Rotoflux A10-1771-05L

- Part Number:A10-1771-05L

- Max Operating Pressure: 20 bar (290 psi)

- Max Speed: 10,000 RPM

- Max Temperature: 80 °C (176 °F)

- Connection Type: Threaded or Flanged

- Fluid Compatibility: Water, Oils, Coolants

Description

Key Features

Key Features

Compact Design: It features a compact and lightweight design that facilitates easy installation in tight spaces, making it suitable for a variety of applications.

Versatile Fluid Compatibility: Designed to handle a wide range of fluids, including water, oils, and coolants, the A10 rotary union is adaptable to diverse operational needs across multiple industries.

High-Speed Capability: With the ability to operate at speeds up to 10,000 RPM, this rotary union excels in high-performance applications, providing consistent fluid delivery even under demanding conditions.

Robust Sealing Technology: Equipped with advanced sealing mechanisms, the ROTOFLUX A10 ensures leak-free operation and minimizes maintenance requirements, enhancing overall system efficiency.

Durable Construction: Constructed from high-quality materials, including anodized aluminum and stainless steel options, the rotary union is designed to withstand harsh operating environments and resist corrosion.

Easy Maintenance: The design allows for simple maintenance procedures, ensuring that downtime is minimized and operational efficiency is maximized.

ROTOFLUX A10 Rotary Union: Product Overview

The ROTOFLUX A10 Rotary Union is a premier solution for efficient fluid transfer in rotating applications. Engineered with precision and built to last, this rotary union is ideal for a wide range of industrial settings, ensuring optimal performance and reliability in demanding environments.

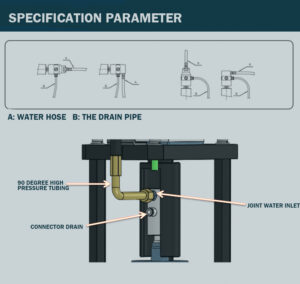

Closed seal, automatic line or similar application

Closed seal, automatic line or similar application

Full flow design, no debris and burr clogging

Bearing support and threaded rotor, easy to install

Deep groove radial ball bearing, smooth operation

Ball bearings are protected by labyrinth seal and large leakage

Balanced machine seal, silicon carbide material, even under harsh working conditions, still can extend the service life;

Corrosion-resistant anodized aluminum parts, high pressure rotary seal replacement, pressure resistance up to 12MPa;

Suitable for high-speed machine spindles and gun drilling (deep hole processing) machine tools and other equipment closed seal, automatic line or similar with

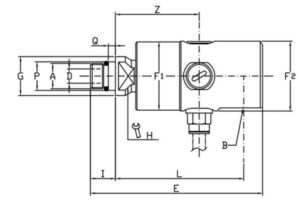

Technical Specifications of ROTOFLUX A10 Rotary Union

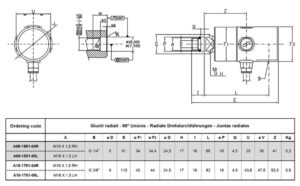

Part Number:A10-1771-05L

Part Number:A10-1771-05L

Max Operating Pressure: 20 bar (290 psi)

Max Speed: 10,000 RPM

Max Temperature: 80 °C (176 °F)

Connection Type: Threaded or Flanged

Fluid Compatibility: Water, Oils, Coolants

Benefits of Using the ROTOFLUX A10 Rotary Union

Enhanced Efficiency: By providing reliable fluid transfer without leaks or interruptions, the ROTOFLUX A10 helps maintain optimal operating conditions in machinery, leading to increased productivity.

Cost Savings: The durable construction and robust sealing technology reduce wear and tear on components, resulting in lower maintenance costs and extended service life for equipment.

Versatility Across Industries: Suitable for various applications including machine tools, packaging machinery, robotics, and automotive manufacturing, the A10 rotary union adapts seamlessly to diverse industrial needs.

Improved Safety: The leak-proof design minimizes the risk of spills and contamination, ensuring a safer working environment for operators and compliance with environmental regulations.

Customizable Solutions: The ROTOFLUX A10 can be tailored to meet specific application requirements with various connection types and configurations available.

The ROTOFLUX A10 Rotary Union significantly enhances productivity in manufacturing through several key mechanisms. Here’s how it achieves this:

Continuous Operation

The ROTOFLUX A10 allows for uninterrupted fluid transfer between stationary and rotating components. This capability eliminates the need for frequent manual intervention or temporary halts in production, which directly contributes to increased uptime and overall productivity in manufacturing processes.

High-Speed Capability

Designed to operate at speeds up to 10,000 RPM, the A10 rotary union is ideal for high-performance applications such as CNC machining and automated assembly lines. Its ability to maintain consistent fluid delivery at high speeds ensures that machinery operates efficiently, thereby enhancing throughput.

Reliable Fluid Transfer

With advanced sealing technology, the ROTOFLUX A10 prevents leaks and ensures a controlled flow of liquids or gases. This reliability not only safeguards product quality but also reduces the risk of environmental hazards associated with fluid spills, fostering a safer and more efficient working environment.

Reduced Wear and Tear

By providing balanced flow for lubricants and cooling materials, the rotary union minimizes friction within machinery. This reduction in wear and tear extends the lifespan of equipment, lowers maintenance costs, and ensures that machines run smoothly over longer periods, all contributing to enhanced productivity.

Versatility Across Applications

The ROTOFLUX A10 is compatible with various fluids, including water, oils, and coolants. This versatility allows it to be used in multiple manufacturing processes—from machining to packaging—making it a valuable asset across different sectors.

Customizable Solutions

Manufacturers can tailor the ROTOFLUX A10 to meet specific operational requirements through various configurations and connection types. This adaptability ensures that it integrates seamlessly into existing systems, optimizing performance without extensive modifications.

Enhanced Safety Features

The leak-proof design of the ROTOFLUX A10 not only protects product quality but also enhances workplace safety by minimizing the risk of spills. This focus on safety can lead to fewer accidents and disruptions in production, further boosting productivity.

Efficient Cooling and Lubrication

In applications where cooling is critical—such as machine tools—the ROTOFLUX A10 provides effective heat management that prevents overheating. Maintaining optimal temperatures during operations enhances equipment efficiency and reliability, which is essential for high-volume production environments. What is the ROTOFLUX A10 Rotary Union?

What is the ROTOFLUX A10 Rotary Union?

The ROTOFLUX A10 is a high-speed rotary union designed for efficient fluid transfer in rotating applications. It is suitable for machine tool spindles and can handle various fluids, including coolants and lubricants, while also being capable of dry running when necessary.

How does the ROTOFLUX A10 handle dry running?

The ROTOFLUX A10 features balanced and micro-lapped seals that remain effective during both wet and dry runs. This design allows it to operate without fluid while maintaining performance, making it versatile for various applications.

What materials are used in the construction of the ROTOFLUX A10?

The rotary union is constructed with an aluminum body and stainless steel rotor, featuring tungsten carbide seals. This combination provides durability and resistance to wear, ensuring long-lasting performance under demanding conditions.

In which industries is the ROTOFLUX A10 commonly used?

The ROTOFLUX A10 is widely used in industries such as:Machine Tool Manufacturing,Automotive Production,Aerospace Engineering,Robotics,Food Processing,These applications benefit from its ability to provide reliable fluid transfer at high speeds.

What are the advantages of using the ROTOFLUX A10 in manufacturing?

The ROTOFLUX A10 enhances productivity by allowing continuous operation without leaks or interruptions, reducing maintenance needs due to its robust design, and providing effective cooling and lubrication during high-speed operations.

How does the design of the ROTOFLUX A10 minimize installation space?

The compact design of the ROTOFLUX A10 allows for easy integration into tight spaces within machinery. This feature is particularly beneficial in applications where space is limited, such as CNC machines.

What maintenance is required for the ROTOFLUX A10?

Regular maintenance involves checking seals for wear, ensuring cleanliness during operation, and verifying that connections are secure to prevent leaks. The design allows for straightforward maintenance procedures to minimize downtime 12.

Can the ROTOFLUX A10 be customized for specific applications?

Yes, the ROTOFLUX A10 can be customized with different connection types and configurations to meet specific operational requirements, making it a flexible solution for various industrial applications.