Rotary Union Water Rotating Union Water

Original price was: $50.00.$40.00Current price is: $40.00.

- Size:1/4″ – 4″

- Max. speed:3000r/min

- Max. Temperature:80℃/120℃

- Max. Pressure:1.6Mpa

- Connections: Thread

- Standard: METRIC, NPT, BSPT

- Applicable medium: coolant water/hot water/cold oil/air

Description

Product Overview

Product Overview

The Rotary Union for Water (also known as a Water Rotary Joint or Water Swivel Union) is an advanced fluid transfer device engineered to provide a leak-free connection between stationary and rotating parts. It is specially designed for water and coolant media, making it ideal for applications involving water cooling systems, heat exchangers, plastic molding machines, printing cylinders, and textile machinery.

Constructed with corrosion-resistant materials and precision-sealed components, the rotary union ensures smooth, uninterrupted flow of water under both high pressure and high speed. Each unit is dynamically tested to ensure maximum performance, extended service life, and zero leakage.

Working Principle

Working Principle

The Water Rotary Union operates by creating a dynamic seal between the rotating and stationary components. As water flows through the inlet port, it passes through the internal rotary sealing structure and exits via the outlet port—without any leakage.

The precision-balanced internal design ensures continuous fluid transfer while compensating for pressure fluctuations and thermal expansion, making it highly reliable in closed-loop cooling systems.

Key Features

Leak-Free Performance

Advanced mechanical seals and precision-machined components guarantee long-term, leak-proof operation even under high-speed rotation.

Durable Construction

Made from brass, stainless steel, or aluminum, with optional hard chrome or nickel plating to resist corrosion and wear in water-based applications.

High Pressure & Temperature Resistance

Suitable for working pressures up to 10 MPa (100 bar) and temperatures up to 120°C (248°F), depending on model and configuration.

Smooth Rotation & Low Torque

Precision ball bearings minimize friction, allowing stable rotation and energy efficiency in demanding industrial systems.

Customizable Design

Available in single-passage or multi-passage designs to meet various cooling and heating circuit requirements.

Easy Maintenance

Modular seal cartridge design simplifies service and replacement, reducing downtime and operational cost.

Applications of Rotary Union Water

The Rotary Union for Water plays a vital role in industries that rely on efficient cooling, heating, and fluid transfer between stationary and rotating components. Its ability to provide continuous, leak-free water circulation under high speed and pressure makes it indispensable in various industrial automation and process control systems. Below are the main application fields with detailed technical explanations and examples:

Plastic Injection Molding Machines

In plastic molding, temperature control directly affects product quality, cycle time, and material properties. The Water Rotary Union transfers cooling water or oil through the rotating mold to regulate mold temperature precisely.

Printing and Paper Machinery

In rotogravure, offset, and flexographic printing machines, the printing cylinder or chill roll requires precise temperature management to ensure ink consistency and high-quality printing. The rotary union supplies water or glycol coolant to maintain roller temperature, ensuring stable ink viscosity.

Steel, Aluminum, and Metal Rolling Mills

In metal processing industries, water-cooled rotary unions are crucial for cooling rolls, drives, and spindles exposed to extreme heat during rolling operations. Delivers cooling water into rotating rolls to dissipate heat generated by friction and deformation.

Textile Dyeing and Finishing Machines

The textile industry uses rotary unions for temperature regulation in dyeing, printing, and finishing machines. Consistent water flow ensures even dye penetration and fabric finish quality. Transfers hot or cold water into rotating drums or rollers for dye temperature control.

Rubber and Tire Manufacturing

Rubber processing involves high-temperature mixing and curing, where temperature uniformity is critical to product performance. Supplies cooling or heating water to mixing mills, calenders, and curing drums.

Machine Tool Spindles and CNC Systems

In precision machining, spindle cooling is essential to maintain dimensional accuracy and prevent thermal expansion. Circulates water through the rotating spindle or tool holder to remove excess heat.

Food and Beverage Processing

In food production, rotary unions transfer water and steam for heating, cooling, or cleaning purposes under strict hygiene requirements. Supplies clean water for drum heating or cooling during pasteurization and sterilization processes.

Chemical and Pharmaceutical Equipment

Chemical and pharma industries require precise fluid transfer for reactors, dryers, and mixing vessels, often involving hot or chilled water. Transfers temperature-controlled water through rotating vessels for consistent reaction temperature.

Renewable Energy and Power Generation

In turbine cooling or rotating heat exchangers, rotary unions ensure efficient water flow under high pressure and continuous operation. Transfers water or glycol coolant through rotating shafts to manage thermal loads.

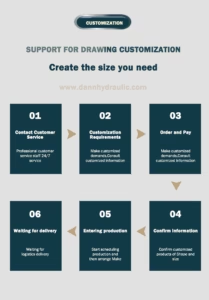

Customization Options

We provide OEM and replacement rotary unions compatible with top brands such as Deublin, Maier, Kadant Johnson, and GAT.

Customization options include:

-

Thread types (BSP, NPT, Metric)

-

Multi-passage configurations

-

High-speed or high-pressure versions

-

Material upgrades for corrosive media

-

Integrated temperature or pressure sensors

If you need a custom rotary union for your cooling system, our engineering team can design one according to your application requirements.

Frequently Asked Questions (FAQ)

Q1: Can this rotary union handle both hot and cold water?

Yes. It is designed for continuous operation with both hot and cold water, with temperature resistance up to 120°C.

Q2: What is the maximum rotation speed?

Depending on the model and bearing type, it can operate up to 3,000 RPM under balanced load conditions.

Q3: How long do the seals last?

Seal life depends on water quality and operating conditions, but typically exceeds 1 million revolutions under standard use.

Q4: Can it be used for other fluids like oil or air?

Although optimized for water and coolant, it can be customized for oil, steam, or compressed air applications.

Q5: Do you provide replacement parts for Deublin or Maier unions?

Yes, we offer fully interchangeable models compatible with major international brands at a more competitive cost.

Conclusion

The Rotary Union Water is the ideal choice for industries requiring reliable, high-performance water transfer solutions. With superior sealing, long-lasting durability, and customizable options, it ensures optimal efficiency for any water-cooled or temperature-controlled system.

Upgrade your production line with our precision-engineered rotary unions, designed to meet the highest standards of performance, reliability, and value.