A10-701 Rotary Joint Rotoflux High Speed Pneumatic Rotary Union

Original price was: $100.00.$91.00Current price is: $91.00.

- Model: A10-1771-05L

- Connection Size: 1/4″ NPT/BSPP (threaded)

- Max Pressure: 20 bar (290 psi)

- Max Speed: 10,000 RPM

- Material: Stainless steel & anodized aluminum

- Sealing Type: Double-lip seals with labyrinth protection

- Temperature Range: -20°C to 80°C

- Media: Compressed air, oils, coolants

- Weight: 0.5 kg

- Applications: CNC machining, automation, robotics, rotary tables

Description

Product Overview

The A10-701 Rotary Joint Rotoflux is a high-performance mechanical component that enables the seamless transfer of various fluids, including liquids, gases, and steam, between stationary and rotating parts of machinery. It acts as a critical connection point, ensuring a continuous and leak-free flow while accommodating rotational movement. This rotary joint features a sophisticated design with a durable stationary housing, a precisely machined rotating shaft, and advanced sealing and bearing systems. These components work in harmony to provide smooth operation, excellent load-bearing capacity, and long-term durability, even in the most challenging operating conditions.

Key Features of A10-701 Rotary Joint Rotoflux High Speed Pneumatic Rotary Union

Key Features of A10-701 Rotary Joint Rotoflux High Speed Pneumatic Rotary Union

Ultra-High Speed & Dry Operation

Capable of dry running at ultra-high rotational speeds, ensuring minimal friction and wear even without coolant flow; Optimized dynamic balance reduces vibration during operation.

Extreme Pressure & Temperature Resistance

Max Pressure for hydraulic systems is 400 BAR (5800 PSI); Temperature Tolerance is -20°C to 120°C (-4°F to 248°F).

Versatile Media Compatibility

Compatible with hydraulic oil, coolant, compressed air, and gases (e.g., inert gases, steam); Constructed from stainless steel, aluminum alloy, or brass (customizable) for corrosion resistance.

Compact & Universal Design

Threaded Installation (M16×1.5L) ensures compatibility with standard industrial interfaces; Compact dimensions simplify integration into existing machinery.

Enhanced Durability

Tungsten carbide seals extend lifespan, even with low-filtration coolants; Spring-loaded mechanism prevents turbulence-induced wear.

Extreme High-Speed Performance

Engineered to handle up to 10,000 RPM, ensuring seamless compressed air transfer in dynamic applications like CNC spindles, robotic arms, and high-speed automation systems.

Heavy-Duty Construction

Crafted from stainless steel with anodized aluminum components, offering exceptional corrosion resistance and durability in harsh industrial environments.

Precision Sealing Technology

Features double-lip seals and labyrinth-protected ball bearings to eliminate leaks and maintain optimal air pressure (up to 20 bar ) for consistent performance.

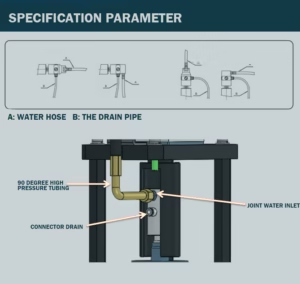

Working pressure, working temperature, and speed:

Working pressure, working temperature, and speed:

–Medium is coolant: 40bar (580PS1), 90°C (195°F), 10000 (RPM) 100 bar (1450PSI), 90°C (195°F), 15000 (RPM)

–Medium is air: 10bar (145PSI), 90°C (195°F), 10000 to 15000 (RPM)

–Dry running 10000 to 15000 (RPM)

Model

A08-1520-04L A08-1520-05L A10-1720-05L A08-1522-04R A08-1522-05L A10-1722-04R A10-1722-05L A10-1771-04R A10-1771-05L A10-1701-05LA1 A08-1501-04R A08-1501-05L A08-1501-11L A08-1520-03R A08-1540-05L BH08-1501-11L

| Item | Value |

|---|---|

| Pressure | 8.0MPA |

| Temperature | -30'C+80°C |

| Speed | <8000RPM |

| Applicable media | Water, coolant, hydraulic oil |

Typical Applications

CNC Machinery

Provides reliable coolant and air transfer to tool heads and rotating spindles.

Printing Presses

Enables smooth fluid and air transfer for web guiding and tension control systems.

Textile Machinery

Supports air and fluid circulation in spinning and weaving operations.

Robotic Arms

Delivers compressed air to pneumatic actuators in high-speed rotational joints.

Automated Assembly Lines

Maintains stable, high-speed air and fluid flow in rotating workstations.

Packaging Equipment

Powers pneumatic components and rotating assemblies in bottling and labeling machines.

Benefits

Enhanced Efficiency

By providing reliable fluid transfer without leaks or interruptions, the ROTOFLUX A10 High Speed Pneumatic Rotary Union helps maintain optimal operating conditions in machinery, leading to increased productivity.

Cost Savings

The durable construction and robust sealing technology reduce wear and tear on components, resulting in lower maintenance costs and extended service life for equipment.

Versatile Applications

Perfect for a variety of industries, from manufacturing to automotive, the Rotoflux A10-1771-05L adapts to your specific needs, providing reliable service across different environments.

Improved Safety

The leak-proof design minimizes the risk of spills and contamination. Ensuring a safer working environment for operators and compliance with environmental regulations.

Customizable Solutions

The ROTOFLUX A10 High Speed Pneumatic Rotary Union can be tailored to meet specific application requirements with various connection types and configurations available.

FAQ

Q1: Can the A10-701 Rotary Joint handle both fluids and air?

Yes, it is compatible with compressed air, water, oil, steam, and coolants.

Q2: What is the maximum operating pressure?

The maximum pressure supported is 145 PSI.

Q3: Is the A10-701 Rotary Joint suitable for high-speed applications?

Yes, it is engineered to handle rotational speeds up to 5,000 RPM.

Q4: How easy is it to install?

The compact, lightweight design allows quick, straightforward installation into most industrial systems.

Conclusion

The A10-701 Rotary Joint Rotoflux is a top-tier product that offers unparalleled performance, reliability, and efficiency in industrial fluid transfer applications. By investing in this rotary union, you’re choosing to enhance your operational capabilities and ensure your equipment performs at its best. Don’t settle for less – elevate your efficiency with the Rotoflux A10-1771-05L High Speed Pneumatic Rotary Union today!