafts.

Heat Transfer Systems in Manufacturing Automation

Many automated molding and forming machines rely on rotary joints for fluid circulation, enabling stable operation, lower downtime, and improved overall equipment efficiency (OEE).

👉 In short, the Rotary Union for Rubber and Plastic Molding Machine plays a decisive role in temperature control, heat transfer, and fluid circulation, making it indispensable in rubber vulcanization, plastic molding, extrusion, and thermoforming industries.

Why Choose Our Rotary Union for Rubber and Plastic Molding Machines?

Cost-Effective Alternative

- Our rotary unions provide the same level of performance as Deublin, Kadant, and Maier rotary unions but at a more competitive price.

- Perfect for manufacturers looking to reduce operating costs without sacrificing performance.

Optimized for Rubber & Plastic Applications

- Specifically designed to withstand thermal shock, steam cycling, and abrasive operating conditions common in molding machines.

- Maintains consistent heat distribution, improving molding accuracy and product quality.

Durability & Long Service Life

- Advanced materials ensure resistance against wear, corrosion, and thermal fatigue.

- Helps reduce unplanned downtime and improves overall equipment efficiency (OEE).

Custom Engineering Available

- It can be tailored for multi-passage designs to accommodate different media simultaneously.

- Engineering team available for OEM and ODM solutions.

FAQ

Q1: Can this Rotary Union for Rubber and Plastic Molding Machine handle both hot oil and cooling water?

Yes, it is designed to operate with hot oil, steam, cooling water, air, and hydraulic fluids, making it highly versatile.

Q2: What connection options are available?

We offer threaded, flanged, and customized connections to suit different machine types.

Q3: How does it compare to Deublin rotary unions?

Our rotary unions deliver equivalent performance and reliability but at a more cost-effective price point.

Q4: Do you offer OEM or customized solutions?

Yes, we provide custom-engineered rotary unions based on specific machine and media requirements.

Q5: Is the Rotary Union for Rubber and Plastic Molding Machine suitable for high-speed molding applications?

Yes, with speed ratings up to 3,500 RPM, it performs reliably in fast-cycle molding machines.

Conclusion

If you are seeking a durable, cost-effective, and high-performance rotary union for your rubber and plastic molding machines, this product is the ideal choice. It combines advanced sealing technology, robust construction, and versatile compatibility, ensuring your production line operates with maximum efficiency and minimal downtime.

Whether for tire presses, injection molding, thermoforming, or extrusion, this rotary union provides the reliable fluid transfer solution your operation needs.

Upgrade your molding machine performance today with our Rotary Union for Rubber and Plastic Molding Machine — the smarter, more economical choice for modern manufacturers.