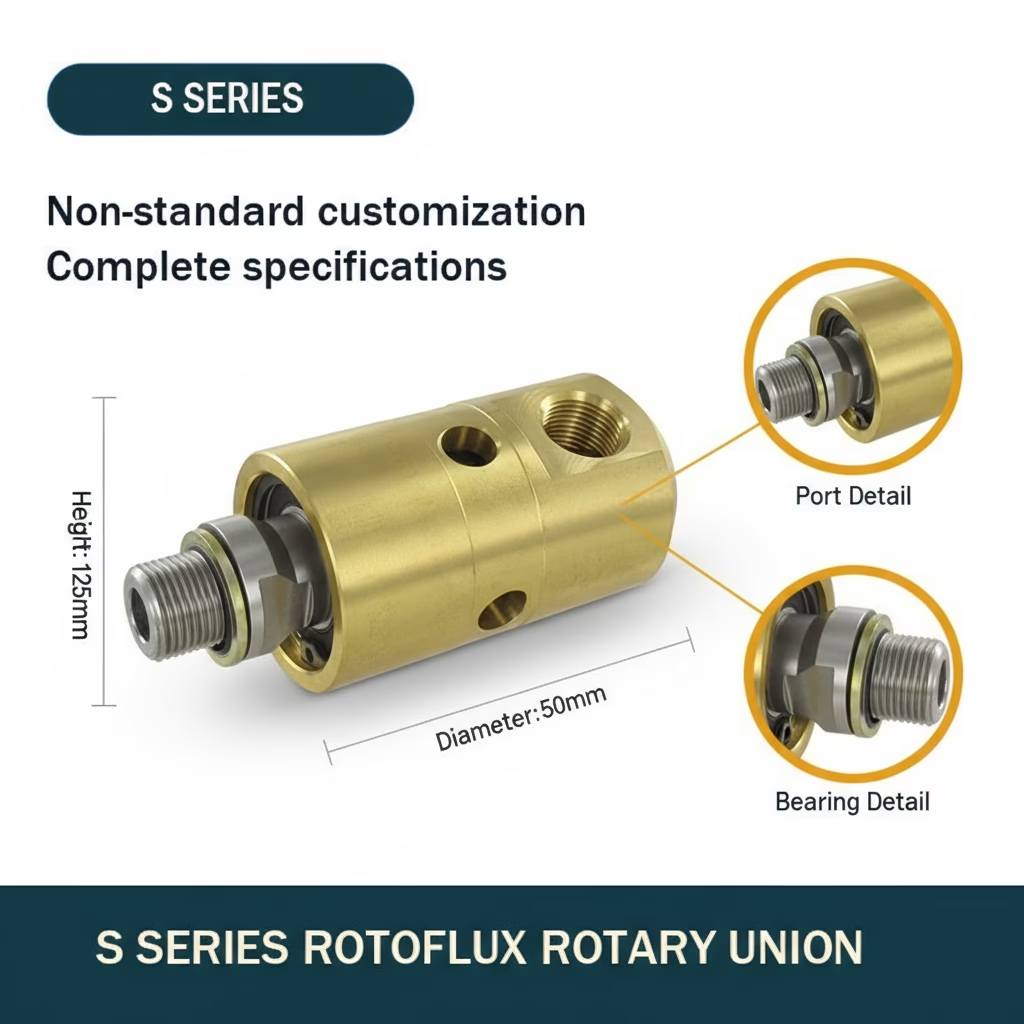

High-Speed Rotoflux S-Serien Rotary Union for Fluid Transfer

Original price was: $80.00.$60.00Current price is: $60.00.

- Max Pressure: 50 bar (750 PSI)

- Max Temperature: 200 °C (392 °F)

- Max Rotation Speed: 3,500 – 7,000 RPM

- Connection Type: BSPP (British Standard Pipe Parallel)

- Materials : Stainless Steel / Brass

Description

ROTOFLUX S-Serien Rotary Union: Product Overview

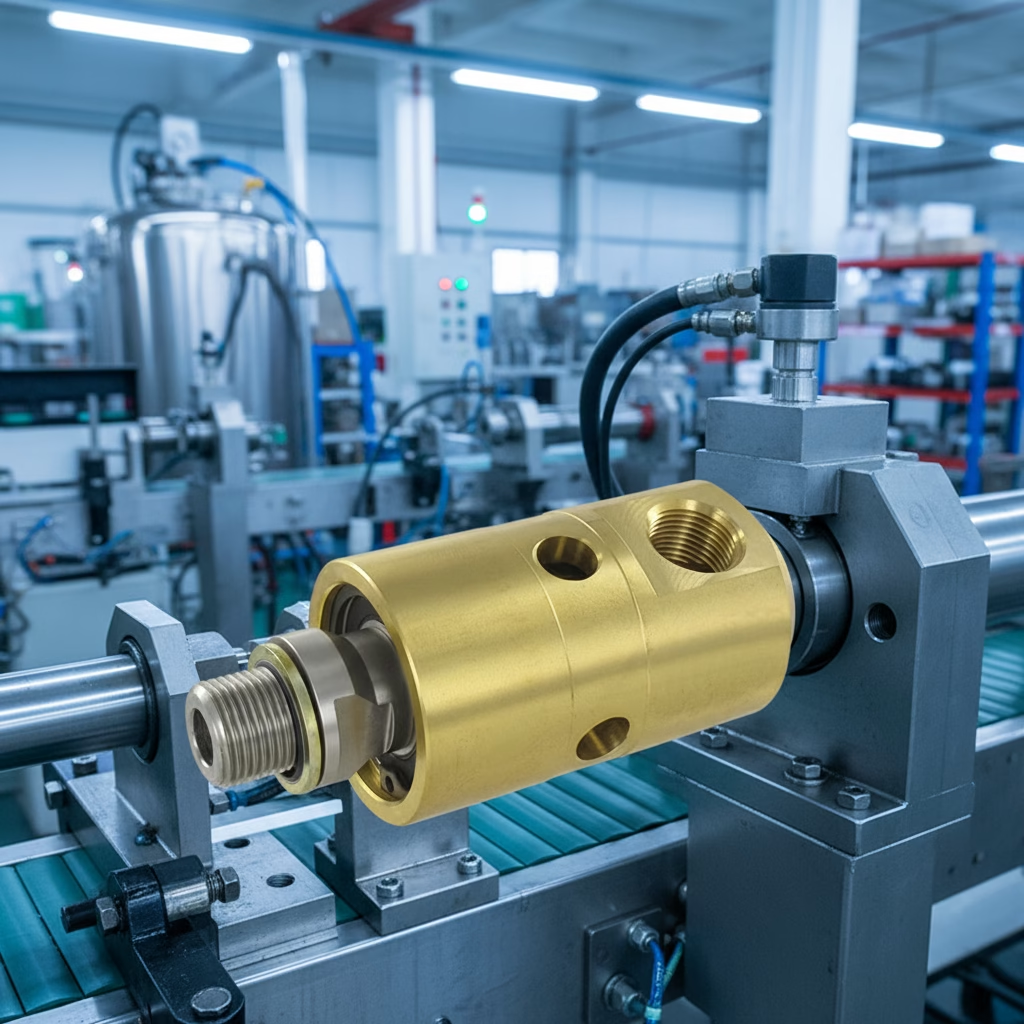

The Rotoflux s-serien rotary union is a high-performance solution designed to facilitate efficient fluid transfer in rotating applications. Engineered for versatility and reliability, this rotary union is perfect for various industrial sectors, including manufacturing, automotive, and energy production. With its innovative design and advanced sealing technology, the S Series ensures optimal performance even in demanding environments.

It is a cutting-edge industrial rotary coupling engineered to deliver unmatched performance in high-speed, high-pressure environments. ROTOFLUX, a global leader in precision rotary joint technology, manufactures the S Series to seamlessly transfer fluids, gases, and air across industries such as CNC machining, hydraulic systems, automation, and chemical processing. With its advanced engineering, robust construction, and leak-free operation, the S Series ensures reliability in extreme conditions, making it a critical component for optimizing machinery efficiency and minimizing downtime.

| Specification | Details |

|---|---|

| Max Rotation Speed | Up to 100,000 RPM |

| Max Pressure | Up to 140 bar (2,030 PSI) |

| Media Compatibility | Emulsion, Oil, Water, Air, Oil-Air Mix |

| Seal Material | Silicon Carbide (hydrostatically released) |

| Housing Material | Precision Steel |

| Bearing System | Spindle or hybrid ball bearings |

| Flow Rate per Channel | 15 - 50 L/min (depending on model) |

| Nominal Diameter | 3.5 mm to 10 mm |

| Operating Temperature | Up to 265°C (509°F) |

Key Features of Rotoflux s-serien Rotary Union

Durable Housing Made from Brass or Aluminum with Stainless Steel Components

RotoFlux engineers the S-Serie rotary union with a high-strength housing made from either brass or lightweight aluminum to ensure long-term durability and corrosion resistance. They use premium-grade stainless steel for all other metallic parts, including the shaft and sealing elements, to deliver excellent wear resistance and reliable performance in demanding environments.

Integrated Spring Mechanism for Vibration and Turbulence Control

To ensure stable and consistent operation, a precision-calibrated internal spring is incorporated to absorb vibrations and reduce fluid-induced turbulence. This helps to maintain smooth rotation even at high speeds or under fluctuating pressure conditions, extending the lifespan of internal components.

Low-Friction Balanced Seal with Micro-Fit Overlap Design

The rotary union features a finely machined micro-overlap seal structure and a dynamically balanced sealing ring. This design minimizes contact friction during rotation, significantly reducing heat generation and power loss. It’s ideal for high-speed applications that demand efficiency and low maintenance.

Oil-Soaked Felt Seal for Reliable Vacuum and Air Operation

When operating in air or vacuum environments, the S-Serie employs a sealed felt ring saturated with lubricant. This smart design ensures consistent sealing performance while maintaining minimal resistance, making it suitable for pneumatic systems or vacuum applications where traditional seals may fail.

You can pass air through the unit at a pressure of 10 kg and a speed of 4000 rpm; the system classifies it as either N-type or D-type.

You can also pass a vacuum at a pressure of 6.7 kg and the same speed of 4000 rpm, with options available in both N-type and D-type configurations.

For hydraulic oil, the unit handles a pressure of 50 kg at 4000 rpm and is also available in N-type and D-type variants.

RotoFlux equips the system with a graphite seal (standard seal) for vacuum and air cooling applications.

For hydraulic oil cooling, RotoFlux uses a D-type tungsten carbide seal designed specifically for heavy-load conditions.

Why Choose the Rotoflux s-serien Rotary Union?

Compact Precision

Optimized for space-constrained machines, the S Series delivers leak-free performance without compromising on accuracy.

Dual-Seal Reliability

Patented dual-seal faces ensure zero media leakage and long service intervals—even under alternating vacuum and pressure cycling.

Fast, Tool-Free Maintenance

Swap out seal cartridges in under 4 minutes—no special tools required—maximizing uptime and reducing maintenance labor.

Versatile Multi-Media Support

One compact unit handles air, water, oil, coolant, vacuum, and inert gases. Simplify your machine architecture and reduce inventory costs.

Applications for the Rotoflux s-serien Rotary Union

Machine Tool Cooling

Description: Machine tools extensively use the S Series to provide essential coolant delivery during machining processes.

Benefits: It helps maintain optimal temperatures, enhances tool life, and improves machining precision by ensuring consistent coolant flow.

Automotive Manufacturing

Description: In automotive assembly lines, the S Series rotary union facilitates fluid transfer in robotic systems and machinery.

Benefits: It ensures reliable operation and efficient fluid management, which is critical for maintaining production speed and quality.

Food Processing Equipment

Description: Food processing applications require this rotary union for essential sanitary fluid transfer.

Benefits: Its robust sealing technology minimizes contamination risks, ensuring compliance with health standards while maintaining operational efficiency.

Textile Machinery

Description: Textile processing machines use the S Series to provide continuous lubrication or cooling

Benefits: It ensures smooth operation by providing reliable fluid transfer, which is critical for preventing wear on machinery.

Plastic Injection Molding

Description: In injection molding machines, the S Series rotary union facilitates cooling during the molding process.

Benefits: It helps maintain optimal temperatures to prevent defects in molded products, enhancing quality control.

Energy Production

Description: The S Series is employed in power generation systems, including turbines and other machinery requiring fluid transfer.

Benefits: It facilitates effective cooling and lubrication, contributing to overall system reliability and efficiency.

Marine Applications

Description: Shipbuilders and maintenance crews use the S Series in cooling systems for marine applications.

Benefits: It provides reliable fluid transfer under challenging conditions, contributing to the longevity and efficiency of marine machinery.

Robotics and Automation

Description: The S Series supports automated systems that require continuous fluid transfer for lubrication or cooling.

Benefits: Its design allows for uninterrupted operation, essential for maintaining productivity in robotic applications.

HVAC Systems

Description: The rotary union can be used in heating, ventilation, and air conditioning systems for fluid management.

Benefits: It ensures efficient circulation of fluids, enhancing the performance of HVAC systems.

Hydraulic Systems

Description: The S Series rotary union is suitable for hydraulic applications where fluid transfer is necessary.

Benefits: It ensures efficient hydraulic fluid management, contributing to the overall performance of hydraulic machinery.

FAQ

What is the S Series ROTOFLUX Rotary Union?

The S Series ROTOFLUX Rotary Union is a specialized component designed for efficient fluid transfer in rotating applications. It is suitable for various fluids, including water, steam, and hot oil, making it versatile for multiple industrial applications such as machine tools, automotive manufacturing, and food processing.

How does the sealing technology work in the S Series ROTOFLUX?

The S Series features advanced sealing technology with balanced and micro-lapped seals. These seals are designed to handle high pressures and abrasive media, ensuring leak-free operation and longevity in various applications.

What industries commonly use the S Series ROTOFLUX?

Industries that benefit from the S Series include: Machine Tool Manufacturing, Automotive Production, Food Processing, Energy Generation, and Textile Manufacturing.

What are the installation requirements for the S Series ROTOFLUX?

Installation requirements include ensuring that the fluid circuit is clean and free from debris, using flexible hoses to avoid stress on the unit, and checking that the rotary union does not rotate eccentrically. Proper lubrication and periodic inspections are also recommended to maintain optimal performance.

Can the S Series ROTOFLUX handle dry running conditions?

Yes, certain models of the S Series are designed to handle dry running conditions effectively. This capability allows for operation without fluid under specific circumstances, making it versatile for various applications.

Conclusion

The Rotoflux s-serien Rotary Union is more than a component – it’s a strategic investment in operational excellence. With unmatched precision, rugged durability, and endless customization possibilities, it empowers industries to push the boundaries of what’s possible in fluid transfer. Trust the choice of leading engineers worldwide – choose the S Series for performance that never compromises.