High Pressure Low Speed Stainless Steel Rotating Joint

Original price was: $35.00.$30.00Current price is: $30.00.

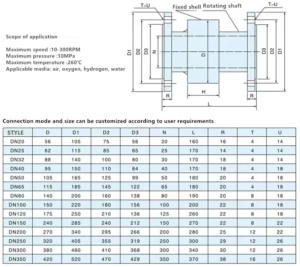

- Model number: DN

- Connection: Male

- Product name: Stainless steel swivel

- Maximum speed: 30RPM

- Maximum temperature:176°C

- Maximum pressure:35MPA

Description

Stainless Steel Rotating Joint: Precision and Performance in Fluid Transfer

The Stainless Steel Rotating Joint is a high-performance component designed to facilitate the seamless transfer of fluids between stationary and rotating parts of machinery. Engineered for durability and reliability, these joints are ideal for various applications, including manufacturing, food processing, and chemical industries. With their robust construction and innovative design, our stainless steel rotating joints ensure efficient fluid management without leakage or contamination.

Key Features and Benefits

Durable Stainless Steel Construction: Crafted from high-quality stainless steel, these rotating joints are resistant to corrosion and wear, ensuring longevity even in harsh environments. This material choice makes them suitable for a wide range of applications, including those involving aggressive fluids.

Multiple Passage Options: Our rotating joints can configured with multiple passages, allowing for the simultaneous transfer of different fluids. This versatility reduces system complexity and enhances operational efficiency by minimizing the number of components required.

Advanced Sealing Technology: Equipped with specialized seals made from materials like graphite, tungsten, and elastomers (Viton, Aflas), these joints prevent fluid leakage and contamination. The micro-lapped mechanical seals ensure a tight fit, providing reliable operation under varying pressure conditions.

Easy Maintenance: Designed with user-friendliness in mind, our stainless steel rotating joints feature a quick-change design that allows for seal replacement without removing the joint from the machine. This reduces downtime and maintenance costs significantly.

High Pressure&Temperature Resistance: Capable of handling pressures up to 16 bar and temperatures ranging from -20°C to +200°C, joints are perfect for demanding industries where reliability is critical.

Stainless steel rotating joints are utilized across various industries:

Manufacturing: Ideal for automated systems where lubricants need to transferred without interruption.

Food and Beverage Industry: Designed to meet stringent hygiene standards, making them perfect for applications in food processing and packaging.

Chemical Processing: Suitable for transferring corrosive chemicals safely and efficiently.

Marine Applications: Used in offshore equipment where reliability under extreme conditions is essential. Why Choose Our Stainless Steel Rotating Joints?

Why Choose Our Stainless Steel Rotating Joints?

At Dann, we offer an extensive range of stainless steel rotating joints that stand out for their quality and performance. Our products come with:

Customizable Designs: Tailored solutions to meet specific operational needs, ensuring optimal performance in any application.

Expert Support: Our knowledgeable team is ready to assist you in selecting the right joint for your requirements, providing guidance on installation and maintenance.

Proven Reliability: Backed by rigorous testing standards, our stainless steel rotating joints designed to deliver consistent performance under demanding conditions.

FAQ

What is a stainless steel rotary union?

A stainless steel rotary union is a mechanical device that allows the transfer of fluids between a stationary inlet and a rotating outlet. It used in applications requiring durability and resistance to corrosion.

What are the applications of stainless steel rotary unions?

Stainless steel rotary unions are used in various industries including food and beverage, pharmaceuticals, printing, and plastics. They facilitate processes such as cooling, heating, and fluid transfer in machinery like extruders, mixers and printing presses.

How do I choose the right stainless steel rotary union for my application?

When selecting a stainless steel rotary union, consider factors such as the type of fluid being transferred, pressure and temperature ratings, connection types, and the specific requirements of your machinery.

What maintenance required for stainless steel rotary unions?

Regular maintenance is essential to prevent issues like leakage or blockage. This includes inspecting seals, checking for wear and tear, and ensuring proper alignment during installation to avoid side loading.

What is the typical lifespan of a stainless steel rotary union?

The lifespan of a stainless steel rotary union varies based on usage conditions such as speed, pressure and maintenance practices. Generally, they can last several years before requiring replacement or refurbishment.

Are there different types of seals used in stainless steel rotary unions?

Yes, stainless steel rotary unions can utilize various sealing technologies including mechanical seals, O-rings, and hydrostatic seals. The choice of seal depends on factors like fluid type and operating conditions.

What common problems associated with stainless steel rotary unions?

Common issues include leakage due to worn seals, blockages from debris in the fluid media and premature wear from excessive speed or improper installation. Regular inspections can help mitigate these problems.