High-Pressure Rotary Union Hydraulic for Industrial Systems

Original price was: $60.00.$55.00Current price is: $55.00.

- Size Range: 1/8″ (DN06) to 1 1/2″ (DN40)

- Maximum Pressure: Up to 400 bar

- Maximum Temperature: Up to 120°C

- Speed Capability: High-speed options available

- Thread Types: LH & RH UNF, Metric, BSP & NPT

Description

Hydraulic Rotary Union Product Overview

Our Rotary Union Hydraulic is engineered for seamless fluid transfer under extreme pressure, temperature, and rotational speed. Designed to transmit hydraulic oil, water-glycol, synthetic fluids, and more between stationary and rotating components, this hydraulic rotary union plays a vital role in heavy machinery, construction equipment, offshore rigs, and industrial automation.

Built with robust materials, precision seals, and high-load bearings, this product ensures leak-free, low-friction performance even in high-demand operations. Whether you need a single-channel rotary union or multi-passage hydraulic swivel, we deliver the performance and durability your system needs. Built for demanding industrial environments, this rotary union delivers superior reliability, leak-free operation, and long service life, making it an essential component for hydraulic systems in manufacturing, automation, and heavy equipment.

Key Features of Hydraulic Rotary Union

Key Features of Hydraulic Rotary Union

Robust Construction for High-Pressure Systems

Crafted from hardened stainless steel or carbon steel housing, the rotary union withstands up to 5000 PSI of hydraulic pressure. The corrosion-resistant body ensures long service life even in hostile outdoor or marine environments.

Leak-Free Sealing Technology

Utilizing high-performance elastomeric seals or mechanical face seals, our union ensures leak-tight fluid transfer across rotating interfaces. This reduces fluid loss, contamination, and potential safety hazards.

Low Friction, High-Speed Operation

Advanced ball or roller bearing configurations allow smooth operation at speeds up to 3000 RPM, minimizing heat buildup and mechanical wear—ideal for dynamic hydraulic actuation systems.

Single & Multi-Passage Options

Choose between single-flow rotary unions for simple hydraulic lines or multi-channel hydraulic rotary joints for complex systems transferring multiple fluids or integrating pneumatic and electrical slip rings.

High-Pressure Hydraulic Compatibility

Designed to handle hydraulic oils and fluids safely under high pressure, ensuring stable fluid transfer without leakage.

Dual or Multiple Passage Options

Available with single or multiple flow channels to accommodate complex hydraulic circuits requiring simultaneous fluid transfer.

Balanced Mechanical Seals

Utilizes premium carbon graphite and tool steel seals that reduce friction and wear, extending seal life and enhancing reliability.

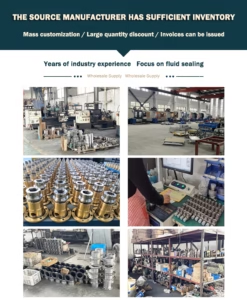

About Our Company

We specialize in manufacturing high-quality hydraulic rotary unions tailored to meet the rigorous demands of industrial hydraulic systems. Our products are engineered for durability, precision, and ease of maintenance, providing cost-effective alternatives to premium brands. With a commitment to customer satisfaction, we offer responsive technical support and customization options to suit your specific application needs.

Applications of Hydraulic Rotary Union

Construction Machinery

Used in excavators, backhoes, cranes, and wheel loaders to transfer hydraulic fluid between rotating carousels or booms and the base.

Offshore and Marine Equipment

Ensures high-pressure hydraulic transfer in winches, deck cranes, and ship stabilizers under saltwater exposure.

Industrial Automation

Powers robotic arms, indexing tables, and hydraulic clamping systems in high-precision production lines.

Agricultural Machinery

Transfers hydraulic oil in harvesters, sprayers, and irrigation rotators with resistance to dirt and impact.

Mining & Drilling Equipment

Withstands extreme pressure and shock in drill rigs, augers, and underground loaders.

Why Choose Our Rotary Union Hydraulic?

Engineered for Harsh Environments

We design our rotary unions to withstand extreme conditions, including high pressure, vibration, and temperature. Whether in construction, mining, or marine industries, our product ensures reliable fluid transfer. The rugged housing and durable seals guarantee long-lasting performance in outdoor and mobile machinery.

Customizable to Any Application

We offer rotary unions with 1 to 12 passages, customizable port sizes, thread types, and media options. From standard hydraulic oil to water-glycol and synthetic blends, we adapt to your fluid system. Need flanged or inline versions? We tailor configurations to meet your machine’s exact requirements.

Field-Proven Durability

Our hydraulic rotary unions are tested in real-world scenarios, including excavators, winders, and drill rigs. Users report continuous operation beyond 10 million rotations without seal failure or leakage. We use high-grade bearings and seals to ensure dependable performance under constant motion.

Zero Leakage Guarantee

Our advanced sealing systems prevent hydraulic oil leaks, even at peak pressure and speed.

We use precision-matched components and balanced mechanical seals to maintain tight tolerances. This ensures environmental safety, fluid conservation, and minimal cleanup or downtime costs.

Fast Lead Times & Global Shipping

We maintain stock for standard rotary union models and fulfill custom orders quickly.

Our logistics network delivers globally with tracking, customs compliance, and prompt service. No matter where your plant is, we ensure your rotary union arrives on time, ready for installation.

Installation and Maintenance Tips

Proper Shaft Alignment

Ensure precise alignment between the rotary union and rotating shaft to prevent uneven seal wear.

Regular Lubrication

Use the oil port to lubricate bearings and seals periodically, especially in continuous operation.

Thread Compatibility

Confirm NPT or BSP thread type before installation to ensure a secure, leak-free connection.

Operating Speed Compliance

Do not exceed the recommended maximum speed of 1000 RPM to maintain seal integrity.

Routine Inspection

Check for signs of leakage or wear and replace seals as necessary to avoid unexpected downtime.

FAQ of Hydraulic Rotary Union

FAQ of Hydraulic Rotary Union

Q1: Can this rotary union handle water-glycol fluids?

Yes, our seals and internal materials are compatible with water-glycol mixtures and other hydraulic media.

Q2: What’s the maximum number of fluid passages available?

Our multi-passage rotary unions support up to 12 independent channels, customizable based on your application.

Q3: Is this rotary union bidirectional?

Yes, it can rotate in both clockwise and counterclockwise directions under pressure.

Q4: Do you provide replacement seal kits?

Absolutely. We offer rebuild kits and technical diagrams for easy servicing.

Q5: Can this replace a Deublin or DSTI hydraulic union?

Yes, we offer fully compatible replacements with matched threads, ports, and performance specs.

Get a Quote or Sample Today

Get a Quote or Sample Today

Optimize your hydraulic system with our reliable, cost-effective rotary union. For custom orders, CAD files, or volume pricing:

📞 Call: +86-15122592153

📩 Email: sales@dannhydraulic.com

🌐 Online Inquiry: www.dannhydraulic.com