Hydraulic Stainless Steel Rotary Union Manufacturers

Original price was: $50.00.$38.00Current price is: $38.00.

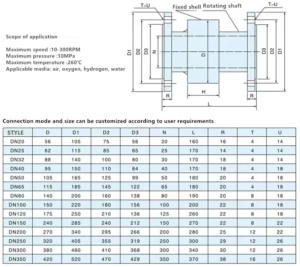

- Product size: from DN20 to DN350

- Maximum pressure: 20 MPa,

- Maximum temperature: 300℃,

- Rotation speed: ≤50 rpm,

- Applicable media: water, steam, oil, air;

- Main material: stainless steel or carbon steel

Description

Stainless Steel Rotary Union – High-Performance Swivel Connector for Industrial Applications

Our stainless steel Rotary Union is engineered to perform superiorly in demanding industrial applications. Crafted from premium AISI 316 stainless steel, this rotary joint offers exceptional durability, corrosion resistance, and operational efficiency. Its flanged design ensures secure connections, making it an ideal choice for applications requiring reliable fluid conveyance under rotating conditions. Designed to provide a reliable fluid transfer between stationary and rotating components, this rotary union ensures leak-free operation under high-pressure and temperature conditions. Crafted from corrosion-resistant stainless steel, it offers exceptional durability and longevity, making it ideal for water, steam, oil, air, and other industrial fluids.

A stainless steel flange rotary joint pipe is a crucial component in various industrial piping systems. It is designed to enable the smooth rotation between two piping sections while maintaining a secure and leak-proof connection. Made from high-quality stainless steel, this type of joint pipe offers excellent resistance to corrosion, high temperatures, and high pressures, making it suitable for a wide range of harsh industrial environments.

Key Feature of Stainless Steel Rotary Union

1 High-Quality Material

Stainless Steel Construction: The pipe manufactured from premium-grade stainless steel, such as 304 or 316 stainless steel. These materials known for their outstanding corrosion resistance, which is essential in environments where the pipe may be exposed to moisture, chemicals, or other corrosive substances. For example, in chemical processing plants, where various corrosive liquids and gases are handled, the stainless steel construction ensures the long-term durability of the joint pipe.

Strength and Durability: Stainless steel has high tensile strength, allowing the joint pipe to withstand high-pressure conditions. Whether in a hydraulic system that operates at high pressures or a steam pipeline where pressure fluctuations are common, the pipe can maintain its structural integrity over an extended period. This reduces the need for frequent replacements, saving both time and money in maintenance and operational costs.

2 Flange Design

Easy Installation: The flange connection design of the rotary joint pipe makes installation and 拆卸 relatively simple. Flanges are commonly used in piping systems because they provide a standardized and reliable way to connect different pipe sections. With appropriate tools and following standard installation procedures, the joint pipe can be quickly attached to the existing piping network, minimizing downtime during system setup or maintenance.

Secure Connection: The flanges are designed to form a tight seal when bolted together. This ensures that there is no leakage of the fluid or gas passing through the pipe. In applications where the fluid being transported is expensive, toxic, or flammable, a secure connection is of utmost importance to prevent environmental pollution, safety hazards, and material waste.

3 Rotary Functionality

Smooth Rotation: The rotary joint allows for 360-degree smooth rotation between the connected piping sections. This is particularly useful in applications where one part of the piping system needs to move relative to another, such as in rotating machinery, conveyors, or swivel joints in industrial equipment. For instance, in a rotary dryer, the rotating drum needs to connected to a stationary steam supply pipe, and the rotary joint enables the continuous supply of steam while allowing the drum to rotate freely.

Reduced Wear and Tear: The design of the rotary joint minimizes friction between the rotating parts. It may incorporate bearings or other lubricated components to ensure smooth movement and reduce wear. This not only extends the service life of the joint pipe but also contributes to the overall reliability of the piping system. Less wear and tear means fewer breakdowns and less frequent maintenance, improving the efficiency of the industrial process.

4 Versatile Applications

Wide Range of Industries: The stainless steel flange rotary joint pipe can used in various industries, including chemical, petroleum, power generation, food and beverage, and manufacturing. In the food and beverage industry, where hygiene is of utmost importance, the stainless steel material is easy to clean and maintain, meeting the strict sanitary standards. In the power generation sector, it can used in steam turbine systems to handle high-temperature and high-pressure steam.

Diverse Fluid Compatibility: It is compatible with a wide range of fluids, including water, steam, oil, chemicals, and gases. The choice of stainless steel grade (such as 304 or 316) can customize based on the specific fluid and environmental conditions to ensure optimal performance and compatibility. For example, 316 stainless steel often used in applications involving seawater or highly corrosive chemicals due to its superior corrosion resistance compared to 304 stainless steel.

Quality Assurance of Stainless Steel Rotary Union

1 Manufacturing Processes

The production of the stainless steel flange rotary joint pipe involves a series of strict manufacturing processes. These include cutting the stainless steel pipes to the required length, machining the flanges to the precise dimensions and surface finishes, assembling the rotary joint components, and performing various tests to ensure the quality and functionality of the product.

2 Testing Procedures

2.1 Pressure Testing

Each joint pipe subjected to pressure testing to ensure that it can withstand the specified maximum working pressure without any leakage. This done by filling the pipe with a suitable fluid (such as water or air) and applying pressure up to the test pressure, which is usually higher than the maximum working pressure, and observing for any signs of leakage or deformation.

2.2 Leakage Testing

In addition to pressure testing, leakage testing carried out using methods such as bubble testing (for air-filled pipes) or using sensitive leak detection instruments. This ensures that the seal between the flanges and the rotary joint is tight and that there is no leakage of the fluid or gas passing through the pipe.

2.3 Rotation Testing

The rotary functionality of the joint pipe tested to ensure smooth rotation at the specified speed and without any abnormal noise or vibration. This is important to ensure that the joint pipe can operate efficiently in the intended applications.

3 Quality Certifications

The product holds various quality certifications, such as ISO 9001. It also complies with relevant industry standards and regulations, providing customers with confidence in the product’s quality and safety.

Applications of Stainless Steel Rotary Union

1 Chemical Industry

In chemical processing plants, these joint pipes used in reactors, distillation columns, and heat exchangers. They allow for the rotation of agitators in reactors while maintaining a tight seal to prevent the leakage of corrosive chemicals. For example, in the production of pharmaceuticals, where precise control of chemical reactions is essential, the reliable performance of the rotary joint pipe ensures the safety and quality of the production process.

2 Petroleum and Gas Industry

In oil refineries and gas processing plants, they use pipelines that connect rotating equipment such as pumps, compressors, and storage tanks. The high-pressure and high-temperature resistance of the stainless steel material is crucial in these harsh environments where petroleum products and gases handled. They also play a role in offshore drilling platforms, where the equipment exposed to saltwater and other corrosive elements, and the joint pipes need to withstand the challenging conditions.

3 Power Generation

In thermal power plants, the rotary joint pipes used in steam turbines and boiler systems. They facilitate the connection between the rotating turbine shafts and the stationary steam pipes, allowing for the efficient transfer of steam while accommodating the rotational movement. In nuclear power plants, where safety is of the highest priority, the reliable sealing and durability of these joint pipes are essential for the proper functioning of the cooling systems and other piping networks.

4 Food and Beverage Industry

In food processing facilities, such as breweries, dairies, and canning plants, the stainless steel construction of the joint pipes meets the strict hygiene standards. They used in conveyor systems, mixing tanks, and filling machines, where the ability to rotate smoothly and easily cleaned is important. For example, in a bottling plant, the rotary joint pipes can used to connect the rotating bottle-filling heads to the stationary liquid supply pipes, ensuring a continuous and hygienic supply of the beverage.

5 Manufacturing Industry

In manufacturing plants, they are used in various types of machinery, such as printing presses, textile machines, and packaging equipment. In a printing press, the rotary joint pipes can used to supply ink or cooling fluids to the rotating cylinders, allowing for smooth operation and high-quality printing. Textile machines help in the rotation of rollers and other moving parts, ensuring the continuous production of fabrics.

FAQ of Stainless Steel Rotary Union

Q: What is the difference between 304 and 316 stainless steel for these joint pipes?

A: 304 stainless steel is a general-purpose stainless steel with good corrosion resistance in most normal environments. 316 stainless steel, on the other hand, contains molybdenum, which gives it better resistance to corrosion in more aggressive environments, such as those involving seawater, chlorides, or certain chemicals. The choice between the two depends on the specific application conditions.

Q: Can these joint pipes used for high-temperature applications?

A: Yes, stainless steel has good high-temperature resistance, and these joint pipes designed to operate within a specified temperature range. However, it is important to check the technical specifications of the specific model to ensure that it is suitable for your intended high-temperature application.

Q: How do I choose the correct flange standard for my piping system?

A: We offer joint pipes with flanges that comply with various international standards. Please consult with our technical team or provide the details of your existing piping system’s flange standards, and we will help you choose the appropriate product.

Q: Can I get a custom-made stainless steel flange rotary joint pipe with specific dimensions?

A: Yes, we offer customization services for dimensions, flange standards, and other specifications to meet your specific needs. Please contact our sales team with your requirements, and we will provide you with a customized solution.